New week and new battery: LeydenJar has silicon anodes and 170 percent batteries. is present

Content

The Dutch company LeydenJar (Polish Leyden bottle) boasted of creating a production-ready silicon anode for lithium-ion cells. This allows the cell capacity to be increased by 70 percent compared to standard solutions with graphite anodes.

Silicon instead of graphite in anodes is a nice advantage but a difficult factor.

Table of contents

- Silicon instead of graphite in anodes is a nice advantage but a difficult factor.

- LeydenJar: And we stabilized the silicon, ha!

- The stamina problem remains

Silicon and carbon belong to the same group of elements: carbonaceous elements. Carbon in the form of graphite is used in the anodes of lithium-ion cells, but a way has long been sought to replace it with a cheaper and more promising element - silicon. Silicon atoms form a more loose and porous structure. And the more porous the structure, the greater the ratio of surface to volume, the more places where lithium ions can be fixed.

More space for lithium ions means more anode capacity. That is, a larger battery capacity, which uses such an anode.

Theoretical calculations show that a silicon anode can store ten times (10 times!) more lithium ions than a graphite anode... However, this comes at a cost: while graphite anodes expand slightly during charging, a charged silicon anode can swell up to three times (300 percent)!

The effect? The material crumbles, the link quickly loses its capacity. In short: it can be thrown away.

LeydenJar: And we stabilized the silicon, ha!

Over the past ten or so years, it has become possible to partially supplement the graphite with silicon to recover at least a few percent of the additional power. Such systems were stabilized by various nanostructures so that the effect of the growth of silicon networks did not damage cells. LeydenJar claims to have developed a method of using anodes made entirely of silicon.

The company has tested silicon anodes in commercially available kits, for example with NMC 622 cathodes. specific energy 1,35 kWh / lwhile the 2170 cells used in the Tesla Model 3 / Y offer around 0,71 kWh / L. LeydenJar says the energy density is 70 percent higher, which means a battery of a certain size can store 70 percent more energy.

We translate this to the Tesla Model 3 Long Range: instead of the actual 450 kilometers, the flight range could reach 765 kilometers on a single charge.... No battery increase.

The stamina problem remains

Unfortunately, LeydenJar silicon based cells are not ideal. They were able to survive more than 100 working cycles в charging / discharging with a capacity of 0,5C... The industry standard is at least 500 cycles, and at 0,5 ° C, even not very complex lithium-ion cells have to withstand 800 or more cycles. Therefore, the company is working to increase the life of the cells.

> Samsung SDI with lithium-ion battery: today graphite, soon silicon, soon lithium metal cells and a range of 360-420 km in the BMW i3

Note from the editors of www.elektrowoz.pl: When we talk about silicon and graphite in lithium-ion cells, we are talking about anodes. On the other hand, when we mention NMC, NCA or LFP, sometimes using the phrase "cell chemistry", we mean cathodes. The cell is an anode, cathode, electrolyte and some other elements. Each of them affects the parameters.

Note 2 from www.elektrowoz.pl edition: The swelling process of silicon anodes should not be confused with the swelling of the cells in bags. The latter swell due to the gas released inside, which does not have the ability to escape from the inside.

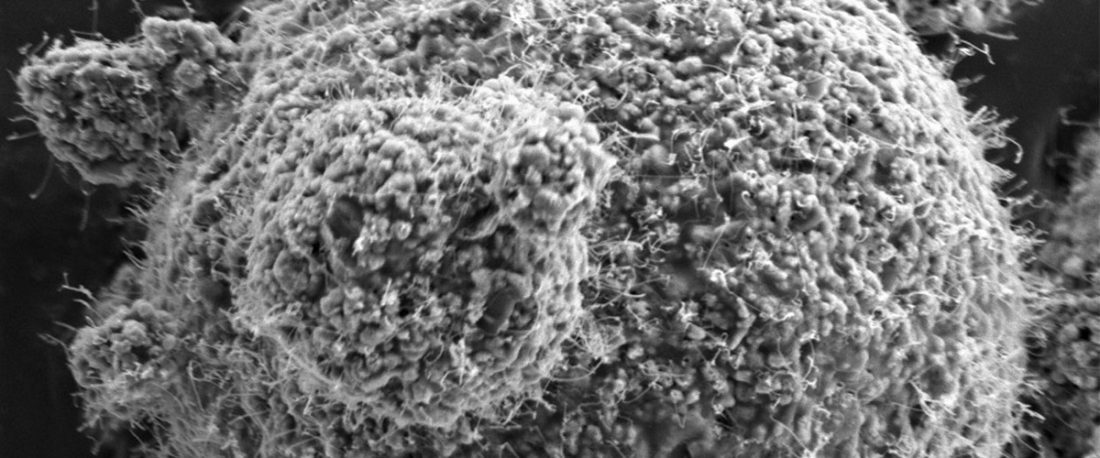

Opening photo: punching something 😉 (c) LeydenJar. Given the context, we are probably referring to the silicon anode. However, if we pay attention to the softness of the material (it bends, it can be cut with a scalpel), then we are dealing with some silicones, silicon-based polymers. Which is intriguing in itself.

This may interest you: