Battery not charging

Content

- The main reasons why the battery may not charge

- How do you know if the battery is not charging?

- The car battery is not being charged by the generator. Why?

- Because of what the battery may not be charged from the charger

- What can you do when your car battery is not charging?

- Causes of breakdown of starter machine batteries

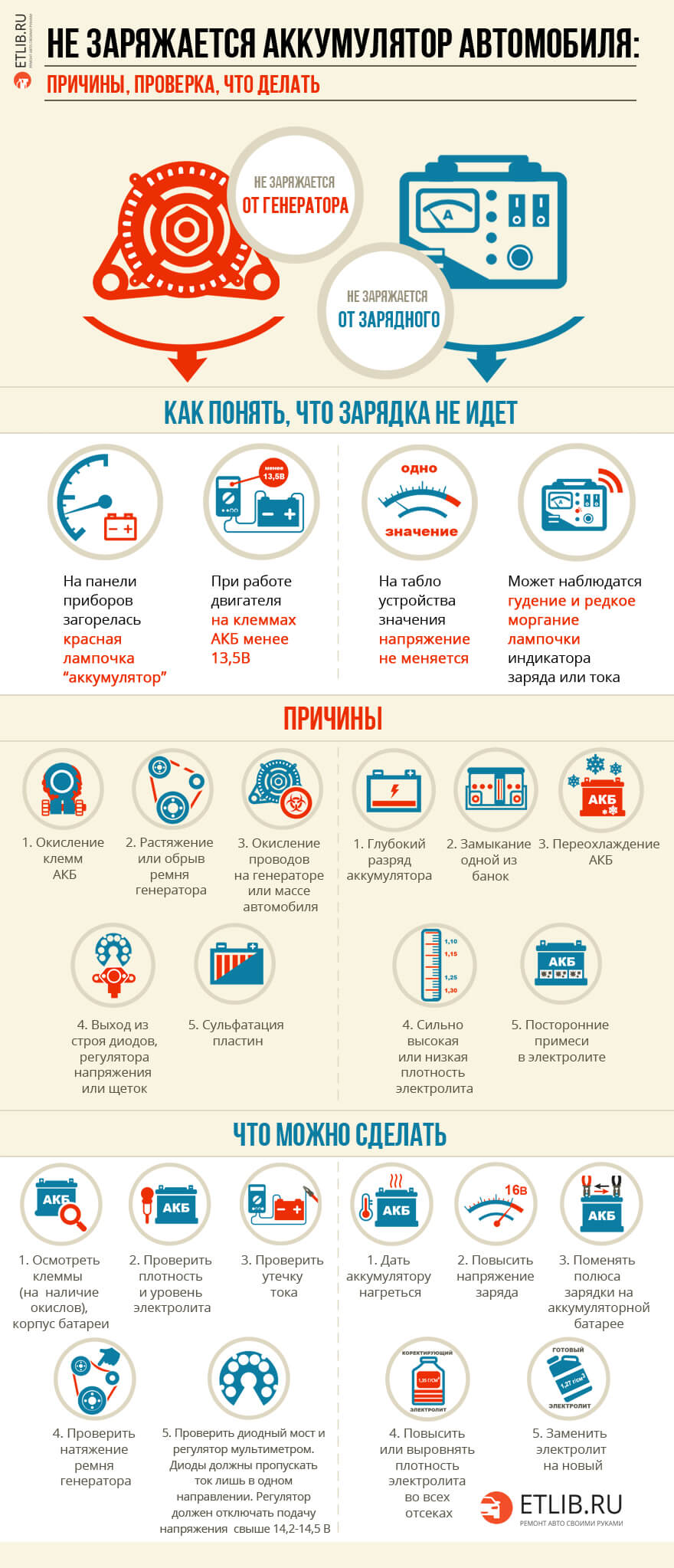

- Graphical representation of the situation when the battery is not being charged. Infographics

If the battery is not charging, which is already more than 5-7 years old, then the answer to the question: - “why?” lies most likely on the surface. After all, any battery has its own service life and over time loses some of its basic performance characteristics. But what if the battery has served no more than 2 or 3 years, or even less? Where then to look reasons Why won't the battery charge? Moreover, this situation appears not only when recharging from a generator in a car, but even when replenished by a charger. Answers need to be sought depending on the situation by doing a series of checks followed by procedures to correct the problem.

