Do-it-yourself lambda probe snag

Content

After the destruction or removal of the catalyst or the failure of the oxygen sensor (lambda probe), the internal combustion engine operates in a non-optimal mode due to incorrect correction of the air-fuel mixture, and the Check Engine indicator lights up on the instrument panel. Various ways to deceive the electronic control unit allow to solve this problem.

If the oxygen sensor is working, a mechanical snag lambda probe will help, if it fails, you can use the electronic one. Read below to learn how to pick up a snag of a lambda probe or make it yourself.

How the lambda probe snag works

Lambda probe snag - a device that provides the transmission to the computer of the optimal oxygen content in the exhaust gases, if the real parameters do not correspond to them. This problem is solved by correcting the readings of the existing gas analyzer or its signal. The best option selected depending on the environmental class and car model.

There are two types of cheats:

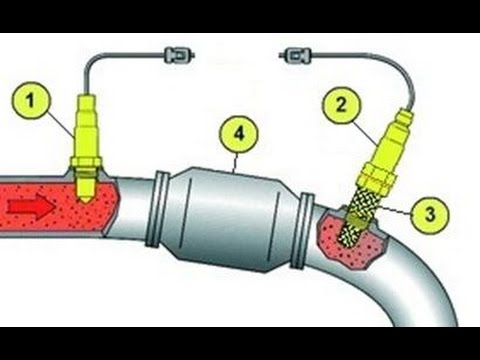

- Mechanical (sleeve-screw or mini-catalyst). The principle of operation is based on creating a barrier between the oxygen sensor and gases in the exhaust system.

- Electronic (resistor with capacitor or separate controller). The emulator is placed in a wiring gap or instead of a regular DC. The principle of operation of an electronic lambda probe snag is to simulate the correct sensor readings.

The screw-in sleeve (dummy) allows you to successfully deceive the ECU of old cars that meet the environmental class of at least Euro-3, and the mini-catalyst is suitable even for modern cars with standards up to Euro-6. In both cases, a serviceable DC is required, which is screwed into the snag body. so the working part of the sensor is surrounded by relatively pure gases and transmits normal data to the computer.

Lambda probe snag - mini-catalyst (catalyst grid visible)

Factory custom lambda probe emulator on a microcontroller

For an electronic blende based on a resistor and a capacitor, it is not the environmental class that is important, but the principle of operation of the computer. For example, this option does not work on the Audi A4 - the computer will generate an error due to incorrect data. In addition, it is not always possible to choose the optimal parameters of electronic components. An electronic snag with a microcontroller independently simulates the operation of an oxygen sensor, even if it is absent and completely inoperable.

There are two types of independent electronic tricks with a microcontroller:

- independent, generating a signal for the normal operation of the lambda;

- corrective readings according to the first sensor.

The first type of emulators is usually used on cars with LPG of old generations (up to 3), where when driving on gas, it is important to create the appearance of normal operation of the oxygen sensor. The second ones are installed after cutting out the catalyst instead of the second lambda and imitate its normal operation according to the readings of the first sensor.

How to make your own lambda probe snag

Do-it-yourself lambda probe snag: spacer manufacturing video

If you have the right tool, you can make the lambda probe snag yourself. The easiest to manufacture is a mechanical sleeve and an electronic simulator with a resistor and a capacitor.

To make a pacifier you need:

- metal lathe;

- a small blank of bronze or stainless steel (length about 60–100 mm, thickness about 30–50 mm);

- cutters (cutting, boring and thread-cutting) or cutters ?, tap and die.

To make an electronic blende of a lambda probe, you will need:

Making an electronic blende of an oxygen sensor with your own hands: video

- capacitors 1–5 uF;

- resistors 100 kOhm - 1 mOhm and / or trimmer with such a range;

- soldering iron;

- solder and flux;

- insulation;

- case box;

- sealant or epoxy.

Turning a screw and making a simple electronic blende, with the appropriate skills (turning / soldering electronics), will take no more than an hour. With the other two options it will be more difficult.

further it will be told how to make a snag of a lambda probe after removing the catalyst, so that Check Engine errors with codes P0130-P0179 (related to lambda), P0420-P0424 and P0430-P0434 (catalyst errors) do not occur.

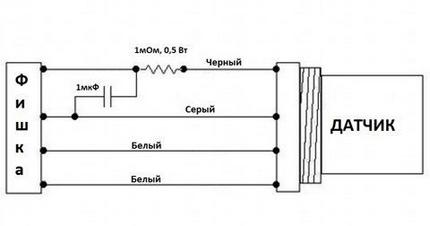

Electronic blende circuit

The electronic snag of the lambda probe works on the principle of distorting the real sensor signal to the one that is needed for the normal operation of the motor. There are two system options:

- With resistor and capacitor. A simple circuit that allows you to change the shape of an electrical signal from a DC by soldering in additional elements. The resistor serves to limit the voltage and current, and the capacitor serves to eliminate voltage ripple on the load. This type of blende is usually used after the catalyst has been cut out to simulate its presence.

