Malfunctions of the cylinder head VAZ 2106: how to identify them and fix them

Content

Malfunctions of the cylinder head of the VAZ "six" occur infrequently. However, when they appear with repairs, it is not worth delaying. Depending on the nature of the breakdown, it may be necessary not only to constantly top up oil or coolant, but also reduce the engine resource.

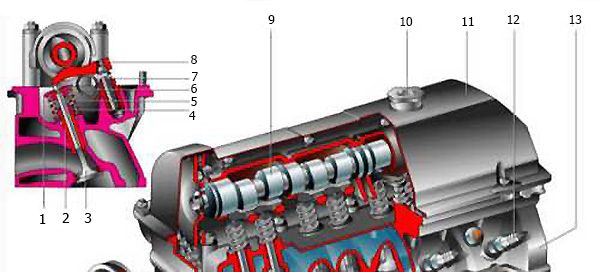

Description of the cylinder head VAZ 2106

The cylinder head (cylinder head) is an integral part of any internal combustion power unit. Through this mechanism, the supply of the combustible mixture to the cylinders and the removal of exhaust gases from them are controlled. The node has inherent malfunctions, the detection and elimination of which is worth dwelling on in more detail.

Purpose and principle of operation

The main purpose of the cylinder head is to ensure the tightness of the cylinder block, that is, to create a sufficient obstacle to the escape of gases to the outside. In addition, the block head solves a whole range of tasks that ensure the operation of the engine:

- forms closed combustion chambers;

- participates in the work of the State Russian Museum;

- involved in the lubrication and cooling system of the motor. For this, there are corresponding channels in the head;

- participates in the operation of the ignition system, since the spark plugs are located in the cylinder head.

For all of these systems, the head of the block is a body element that ensures the rigidity and integrity of the design of the power unit. If malfunctions occur with the cylinder head, the normal operation of the engine is disrupted. Depending on the nature of the breakdown, there may be problems with both the ignition system, lubrication, and the cooling system, which requires prompt repair.

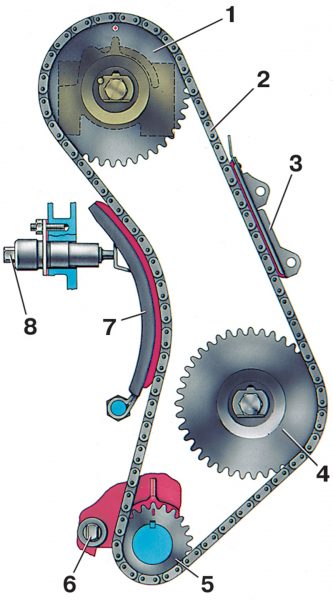

The principle of operation of the cylinder head is reduced to the following steps:

- The camshaft is driven from the engine crankshaft by means of the timing chain and sprocket.

- The camshaft cams act on the rockers at the right time, opening and closing the cylinder head valves at the right time, filling the cylinders with the working mixture through the intake manifold and releasing exhaust gases through the exhaust.

- The operation of the valves occurs in a certain sequence, depending on the position of the piston (inlet, compression, stroke, exhaust).

- Coordinated work of the chain drive is provided by the tensioner and damper.

What it consists of

The cylinder head of the "six" is an 8-valve and consists of the following structural parts:

- head gasket;

- timing mechanism;

- cylinder head housing;

- chain drive;

- the combustion chamber;

- tension device;

- candle holes;

- planes for mounting the intake and exhaust manifolds.

