Purpose, malfunctions and repair of the clutch master cylinder VAZ 2101

Content

All classic "Lada" have the same design of the clutch mechanism. One of the main components in the hydraulic drive system is the clutch master cylinder, through which the release bearing is controlled. Replacement of the hydraulic drive is carried out in case of breakdown or failure of the mechanism.

Clutch master cylinder VAZ 2101

The stable operation of the clutch master cylinder (MCC) has a direct impact on the functioning of the gearbox and its service life, as well as the smoothness of gear changes. If the hydraulic drive breaks down, the control of the box becomes impossible, as well as the further operation of the car.

What is it for

The main function of the GCC is to briefly disconnect the power unit from the gearbox when shifting gears. When you press the pedal, pressure is created in the system, which acts on the clutch fork rod. The latter drives the release bearing, controlling the clutch.

How it works

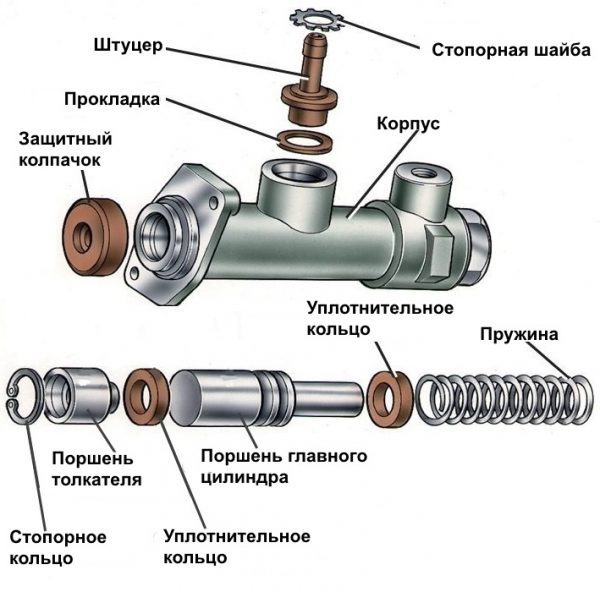

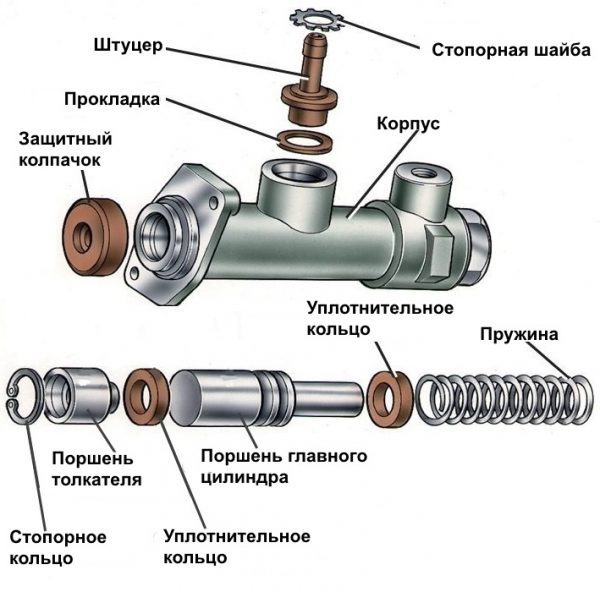

The main components of the node are:

- outer cuff;

- sealing cuff;

- fitting;

- stock;

- returnable spring;

- the body;

- cover for protection.

Principle of operation

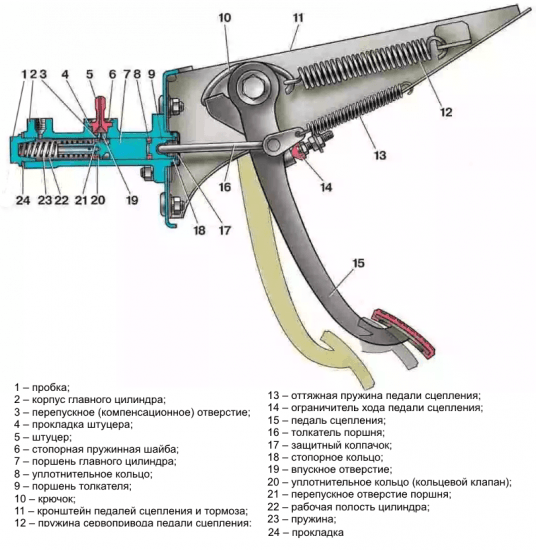

The hydraulic clutch consists of two cylinders - main and working (HC and RC). The principle of operation of the hydraulic drive is based on the following:

- The liquid in the HC enters through a hose from the tank.