- With microcontroller. An electronic snag of a lambda probe with its own processor is capable of generating a signal that simulates the readings of a working oxygen sensor. There are dependent emulators that are tied to the first (upper) DC, and independent emulators that generate a signal without external instructions.

The first type is used to deceive the ECU after the removal or failure of the catalyst. The second one can also serve for these purposes, but more often it is used as a snag of the first lambda probe for normal driving with old generation HBO.

Scheme of the electronic blende of the oxygen sensor

The electronic snag of the lambda probe, the circuit of which is presented above, consists of only two elements and is easy to manufacture, but may require the selection of radio components at face value.

Integration of resistor and capacitor in wiring

Electronic blende of a lambda probe on a resistor with a capacitor

The resistor and capacitor can be integrated into a car with two oxygen sensors with an environmental class Euro-3 and higher. Do-it-yourself electronic snag of a lambda probe is done like this:

- the resistor is soldered into the break of the signal wire;

- a non-polar capacitor is connected between the signal wire and ground, after the resistor, on the side of the sensor connector.

The principle of operation of the simulator is simple: the resistance in the signal circuit reduces the current coming from the second oxygen sensor, and the capacitor smooths out its pulsations. As a result, the injector ECU "thinks" that the catalyst is functioning and the oxygen content in the exhaust is within the normal range.

Do-it-yourself lambda probe snag scheme

To obtain the correct signal (pulse shape), you need to select the following details:

- non-polar film capacitor from 1 to 5 microfarads;

- resistor from 100 kΩ to 1 MΩ with a power dissipation of 0,25–1 W.

To simplify, you can first use a tuning resistor with this range, in order to find a suitable resistance value. The most common circuit is with a 1 MΩ resistor and a 1 uF capacitor.

You need to connect the snag to the break in the sensor wiring harness, while preferably away from hot exhaust elements. in order to protect radio components from moisture and dirt, it is better to place them in a case and fill them with sealant or epoxy.

Microprocessor board in the lambda probe wiring break

An electronic snag of a lambda probe on a microcontroller is needed in two cases:

- substitution of the readings of the first (or only) oxygen sensor when driving on HBO 2 or 3 generations;

- substitution of the readings of the second lambda for a car with Euro-3 and higher without a catalyst.

You can assemble an oxygen sensor emulator on a do-it-yourself microcontroller for HBO using the following set of radio components:

- integrated circuit NE555 (master controller that generates pulses);

- capacitors 0,1; 22 and 47 uF;

- resistors for 1; 2,2; 10, 22 and 100 kOhm;

- Light-emitting diode;

- relay.

Do-it-yourself electronic snag of a lambda probe - a diagram for HBO

The blende described above is connected through a relay into the cut of the signal wire between the oxygen sensor and the computer. When operating on gas, the relay includes an emulator in the circuit that generates fake oxygen sensor signals. When switching to gasoline, the oxygen sensor is connected directly to the computer using a relay. in this way, both the normal functioning of the lambda on gasoline and the absence of errors on gas are achieved at the same time.

If you buy a ready-made emulator of the first lambda probe for HBO, it will cost about 500–1000 rubles.

It is also possible to produce an electronic snag of a lambda probe to simulate the readings of the second sensor with your own hands. For this you will need:

- resistors for 10 and 100 ohms (2 pcs.), 1; 6,8; 39 and 300 kOhm;

- capacitors for 4,7 and 10 pF;

- amplifiers LM358 (2 pcs.);

- Schottky diode 10BQ040.

The electrical circuit of the specified emulator is shown in the image. The principle of operation of the snag is to change the output readings of the first oxygen sensor and transfer them to the computer under the guise of readings from the second one.

Scheme of a simple electronic emulator of the second lambda probe

The above scheme is universal, it allows you to simulate the operation of both titanium and zirconium oxygen sensors.

A ready-made emulator of the second lambda probe based on a microcontroller will cost from 1 to 5 thousand rubles, depending on the complexity.

Drawing of a mechanical snag

Drawing of a mechanical blende of a lambda probe for many zirconium sensors for Euro-3: click to enlarge

A mechanical snag of a lambda probe can be used on a car with a remote catalyst and a working second (lower) oxygen sensor. A dummy screw with a hole works normally on Euro 3 and lower class machines, the sensors of which are not very sensitive. The mechanical blende of the lambda probe, the drawing of which is shown in the illustration, belongs to this type.

For Euro-4 and above, you need a snag with a miniature catalytic converter inside. It will purify the gases in the sensor zone, thereby simulating the operation of the missing standard catalyst. It is more difficult to make such a snag of a lambda probe with your own hands, since it also needs a catalytic agent.

Sleeve with mini catalytic converter

To make a mechanical snag of a lambda probe with your own hands, you will need a lathe and the ability to work with it, as well as:

- a blank of bronze or heat-resistant stainless steel about 100 mm long and 30–50 mm in diameter;

- cutters (cutting, boring and thread-cutting);

- tap and die M18x1,5 (instead of cutters for threading);

- catalytic element.