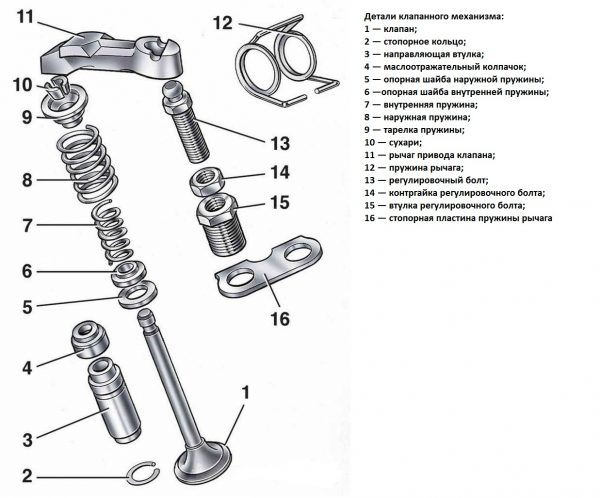

The node in question is common to four cylinders. Cast iron seats and valve bushings are installed in the body. The seat edges are machined after they are installed in the body to ensure a perfect fit for the valves. The holes in the bushings are also machined after being pressed into the cylinder head. This is necessary so that the diameter of the holes in relation to the working planes of the saddles is accurate. The bushings have helical grooves for valve stem lubrication. Valve seals are located on top of the bushings, which are made of special rubber and a steel ring. The cuffs fit tightly on the valve stem and prevent lubricant from entering the combustion chamber through the gaps between the bushing wall and the valve stem. Each valve is equipped with two coil springs, which are supported by special washers. On top of the springs there is a plate holding two crackers on the valve stem, having the shape of a truncated cone.

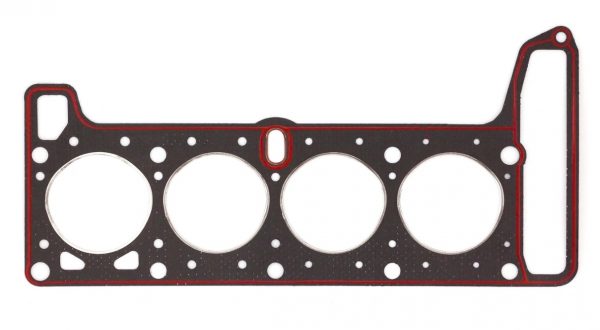

Cylinder head gasket

The head gasket ensures that the cylinder head fits snugly against the cylinder block. The material for the manufacture of the seal is reinforced asbestos, which is able to withstand the high temperatures that occur during the operation of the power unit. In addition, reinforced asbestos withstands high pressure under different engine loads.

Timing mechanism

The gas distribution device consists of a valve mechanism and a chain drive. The first of them is responsible for the operation of the valves and consists of directly inlet and outlet elements, springs, levers, seals, bushings and a camshaft. The design of the second includes a double-row chain, an asterisk, a damper, a tension device and a shoe.

cylinder head housing

The block head is made of aluminum alloys and is fixed to the cylinder block through a gasket using ten bolts, which are tightened in a certain order and with a given force. On the left side of the cylinder head, candle wells are made into which spark plugs are screwed. On the right side, the housing has channels and planes, to which the manifolds of the intake and exhaust systems adjoin through the seal. From above, the head is closed with a valve cover, which prevents oil from leaking out of the motor. A tensioner and a timing mechanism drive are mounted in front.

Malfunctions when removal and installation of the cylinder head is required

There are a number of malfunctions, due to which the cylinder head of the VAZ "six" has to be dismantled from the car for further diagnostics or repair. Let's dwell on them in more detail.

Burnt out gasket

The following signs indicate that the cylinder head gasket has failed (burned out or pierced it):

- the appearance of smudges or gas breakthrough at the junction between the engine block and the head. With this phenomenon, extraneous noise appears in the operation of the power plant. If the outer shell of the seal breaks, traces of grease or coolant (coolant) may appear;

- the formation of an emulsion in engine oil. This happens when the coolant enters the oil through the gasket or when a crack forms in the BC;

The formation of an emulsion indicates the ingress of coolant into the oil

The formation of an emulsion indicates the ingress of coolant into the oil - white smoke from the exhaust system. White exhaust occurs when coolant enters the combustion chamber of the engine. In such a situation, the liquid level in the expansion tank gradually decreases. Untimely repairs can lead to water hammer. Water hammer - a malfunction that is caused by a sharp increase in pressure in the under-piston space;

If the gasket is damaged and coolant enters the cylinders, thick white smoke will come out of the exhaust pipe.