Most often, you can expect 5 basic reasons that manifest themselves in eight different situations:

| Situation | What to produce |

|---|---|

| Oxidized terminals | Clean and lubricate with special grease |

| Broken/loose alternator belt | Stretch or change |

| Broken diode bridge | Change one or all diodes |

| Defective voltage regulator | Replace graphite brushes and regulator itself |

| Deep discharge | Increase the charging voltage or perform a polarity reversal |

| Incorrect electrolyte density | Check and bring to the desired value |

| Sulfation of plates | Perform a polarity reversal, and then several cycles of full charge / discharge with a small current |

| One of the cans is closed | Actions to restore a battery with such a defect are ineffective |

The main reasons why the battery may not charge

in order to deal in detail with all the possible malfunctions due to which the car battery is not charging, first of all, clearly define the situation:

| the battery quickly discharges and runs out | or he | does not charge at all (does not take charge) |

In general, when the battery refuses to charge, the following options are allowed:

- sulfation of plates;

- destruction of plates;

- oxidation of terminals;

- decrease in the density of the electrolyte;

- closure.

But you shouldn’t worry so much right away, everything is not always so bad, especially if such a problem arose while driving (the red battery light signals). It is necessary to consider special cases in which the machine battery does not take a charge only from the generator or from the charger as well.

There are a number of external devices in the car battery charging system, which can also greatly affect the performance of the battery itself and the charging process. in order to check all external devices, you will need a multimeter (tester), it will allow you to measure the voltage at the battery terminals under different operating modes of the internal combustion engine. And you will also have to check the generator. But this is only true when the battery does not want to be charged from the generator. If the battery does not take a charge from the charger, then it is also desirable to have a hydrometer to check the density of the electrolyte.

How do you know if the battery is not charging?

The battery does not charge from the generator. The first signal that the battery is not being charged is a burning red battery light! And in order to make sure of this, you can check the voltage of the battery. The battery terminals should have 12,5 ... 12,7 V. When the internal combustion engine is started, the voltage will rise to 13,5 ... 14,5 V. With the consumers turned on and the internal combustion engine running, the voltmeter readings usually jump from 13,8 to 14,3 ,14,6V. The absence of changes on the voltmeter display or when the indicator goes beyond XNUMXV indicates a breakdown of the generator.

When the generator is running, but not charging the battery, the reason may be hidden in the battery itself. Apparently it was completely discharged, which is called "zero", then the voltage is less than 11V. Zero charge can occur due to sulphated plates. If sulfation is insignificant, you can try to eliminate it. And try to charge with a starting-charger.

How to understand what the battery does not charge from the charger? When the battery is connected to the charger, the evidence that it is fully charged is the constantly changing voltage at the terminals and jumping voltage or current indicators on the device dial. If the charge does not go, then there will be no change. When there is no charge to the battery from the Orion type charger (having only indicators), it is very often possible to observe a buzz and a rare flashing of the “current” light bulb.

The car battery is not being charged by the generator. Why?

Common reasons when the battery does not charge from the generator are:

- Oxidation of the battery terminals;

- Stretched or broken alternator belt;

- Oxidation of wires on the generator or vehicle ground;

- Failure of diodes, voltage regulator or brushes;

- Sulfation of plates.

Because of what the battery may not be charged from the charger

the basic reasons due to which the car battery does not want to be charged not only from the generator but also from the charger can also be 5:

- Deep discharge of the battery;

- Closing one of the cans;

- Overcooling of the battery;

- Very high or low density of the electrolyte;

- Impurities in the electrolyte.

What can you do when your car battery is not charging?

The first step is to find out the cause, and only then take action to eliminate it. To do this, you need to measure the voltage at the battery terminals, check the level, density of the electrolyte and its color. it is also necessary to visually inspect the surface of the battery, auto wiring, and also to determine the current leakage without fail.

Let us consider in detail the possible consequences of each of the causes of poor battery performance, and also determine the actions that need to be performed in a given situation:

Contact terminal oxidation both prevents good contact and promotes leakage current. As a result, we get a fast discharge or an unstable / absent charge from the generator. There is only one way out - to check not only the condition of the battery terminals, but also on the generator and the vehicle weight. Strongly oxidized terminals can be removed by cleaning and lubricating oxides.

breakdown in the generator (belt, regulator, diodes).

Broken belt you would probably notice, but the fact is that even a slight loosening of the tension can contribute to slipping on the pulley (as well as oil). Therefore, when powerful consumers are turned on, the light on the panel may light up and the battery will be discharged, and on a cold internal combustion engine, a squeak is often heard from under the hood. You can fix this problem either by stretching or by replacing.

