Purpose, type and design of fuel filters

Content

- Design and types

- Features of filtration systems for various types of engines

- Fuel purification systems for gasoline engines

- Cleaning systems for diesel engines

- Types of diesel fuel filters

- Diesel coarse filter

- Separator-water separator

- Slows down and calms the flow of fuel, separating the water contained in it. Partially eliminates impurities with a particle size of more than 30 microns (rust suspended in water). The design is collapsible, allows you to remove the labyrinth-disk water separator for cleaning.

- Fine filter

- How to install and filter resource

Where does dirt in fuel come from?

Once again visiting the gas station, read the "certificates of quality" displayed at the checkout window.

Gasoline AI-95 "Ekto plus" is considered to be of high quality if it contains no more than 50 mg / l of resin, and after its evaporation, the dry residue (contamination?) does not exceed 2%.

With diesel fuel, too, not everything is smooth. It allows water up to 200 mg/kg, total pollution 24 mg/kg and sediment 25 g/m3.

Before getting into the tank of your car, the fuel was repeatedly pumped over, poured into different containers, transported to the oil depot, pumped again and transported. How much dust, moisture and "general pollution" got into it during these procedures, only fuel filters know.

Design and types

The fuel line of any engine begins with a fuel intake with a coarse mesh filter (hereinafter CSF) installed at the very bottom of the fuel tank.

Further, depending on the type of engine - carburetor, injection gasoline or diesel, on the way from the tank to the fuel pump, the fuel goes through several more stages of purification.

Fuel intakes and fuel modules with CSF are located at the very bottom of the tank.

CSF diesel engines are mounted on the frame or bottom of the car body. Fine filters (FTO) for all types of engines - in the engine compartment.

Cleaning quality

- Mesh fuel inlets trap particles larger than 100 microns (0,1 mm).

- Coarse filters - larger than 50-60 microns.

- PTO of carburetor engines - 20-30 microns.

- PTO of injection motors - 10-15 microns.

- The PTF of diesel engines, which are the most demanding for fuel purity, can screen out particles larger than 2-3 microns.

There are diesel PTF with a screening purity of 1-1,5 microns.

Filter curtains for fine cleaning devices are mainly made of cellulose fibres. Such elements are sometimes called "paper elements", they are cheap and easy to manufacture.

The uneven structure of cellulose fibers is the reason for the variation in the permeability of the "paper" curtain. The cross section of the fibers is greater than the gaps between them, this reduces the "dirt capacity" and increases the hydraulic resistance of the filter.

The highest quality filter curtains are produced from polyamide fibrous material.

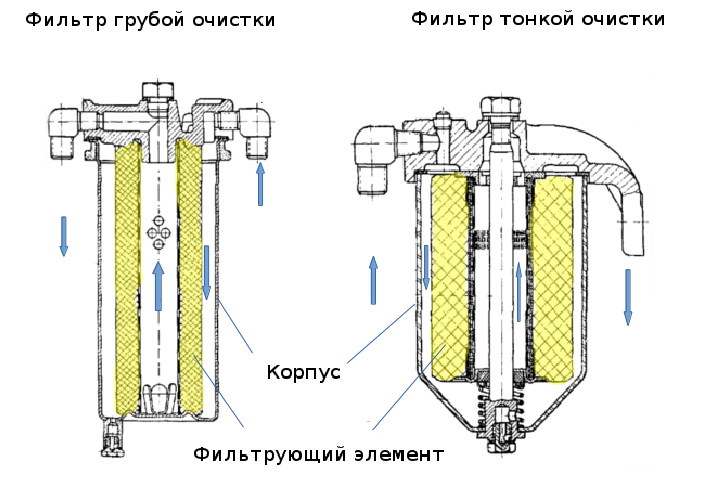

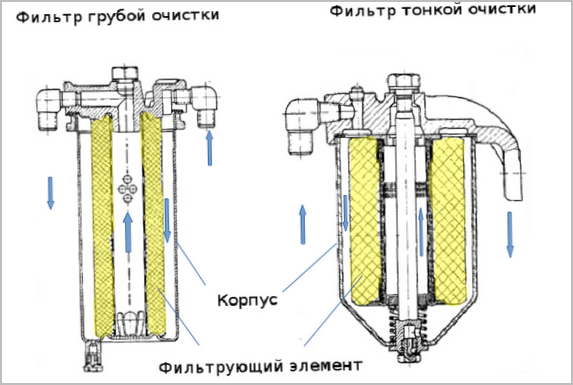

The filtering curtain is placed in the body like an accordion ("star"), which provides a large filtration area with small dimensions.

Some modern PTOs have a multi-layer curtain of variable permeability, decreasing in the direction of the medium flow. Indicated by the marking "3D" on the case.

PTOs with spiral stacking of filter curtains are common. Separators are installed between the turns of the spiral. Spiral PTOs are characterized by high productivity and cleaning quality. Their main disadvantage is their high cost.

Features of filtration systems for various types of engines

Fuel purification systems for gasoline engines

In the power supply system of the carburetor motor, after the grid in the gas tank, a sump filter is additionally installed in the line. After it, the fuel passes through the mesh in the fuel pump, the fine filter (FTO) and the mesh in the carburetor.

In gasoline injection engines, the fuel intake, coarse and medium filters are combined with a pump in the fuel module. The supply line ends under the hood with the main PTO.

Coarse filters

CSF fuel intakes are collapsible, made of brass mesh on a rigid frame.

Submersible fuel module filters are formed from two or three layers of polyamide mesh, providing coarse and medium fuel cleaning. The mesh element cannot be washed or cleaned and, if contaminated, is replaced with a new one.

FGO-settlers are collapsible. The cylindrical filter element installed in a metal housing is made of a brass mesh or a set of perforated plates, sometimes of porous ceramics. In the lower part of the body there is a threaded plug for draining the sediment.

Filter-sumps of carburetor engines are mounted on the frame or bottom of the car body.

Fine filters

In passenger cars, filters of this type are installed under the hood. FTO carburetor motor - non-separable, in a transparent plastic case that can withstand pressure up to 2 bar. For connection to hoses, two branch pipes are molded on the body. The direction of flow is indicated by an arrow.

The degree of contamination - and the need for replacement - is easy to determine by the color of the visible filter element.

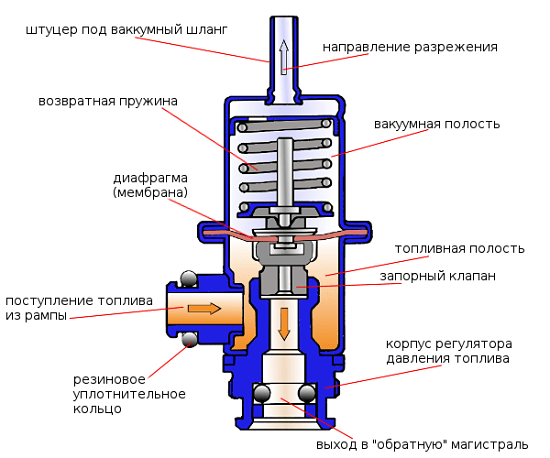

The PTO of an injection gasoline engine operates under pressure up to 10 bar, has a cylindrical steel or aluminum body. Housing cover molded or made of durable plastic. Branch pipes are steel, the direction of a stream is designated on a cover. The third branch pipe, installed in the cover, connects the filter with a pressure reducing (overflow) valve, which dumps excess fuel into the "return".

The product is not disassembled or repaired.

Cleaning systems for diesel engines

The fuel that feeds the diesel engine, after the grid in the tank, passes through the CSF-sump, separator-water separator, FTO, the grid of the low-pressure pump and the high-pressure fuel pump.

In passenger cars, the fuel intake is installed at the bottom of the tank, CSF, separator and FTO are under the hood. In diesel trucks and tractors, all three devices are mounted on the frame in a common unit.

The plunger pairs of the low-pressure booster pump and high-pressure fuel pump, as well as the spray nozzles of diesel engines, are very sensitive to any fuel contamination and the presence of water in it.

The ingress of solid abrasive particles into the precision gaps of plunger pairs causes their increased wear, water washes away the lubricant film and can cause scuffing of friction surfaces.

Types of diesel fuel filters

The mesh of the fuel intake is brass or plastic; it retains dirt particles larger than 100 microns. The mesh can be replaced when the tank is opened.

Diesel coarse filter

All modern devices are collapsible. Filter out contaminating fractions of 50 or more microns. A replaceable element (glass) with a "paper" curtain or from several layers of plastic mesh.

Separator-water separator

Slows down and calms the flow of fuel, separating the water contained in it. Partially eliminates impurities with a particle size of more than 30 microns (rust suspended in water). The design is collapsible, allows you to remove the labyrinth-disk water separator for cleaning.

Fine filter

Very high degree of filtration, retains fine particles ranging in size from 2 to 5 microns.

The device is collapsible, with a removable housing. The removable glass of modern devices has a polyamide fiber curtain.

Removable cases are made of steel. Sometimes a durable transparent plastic is used as the body material. Under the replaceable element (cup) there is a chamber for accumulation of sludge, in which a drain plug or valve is installed. The housing cover is light-alloy, cast.

In "fancy" cars, a circuit for monitoring the condition of the filter is provided. The sensor, which is triggered when the chamber is overfilled, turns on a red control light on the dashboard.

At low temperatures, paraffinic hydrocarbons dissolved in diesel fuel thicken and, like jelly, clog the curtains of the filter elements, preventing the flow of fuel and stopping the engine.

In modern diesel vehicles, filtering devices and a water separator are installed in the engine compartment or in a single unit on the frame, heated with antifreeze from the cooling system.

In order to prevent the "freezing" of diesel fuel, electric thermoelements operating from the on-board network can be installed on the fuel tank.

How to install and filter resource

It is recommended to inspect and wash the fuel intake grids and the CSF-sump whenever the fuel tank is opened. Kerosene or solvent can be used for flushing. After washing, blow off the parts with compressed air.

Disposable filters of carburetor units are replaced every 10 thousand kilometers.

All other filtering devices or their replaceable elements are changed "by mileage" in accordance with the vehicle's operating instructions.

The durability of the device depends on the quality of the fuel used.

The transparent case facilitates diagnostics. If the traditional yellow color of the curtain has changed to black, you should not wait for the recommended period, you need to change the removable element.

When replacing any fuel filters, detachable tubes or hoses should be closed with temporary plugs to prevent air from entering the system. Upon completion of work, pump the line with a manual device.

When replacing the collapsible filter element, the removed housing should be washed and blown out from the inside. The same should be done with the separator housing. The water separator removed from it is washed separately.

The method of laying the filter curtain, "star" or "spiral", determines the quality of cleaning, not the service life of the device.

External signs of clogged filters are similar to other malfunctions of fuel system components:

- The engine does not develop full power, lazily reacts to a sharp pressing of the accelerator pedal.

- Idling is unstable, the "engine" strives to stall.

- At a diesel unit, under heavy loads, black smoke comes out of the exhaust pipe.