- When acting on the clutch pedal, the force is transmitted to the rod by means of a pusher.

- The piston in the HC extends, which leads to valve overlap and fluid compression.

- After the liquid is compressed in the cylinder, it enters the hydraulic system through the fitting and is fed to the RC.

- The slave cylinder drives the fork, which moves the clutch with the release bearing forward.

- The bearing presses on the friction spring of the pressure plate, releasing the driven disc, after which the clutch is turned off.

- After the pedal is released, the piston of the cylinder returns to its original position under the influence of a spring.

Where is

The GCC on the VAZ 2101 is installed under the hood near the vacuum brake booster and the master cylinder of the brake system. Near the clutch cylinder there are also tanks: one for the braking system, the other for the hydraulic clutch.

When a replacement is needed

The elements of the cylinder wear out over time, which leads to interruptions in the operation of the mechanism. Repair or replacement of the GCC is needed when the following symptoms appear:

- airiness of the system;

- leakage of working fluid;

- wear of the cylinder components.

The presence of air in the hydraulic drive system disrupts the performance of the system, making it impossible to function. Air can enter the hydraulic drive through microcracks in the sealing elements of the cylinder or in the connecting hoses. If a system check reveals a constant lack of fluid in the expansion tank, the entire clutch mechanism must be inspected, since fluid can leave not only the master cylinder. If there is insufficient fluid in the hydraulic drive system, the necessary pressure to move the clutch fork cannot be formed. Such a problem will manifest itself in the inability to separate the motor and gearbox when the clutch pedal is pressed. If the leak is caused by wear on the connecting hoses, then replacing them is not a problem. If the problem is related to the GCC itself, then the product will have to be dismantled, disassembled and find out the cause, or simply replace the part with a new one.

Which one is better to put

On the VAZ 2101, it is necessary to install a clutch hydraulic actuator designed for the VAZ 2101–07. Cylinders designed to work in UAZ, GAZ and AZLK vehicles are not suitable for installation on a "penny". A similar situation with imported counterparts. It will be quite problematic to introduce GCC from any foreign car, due to different fastening of the assembly, different threads and tube configuration. However, a hydraulic drive from a VAZ 2121 or from a Niva-Chevrolet is suitable for the "classic".

Manufacturer selection

Today, there are many companies that manufacture clutch master cylinders. However, when choosing and buying the node in question, preference should be given to such manufacturers:

- JSC AvtoVAZ;

- Brik LLC;

- LLC "Kedr";

- Fenox;

- ATE;

- TRIALLI.

The average cost of a hydraulic clutch is 500–800 rubles. However, there are products that cost about 1700 rubles, for example, cylinders from ATE.

Table: comparison of hydraulic clutch actuators from different manufacturers by price and reviews

| Manufacturer, country | Trademark | Cost, rub. | Reviews |

| Russia, Togliatti | AvtoVAZ | 625 | Original GCCs are made with high quality, they are more expensive than analogues |

| Belarus | Fenox | 510 | Original GCCs are inexpensive, made with high quality, popular among drivers |

| Russia, Miass | Brick Basalt | 490 | Improved design: the absence of a technological plug at the end of the cylinder and the presence of an anti-vacuum cuff increase the reliability of the product |

| Germany | AND THOSE | 1740 | The originals are of the highest quality. The price is tied to the EURO exchange rate |

| Germany | HORT | 1680 | Original GCCs are reliable and durable in operation. The price is tied to the EURO exchange rate |

| Russia, Miass | Cedar | 540 | The original GCCs do not cause any particular complaints |

Clutch Master Cylinder Repair

If you do not pay attention to the poor performance of the clutch, then wear of the teeth on the gears of the gearbox is quite likely, which will lead to the failure of the unit. Repair of the box will require much more time and material investments. Therefore, if there are signs of malfunctions with repairs, it is not worth delaying. To work, you will need the following tools:

- key on 10;

- socket head 13 with extension;

- screwdriver;

- wrench 13 for brake pipes;

- rubber pear for pumping liquid;

- repair kit for HCS.

Withdrawal

The dismantling of the cylinder is carried out in the following order:

- We unscrew the fastening of the expansion tank of the cooling system, since it blocks access to the hydraulic drive.

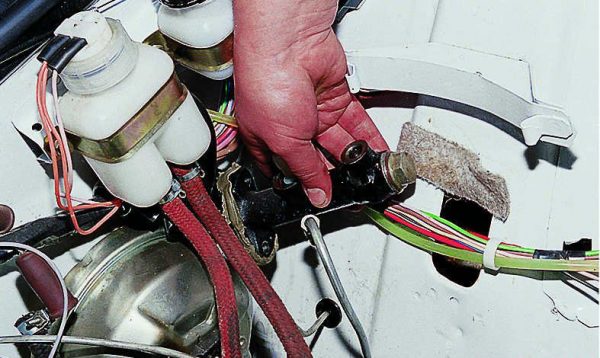

The expansion tank makes it difficult to access the GCS, so the tank must be dismantled

The expansion tank makes it difficult to access the GCS, so the tank must be dismantled - Set the container aside.

Unscrew the tank mount, remove it to the side

Unscrew the tank mount, remove it to the side - With a rubber bulb or syringe, remove the fluid from the clutch reservoir.

Using a bulb or syringe, we pump out the brake fluid from the reservoir

Using a bulb or syringe, we pump out the brake fluid from the reservoir - We unscrew the fastening of the bar holding the tank.

The GCC fluid tank is attached to the body with a bar, unscrew its mount

The GCC fluid tank is attached to the body with a bar, unscrew its mount - With a key of 13, we unscrew the tube that goes to the working cylinder, after which we take it to the side.

We unscrew the tube going to the clutch slave cylinder with a key of 13

We unscrew the tube going to the clutch slave cylinder with a key of 13 - Loosen the clamp and remove the GCS hose.

We loosen the clamp and remove the hose for supplying the working fluid from the fitting

We loosen the clamp and remove the hose for supplying the working fluid from the fitting - With a 13 head with an extension cord or a key, we unscrew the hydraulic drive mount, carefully removing the washers from the studs.

We unscrew the fastening of the GCC to the engine shield

We unscrew the fastening of the GCC to the engine shield - We dismantle the cylinder.

Having unscrewed the fasteners, we dismantle the cylinder from the car

Having unscrewed the fasteners, we dismantle the cylinder from the car

Disassembly

From the tools you need to prepare:

- key on 22;

- Phillips or flathead screwdriver.

The procedure is performed in the following sequence:

- We clean the outside of the cylinder from contamination with a metal brush so that no debris gets inside during disassembly.

- We clamp the hydraulic drive in a vice, unscrew the plug with a key of 22 and remove the spring.

Clamping the clutch hydraulic drive in a vice, unscrew the plug

Clamping the clutch hydraulic drive in a vice, unscrew the plug - We tighten the anther and remove the retaining ring.

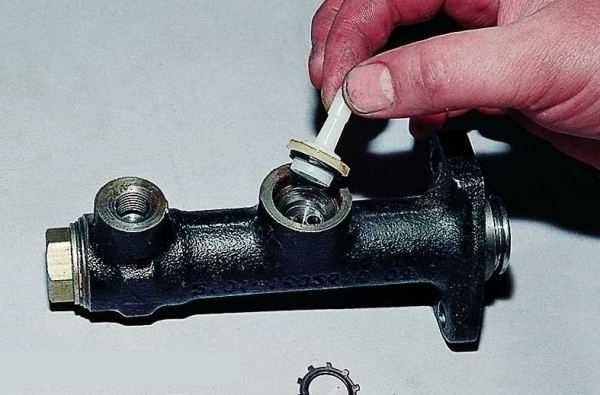

On the reverse side of the cylinder, remove the anther and remove the retaining ring

On the reverse side of the cylinder, remove the anther and remove the retaining ring - Using a screwdriver, push the piston towards the stopper.

The GCC piston is squeezed out with a screwdriver

The GCC piston is squeezed out with a screwdriver - We hook the lock washer and remove the fitting from the socket.

Prying the lock washer, remove the fitting from the socket

Prying the lock washer, remove the fitting from the socket - We carefully fold all the internal elements next to each other so as not to lose anything.

After disassembling the clutch cylinder, carefully arrange all the parts next to each other

After disassembling the clutch cylinder, carefully arrange all the parts next to each other

Do not use metal objects or sandpaper to clean the cylinder body from dirt inside. Only brake fluid and a rough cloth can be used. For the final flushing of the assembly, we also use brake fluid and nothing else.