Diodes in the normal state, they should pass current only in one direction, checking with a multimeter will make it possible to identify the faulty one, although often they simply change the entire diode bridge. Incorrectly working diodes can cause both undercharging and overcharging of the battery.

When the diodes are normal, but they get very hot during operation, it means that the battery is being overcharged. Responsible for stress regulator... It is better to change it right away. In a situation where the battery is not fully charged, you need to pay attention to the generator brushes (after all, they wear out over time).

Deep discharge, as well as with a slight shedding of the active mass, when the battery does not want to be charged not only on the car from the generator, but even the charger does not see it, you can make a polarity reversal or give a high voltage so that it grabs the charge.

This procedure is often carried out with AVG batteries when there are less than 10 volts on its terminals. Polarity reversal allows you to start a fully discharged battery. But this will only help if the poles on the battery have really changed, otherwise you can only do harm.

Changing the battery poles (both lead-acid and calcium) occurs in the case of a complete discharge, when the voltage of some battery cans with a lower capacity than the rest, connected in series, decreases much faster than others. And having reached zero, as the discharge continues, the current for the lagging elements becomes charging, but it charges them in the opposite direction and then the positive pole becomes a minus, and the negative one becomes positive. Therefore, by changing, for a short time, the charger terminals, such a battery can be brought back to life.

But remember that if the pole change on the battery did not occur, then in the absence of protection from such a situation on the charger, the battery can be permanently damaged.

This process will fail if:

- the plates crumbled and the electrolyte became cloudy;

- one of the cans is closed;

- there is no required density of electrolyte in the battery.

Desulfation is well done by the polarity reversal method, but only no more than 80-90% of the capacity can be restored. The success of such a procedure lies in thick plates, thin ones are completely destroyed.

The density of the electrolyte is measured in g / cm³. Checked with a densimeter (hydrometer) at a temperature of + 25 ° C, should be 1,27 g / cm³. It is proportional to the concentration of the solution and inversely dependent on the ambient temperature.

Note that the density of the electrolyte in the battery must be the same in all sectors. And if in some of the cells it is greatly reduced, then this indicates the presence of defects in it (namely, a short circuit between the plates) or a deep discharge. But when such a situation is observed in all cells, then it is a deep discharge, sulfation, or simply obsolescence. A very high density is also not good - it means that the battery was boiling from overcharging due to the failure of the generator. Which also adversely affects the battery. To eliminate problems caused by uneven density, it is necessary to service the battery.

Features of maintenance of machine batteries

A set of instructions for the correct maintenance of different types of machine batteries. Features of servicing gel, alkaline and acid batteries Read more

With sulfation there is a deterioration or lack of contact of the electrolyte with the plates. Since plaque blocks access to the working fluid, then battery capacity drops dramatically, and recharging it does not give any result. The voltage either increases very slowly or does not change at all. Such the process is irreversible.

But sulfation at the initial stage can be overcome by a series of cycles of a full charge with a small current and a full discharge with a minimum current strength (for example, by connecting a 12V 5W light bulb). Or, the easiest way to restore is to pour a solution of soda, which is also capable of removing sulfates from the plates.

Closing one of the cans is a consequence of the collapsed plates and the appearance of sludge at the bottom of the battery. When trying to charge such a battery, there will be a strong bubbling of the electrolyte, as when fully charged. The defective section will boil but not recharge. There is nothing to help here.

Causes of breakdown of starter machine batteries

The service life of a 25% discharged battery is significantly reduced by:

- breakdown of the generator and voltage regulator;

- starter failures, leading to an increase in current strength or an increase in the number of attempts to start the internal combustion engine;

- oxidation of the terminals of the power wires;

- constant use of powerful consumers with long downtime in traffic jams;

- repeated crankshaft rotation with the starter on short trips.

A low electrolyte level during battery life is also a key reason for rapid battery failure. Therefore, the cause of the breakdown can be:

- Infrequent monitoring of the electrolyte level. In summer, the check should be done more often because the high temperature contributes to the rapid evaporation of water;

- Intensive use of the car (when the mileage is more than 60 thousand km per year). It requires checking the electrolyte level at least every 3-4 thousand km of run.

Graphical representation of the situation when the battery is not being charged. Infographics

To enlarge the image, just click on the picture.

Author: Ivan Matieshin