If the gasket is damaged and coolant enters the cylinders, thick white smoke will come out of the exhaust pipe. - lubricant and / or exhaust gases entering the engine cooling system. You can identify the ingress of lubricant into the coolant by the presence of oil stains on the surface of the liquid in the expansion tank. In addition, when the tightness of the gasket is broken, bubbles may appear in the tank, indicating the penetration of exhaust gases into the cooling system.

The appearance of air bubbles in the expansion tank indicates the ingress of exhaust gases into the cooling system

The appearance of air bubbles in the expansion tank indicates the ingress of exhaust gases into the cooling system

Video: cylinder head gasket damage

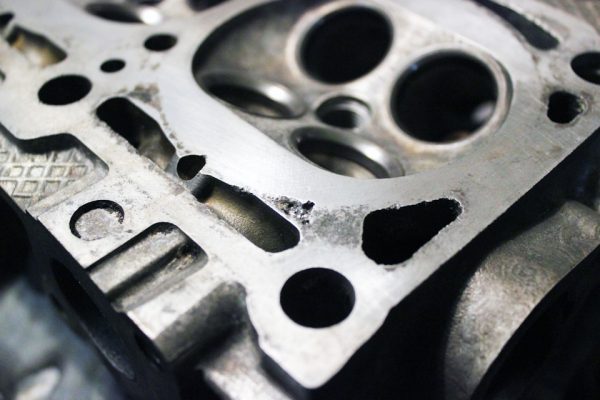

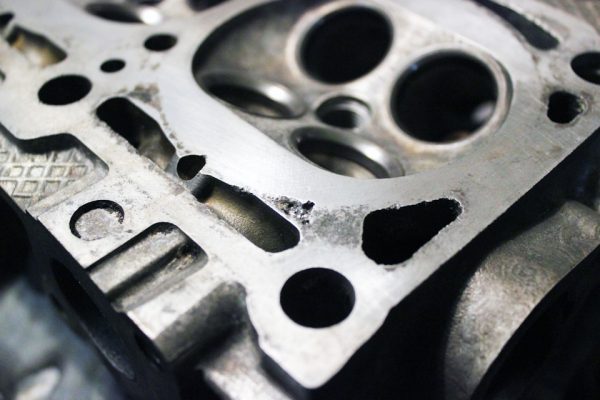

Damage to the mating plane of the cylinder head

The following reasons can lead to the formation of defects in the mating surface of the block head:

- long-term operation of the power unit;

- motor overheating;

- poor quality coolant.

Defects of this kind are eliminated by processing the plane, with the preliminary dismantling of the head.

Cracks in the block head

The main reasons that lead to the appearance of cracks in the cylinder head are overheating of the motor, as well as improper tightening of the mounting bolts during installation. Depending on the nature of the damage, the head can be repaired using argon welding. In case of serious defects, the cylinder head will have to be replaced.

Guide bushing wear

With a high engine mileage or the use of low-quality engine oil, the valve guides wear out, which leads to a leak between the valve seat and the valve disc. The main symptom of such a malfunction is increased oil consumption, as well as the appearance of blue smoke from the exhaust pipe. The problem is fixed by replacing the guide bushings.

Valve seat wear

Valve seats can wear for several reasons:

- use of low-quality fuel;

- high engine mileage;

- incorrect ignition setting.

The malfunction is solved by editing or replacing the saddles. In addition, the ignition system must be checked.

Broken spark plug

Quite rarely, but it happens that as a result of excessive tightening of the candle, the part breaks off on the thread in the candle hole. To remove the remnants of the cylinder head candle element, it is required to dismantle and unscrew the threaded part with improvised tools.