When carrying out repair work with clutch or brake cylinders, after disassembling the device, I inspect the internal cavity. On the inner walls of the cylinders there should be no scoring, scratches or other damage. Installing new parts from the repair kit will not give any result and the GCC will not work properly if the inner surface is scratched. The same applies to the piston surface. Otherwise, the cylinder will have to be replaced with a new part. If there are no flaws, then the result of the repair will be positive.

Cuff replacement

With any repair of the clutch master cylinder, which involves disassembling it, it is recommended to change the rubber elements.

To do this, perform the following steps:

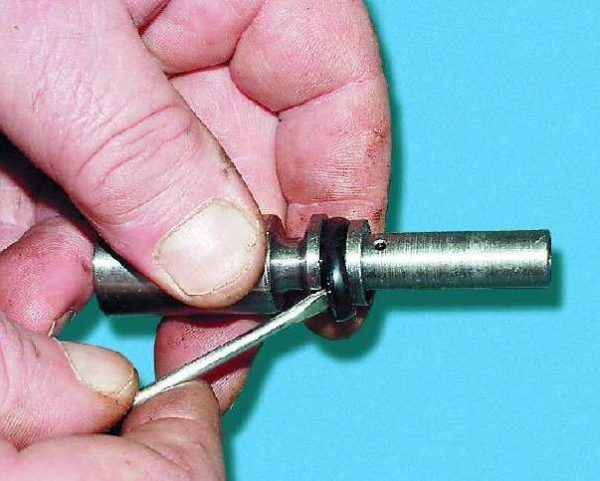

- We pull the cuffs off the piston, prying them with a screwdriver.

To remove the cuffs from the piston, it is enough to pry them with a flat screwdriver

To remove the cuffs from the piston, it is enough to pry them with a flat screwdriver - We wash the piston with brake fluid, cleaning the part from rubber residues.

- We install new seals in place, carefully helping with a screwdriver.

When installing the cuffs, the matte side of the rubber elements must be turned towards the cylinder rod.

Assembly

The assembly process is carried out in reverse order:

- Flush the inside of the cylinder with clean brake fluid.

- Lubricate the cuffs and piston with the same liquid.

- Insert the pistons into the cylinder.

- We install the retaining ring in place, and on the other side of the GCC we insert the spring.

We insert the retaining ring into the GCC body using round-nose pliers

We insert the retaining ring into the GCC body using round-nose pliers - We put a copper washer on the plug and screw the plug into the cylinder.

- Installation of the GCC to the motor shield is carried out in the reverse order of removal.

Video: GCC repair on the "classic"

Clutch bleeding

In order to eliminate the possibility of failure of the clutch mechanism, after the repair is completed, the hydraulic drive system must be pumped. To carry out the procedure, the car must be installed on a flyover or inspection hole, and also prepared:

- brake fluid;

- wrenches for unscrewing brake pipes;

- rubber tube of suitable diameter;

- transparent container.

What liquid to fill

For classic "Zhiguli" in the hydraulic clutch system, the factory recommends using RosDot 4 brake fluid. A container with a volume of 0,5 liters will be enough for repairs. The need to fill the liquid may arise not only during repair work, but also when replacing the liquid itself, since over time it loses its properties.

How to bleed the clutch

Work is best done with an assistant. The liquid level in the tank should be under the neck. We perform the following steps:

- We pull one of the ends of the hoses onto the fitting of the clutch slave cylinder, and lower the other into the container.

- The assistant presses the clutch pedal several times until it becomes tight, and holds it in the depressed position.

The assistant, who is in the cabin, presses the clutch pedal several times and keeps it pressed

The assistant, who is in the cabin, presses the clutch pedal several times and keeps it pressed - We unscrew the fitting and lower the liquid with air into the container, after which we twist the fitting.

To bleed the hydraulic drive system, it is necessary to unscrew the fitting and release the fluid with air bubbles

To bleed the hydraulic drive system, it is necessary to unscrew the fitting and release the fluid with air bubbles - Repeat the procedure several times until air is completely expelled from the system.

Video: pumping the clutch on the classic Zhiguli

Watch this video on YouTube

In the process of pumping, the fluid from the clutch reservoir will leave, so its level must be monitored and topped up as necessary.

Breakdown of the clutch master cylinder VAZ 2101 is a rare phenomenon. If problems arise, they are associated with damage to the anther or the use of low-quality fluid. If the mechanism malfunctions, you can restore the working capacity on your own. To carry out repair work, you need to prepare the necessary tools and read the step-by-step instructions, which will eliminate possible errors.