About the crankshaft sensor VAZ 2107

Content

The operation of the injection engine directly depends on such a part as the crankshaft sensor. It serves to ensure the synchronous operation of the injectors with the ignition system, therefore its other name is the ignition advance sensor. On the VAZ 2107, the injector crankshaft sensor may fail over time.

Crankshaft sensor on the VAZ 2107 - design and principle of operation

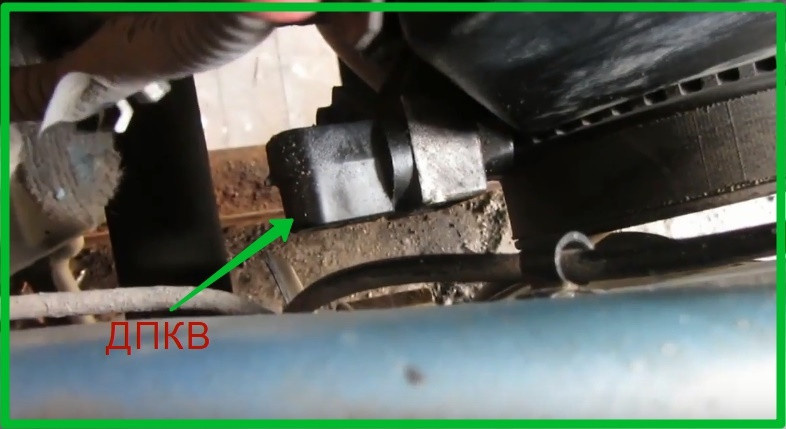

The crankshaft position sensor or DPKV on the VAZ 2107 ensures the operation of the engine (not stable, but in general). With it, the ECU knows what position the crankshaft is in. From here, the control unit knows the location of the pistons in the cylinders, which directly affects the injection of fuel through the nozzles and the occurrence of a spark to ignite the fuel assemblies.

The considered device has a simple design. The sensors installed in all seven operate on the principle of inductance. The part consists of a cylindrical metal base, on the surface of which a wire (coil) is wound. The top of the coil is covered with a permanent magnet. The operation of the device is associated with a ring gear, which is attached to the crankshaft. It is with the help of this ring gear that the sensor picks up the signals and transmits them to the computer. The principle of operation of the device is as follows: when the crown tooth is at the level of the steel core of the DPKV, an electromotive force is induced in the winding. A voltage appears at the ends of the winding, which is set by the ECU.

The sprocket has 58 teeth. Two teeth have been removed from the wheel, which is required to determine the initial position of the crankshaft. If the DPKV fails, which is extremely rare, then starting the engine and running it is simply impossible. The brand of the sensor, which is installed on the VAZ 2107, has the following form: 2112-3847010-03/04.

Signs of a broken sensor

The main sign of a DPKV breakdown is the inability to start the engine. Such a failure occurs due to a complete malfunction of the device. If the surface of the DPKV is contaminated or the contacts are oxidized, the following malfunctions can be detected:

- Deterioration of vehicle dynamics: weak acceleration, power loss, jerks when shifting gears.

- Turnovers begin to float, and not only at idle, but also while driving.

- Increase fuel consumption. If the ECU receives a distorted signal, this negatively affects the operation of the injectors.

- The appearance of knocks in the engine.

If the above symptoms are found, then DPKV should be checked. To do this, you need to know where the crankshaft sensor is located. On the VAZ 2107, the DPKV is located on the front cover of the engine, where it is mounted on a bracket. On other car models, this element may be located on the other side of the crankshaft near the flywheel. If you suspect a malfunction of the DPKV, you should check it.

Ways to check DPKV

You can check the adequacy of the crankshaft sensor on all seven in three different ways. To begin with, it should immediately be noted that the malfunction of the device can be determined visually. To do this, inspect the part, and in the presence of contamination, as well as microcracks in the magnet housing, one can judge its failure. Pollution is easily removed, but in the presence of microcracks, the part has to be changed.

The crankshaft sensor on the VAZ 2107 injector is checked in three ways:

- Resistance check. The multimeter is set to resistance measurement mode. The probes touch the terminals of the device. If the device shows a value from 550 to 750 ohms, then the element is suitable for use. If the value is higher or lower than normal, then the part must be replaced.

- Checking the inductance. Connect the LED or multimeter leads to the terminals of the device. At the same time, set the device to the DC voltage measurement mode. Bring a metal object to the end of the piece and quickly remove it. In this case, an increase in voltage should occur (the LED will light up). This indicates that the DPKV is working.

- Oscilloscope check. The most accurate and reliable way to test with an oscilloscope. To do this, the DPKV is connected to the device, and then a metal part must be brought to it. The circuit determines the correct operation of the DPKV.

The inductive crankshaft position sensor used on the seven creates sinusoidal pulses. They enter the computer, where they are rectified into rectangular pulses. Based on these pulses, the control unit decides to apply a pulse to the injectors and spark plugs at the right time. If during the test it turned out that the DPKV is faulty, it must be replaced.

How to replace the crankshaft sensor on the seven

Knowing where the DPKV is located on the VAZ 2107, it will not be difficult to disassemble the device. This procedure is not difficult and does not take much time. Detailed instructions on how to replace the crankshaft sensor on a VAZ 2107 look like this:

- Work is carried out under the hood of the car, but it can also be done from below.

- Disconnect the cable tie from the DPKV.

- Using a Phillips screwdriver, unscrew the clip that secures the sensor.

- Remove the device and install a new one in its place. Assembly is carried out in the reverse order of disassembly.

After replacing the device, you can check the performance of the engine. Although the part rarely fails, it is recommended to always have a spare sensor in the machine. If an element fails, it can always be quickly replaced to keep moving.

As a result, it should be noted that DPKV is the most important sensor. It has a simple design and rarely fails. The estimated cost of the device for all seven is about 1000 rubles. It is recommended to check the part not only at the first signs of a malfunction, but also periodically clean the working surface from contamination.