CPG malfunctions

In case of malfunctions of the cylinder-piston group of the engine, the block head also has to be removed. The most common breakdowns of the CPG include:

- increased wear of cylinders, rings and pistons;

- piston damage;

- placement of rings.

With excessive wear of the cylinders, the engine is completely disassembled to replace the piston group, as well as to bore the inner cavity of the cylinders on the machine. As for the damage to the pistons themselves, they burn out, although infrequently. All this leads to the need to dismantle the cylinder head and replace faulty parts. When the rings lie, the normal operation of the cylinder and the engine as a whole becomes impossible.

Ring Stuck - The rings are stuck in the piston grooves due to the accumulation of combustion products in them. As a result, compression and power are reduced, oil consumption is increased and uneven cylinder wear occurs.

Cylinder head repair

If there are problems with the Zhiguli cylinder head of the sixth model that require the assembly to be removed from the car, then repair work can be carried out in a garage by preparing the appropriate tools and components.

Head removal

To remove the cylinder head, you will need the following tool:

- a wrench with an extension;

- a set of keys;

- ratchet handles;

- heads for 13 and 19.

The sequence of actions for dismantling the node is as follows:

- Drain the coolant from the cooling system.

- We remove the air filter with the housing, the carburetor, the valve cover, disconnect the intake and exhaust manifolds, moving the latter to the side along with the "pants".

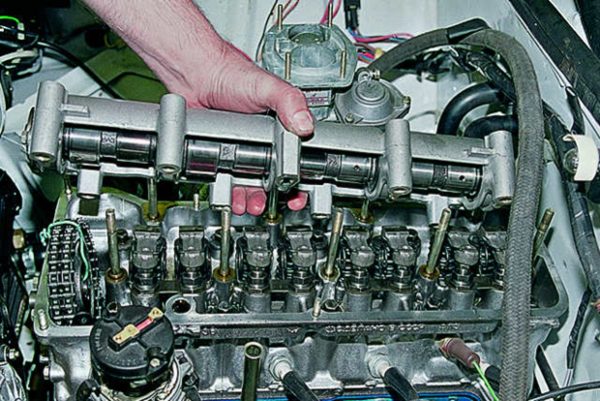

- We unscrew the mount and remove the sprocket from the camshaft, and then the camshaft itself from the cylinder head.

We unscrew the fasteners and remove the camshaft from the block head

We unscrew the fasteners and remove the camshaft from the block head - We loosen the clamp and tighten the coolant supply hose to the heater.

We loosen the clamp and tighten the coolant supply hose to the stove

We loosen the clamp and tighten the coolant supply hose to the stove - Similarly, remove the pipes going to the thermostat and radiator.

We remove the pipes going to the radiator and thermostat

We remove the pipes going to the radiator and thermostat - Remove the terminal from the temperature sensor.

Remove the terminal from the temperature sensor

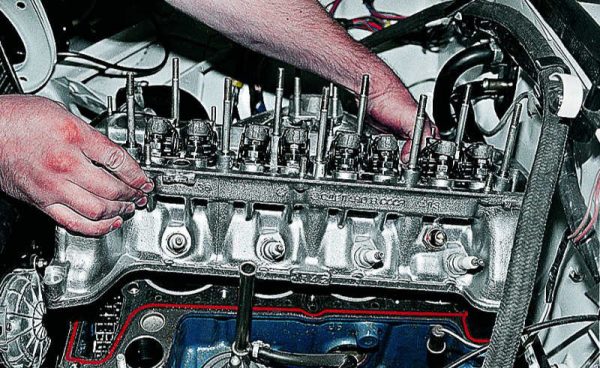

Remove the terminal from the temperature sensor - With a head for 13 and 19 with a knob and an extension, we unscrew the bolts securing the cylinder head to the block.

We turn off the fastening of the head of the block with a wrench with a head

We turn off the fastening of the head of the block with a wrench with a head - Raise the mechanism and remove it from the motor.

Unscrewing the fasteners, remove the cylinder head from the cylinder block

Unscrewing the fasteners, remove the cylinder head from the cylinder block

Disassembly of the block head

Complete cylinder head disassembly is required for repairs such as replacement of valves, valve guides or valve seats.

If the valve seals are out of order, then there is no need to remove the cylinder head - the lip seals can be replaced by removing only the camshaft and drying the valves.

Of the tools you will need:

- key for 17 and 21;

- desiccant;

- oil seal remover;

- tweezers;

- tin solder bar d = 8 mm;

- a hammer;

- long nose pliers or magnetic handle.

We disassemble the node in this order:

- We dismantle the rockers along with the locking springs.

Remove rockers and springs from the cylinder head

Remove rockers and springs from the cylinder head - With a cracker, we compress the springs of the first valve and take out crackers with long-nose pliers.

Compress the springs with a dryer and remove the crackers

Compress the springs with a dryer and remove the crackers - Remove the valve plate and springs.

We dismantle the plate and springs from the valve

We dismantle the plate and springs from the valve - With a puller we tighten the oil scraper cap.

The oil scraper cap is removed from the valve stem using a screwdriver or puller

The oil scraper cap is removed from the valve stem using a screwdriver or puller - We take out the valve from the guide sleeve.

The valve is removed from the guide sleeve

The valve is removed from the guide sleeve - We carry out a similar procedure with the rest of the valves.

- Loosen and remove the adjusting screw.

Loosen and remove the adjustment screw

Loosen and remove the adjustment screw - We unscrew the bushings of the adjusting screws with a key of 21.

Using a 21 wrench, unscrew the bushings of the adjusting screws

Using a 21 wrench, unscrew the bushings of the adjusting screws - Dismantle the lock plate.

Unscrew the mount, remove the locking plate

Unscrew the mount, remove the locking plate - After completing the repair procedure, we assemble the cylinder head in the reverse order.

Lapping valves

When replacing valves or seats, the elements must be lapped together to ensure tightness. For work you will need:

- diamond paste;

- electric drill with adjustable speed.

We grind the valves as follows:

- Apply lapping paste to the valve plate.

Abrasive paste is applied to the lapping surface

Abrasive paste is applied to the lapping surface - We insert the valve into the guide sleeve and clamp the stem into the chuck of the electric drill.

- We turn on the drill at low speeds, press the valve to the seat and rotate it first in one direction, then in the other direction.

The valve with the stem clamped into the drill chuck is lapped at low speed

The valve with the stem clamped into the drill chuck is lapped at low speed - We grind the part until an even matte mark appears on the seat and chamfer of the valve disc.

After lapping, the working surface of the valve and the seat should become dull

After lapping, the working surface of the valve and the seat should become dull - We wash the valves and saddles with kerosene, put them in place, replacing the seals.

Saddle replacement

To replace the seat, it will need to be dismantled from the cylinder head. Since there is no special equipment for these purposes in garage conditions, welding or improvised tools are used for repairs. To dismantle the seat, the old valve is welded to it, after which it is knocked out with a hammer. A new part is installed in the following sequence:

- We heat the cylinder head to 100 ° C, and cool the saddles in the freezer for two days.

- With a suitable guide, we drive the parts into the head housing.

The new saddle is mounted with a suitable adapter

The new saddle is mounted with a suitable adapter - After cooling the cylinder head, countersink the saddles.

- Chamfers are cut with cutters with different angles.

To cut the chamfer on the valve seat, cutters with different angles are used.

To cut the chamfer on the valve seat, cutters with different angles are used.

Video: cylinder head valve seat replacement

Replacing bushings

Valve guides are replaced with the following set of tools:

- a hammer;

- mandrel for knocking out and pressing bushings;

- reamer 8.025 mm;

- open end wrench.

The bushing replacement process consists of the following steps:

- We knock out the old bushing with a hammer and a suitable adapter.

Old bushings are pressed out with a mandrel and a hammer

Old bushings are pressed out with a mandrel and a hammer - Before installing new parts, place them in the refrigerator for 24 hours, and heat the block head in water at a temperature of +60˚С. We hammer the sleeve with a hammer until it stops, after putting on the stopper.

The new bushing is inserted into the seat and pressed in with a hammer and mandrel.

The new bushing is inserted into the seat and pressed in with a hammer and mandrel. - Using a reamer, make holes according to the diameter of the valve stem.

Having installed the guide bushings in the head, it is necessary to fit them using a reamer

Having installed the guide bushings in the head, it is necessary to fit them using a reamer

Video: replacing valve guides

Watch this video on YouTube

Installation of the cylinder head

When the repair of the head of the block is completed or the gasket is replaced, the mechanism must be reinstalled. The cylinder head is mounted using the following tools:

- heads 13, 17, 19;

- a wrench with an extension;

- torque wrench.

The installation procedure is as follows:

- We wipe the surface of the cylinder head and block with a clean rag.

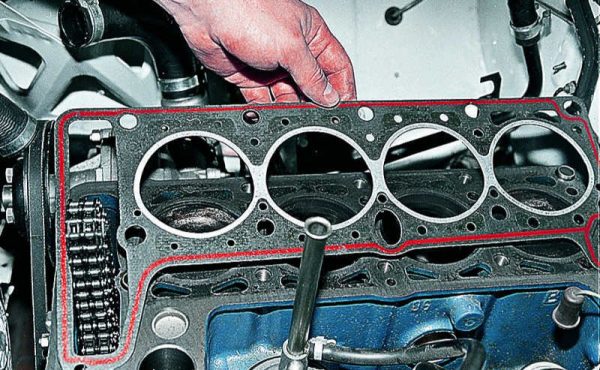

- We place a new gasket on the cylinder block.

The new cylinder head gasket is installed in reverse order.

The new cylinder head gasket is installed in reverse order. - We make the alignment of the seal and the head of the block using two bushings.

There are two bushings on the cylinder block for centering the gasket and the cylinder head.

There are two bushings on the cylinder block for centering the gasket and the cylinder head. - We tighten the bolts No. 1–10 with a torque wrench with a force of 33,3–41,16 N.m, and then finally tighten it with a moment of 95,9–118,3 N.m. Lastly, we wrap bolt No. 11 near the distributor with a force of 30,6–39 N.m.

- We tighten the bolts in a certain sequence, as shown in the photo.

The cylinder head is tightened in a certain sequence

The cylinder head is tightened in a certain sequence - Further assembly of the cylinder head is carried out in the reverse order of dismantling.

Video: tightening the cylinder head on the "classic"

Watch this video on YouTube

Rejection of cylinder head bolts

It is recommended to change the bolts holding the head of the block with each dismantling of the assembly. However, this is done quite rarely and is limited to the usual inspection of the thread. If it is in order, then the bolts are reused. It should be borne in mind that the new bolt has a size of 12 * 120 mm. If the length is significantly different or the fasteners are difficult to screw into the cylinder block when trying to screw it in, then this may indicate stretching and the need to replace the bolt. When tightening the cylinder head with a deliberately stretched bolt, there is a possibility of its breakage.

If, during the installation of the block head, the stretched bolt does not break, then this is not a guarantee that it will provide the necessary tightening force during the operation of the vehicle. After some time, the cylinder head tightening may loosen, which will lead to a breakdown of the gasket.

If there are malfunctions with the VAZ 2106 cylinder head, as a result of which the normal operation of the power unit is disrupted, you can fix the problem yourself without visiting a car service. To do this, you need to prepare the appropriate tool, read and follow the step-by-step instructions.