The main difficulty is the search for a catalytic element. The easiest way is to cut it out of the broken catalyst filler by selecting a relatively whole section of it.

Do-it-yourself lambda probe trick with a mini-catalyst: spacer drawing: click to enlarge

The oxidation of carbon monoxide and unburned hydrocarbons in the catalyst is provided not by the ceramic itself, but by the deposition of noble metals (platinum, rhodium, palladium) deposited on it. Therefore, conventional ceramic filler is useless - it serves only as an insulator that reduces the flow of gases to the sensor, which does not give the desired effect.

In a mechanical blende of the second lambda probe, you can use the remnants of an already collapsed catalytic converter with your own hands, so do not rush to hand it over to buyers.

A factory mechanical blende of a lambda probe with a mini-catalyst costs 1-2 thousand rubles.

Screwdriver with small diameter hole

The lambda probe snag screw is made in the same way as the mini-catalyst. For this you need:

- lathe;

- a blank made of bronze or heat-resistant stainless steel;

- set of cutters and/or tap and plate M18x1,5.

Do-it-yourself mechanical blende of a lambda probe: screw drawing

The only difference in design is that there is no catalytic filler inside, and the hole in the lower part has a smaller (2–3 mm) diameter. It limits the flow of exhaust gases to the oxygen sensor, thereby providing the desired reading.

How long does a snag lambda probe last

Mechanical oxygen sensor snags without a catalytic filler are the simplest and most durable, but not very effective. They work without problems on Euro-3 environmental class engines equipped with low-sensitivity lambda probes. How long a snag of this type of lambda probe serves depends only on the quality of the material. When using bronze or heat-resistant steel, it can be eternal, but sometimes (every 20–30 thousand km) it requires cleaning the hole from carbon deposits.

For newer cars, you need a snag with a mini-catalyst inside, which also has a limited resource. After the development of the catalytic filler (occurs over 50100 thousand km), it ceases to cope with the tasks assigned and turns into a complete analogue of a simple screw. In this case, the simulator must be changed or filled with fresh catalytic material.

Electronic snags are theoretically not prone to breakage and wear, as they do not experience mechanical stress. But the resource of radio components (resistors, capacitors) is limited, over time they degrade and lose their properties. The emulator may fail prematurely if dust or moisture gets on the components due to a leak.

| The type of drug addiction | Car Compatibility | How to maintain a snag LZ | How long does a snag LZ live (how often to change) |

|---|---|---|---|

| Mechanical (screwdriver) | 1999–2004 (EU production), up to 2013 (Russian production), cars up to Euro-3 inclusive. | Periodically (every 20-30 thousand km), it may be necessary to clean the hole and the cavity of the sensor from carbon deposits. | Theoretically eternal (just a mechanical adapter, there is nothing to break). |

| Mechanical (mini-catalyst) | From 2005 (EU) or 2013 (Russia) to present c., class Euro-3 and above. | After working out the resource, it requires replacement or replacement of the catalytic filler. | 50-100 thousand km, depending on the quality of the filler. |

| Electronic board) | Independent emulators up to 2005 (EU) or up to 2013 (Russia) of the year of manufacture, environmental class Euro-2 or Euro-3 (where it is worth installing HBO 2 and 3 generations). Emulators using the readings of the first DC to deceive the second lambda probe - from 2005 (EU) or 2008 (Russia) to present. c., class Euro-3 and higher, but exceptions are possible, the correct selection of denominations is important. | Maintenance is not required if located in a dry, clean place and isolated from moisture and dirt. | Depends on the quality of the electronic components. Should last the lifetime of the car, but electrolytes and/or resistors may need to be re-soldered if poor quality parts are used. |

| Electronic (resistor and capacitor) | Car from 2005 (EU) or 2008 (Russia), Euro-3 class and above. | Periodically it is worth inspecting for the integrity of the elements. | Depends on the quality of the radio components and the correct selection of ratings. If the components are selected correctly, do not overheat and do not get wet, it may be enough for the entire life of the car. |

Which lambda snag is better

Definitely answer the question “Which lambda snag is better?” impossible. Each device has its pros and cons, different compatibility with certain models. Which snag of a lambda probe is better to put - depends on the purpose of this manipulation and the specific conditions:

- mechanical snags operate only together with a working oxygen sensor;

- to simulate the normal operation of the oxygen sensor on the old HBO, only electronic tricks with a microcontroller (pulse generator) are suitable;

- on old cars of a class not higher than Euro-3, it is better to put a snag-screw - cheap and reliable;

- on more modern cars (Euro-4 and above), it is better to use mini-catalysts;

- the option with a resistor and a capacitor is a cheaper, but less reliable type of snag for new cars;

- an emulator of the second lambda probe on a microcontroller that works from the first one is the best option for a car with a failed or removed second oxygen sensor.

Generally speaking, it is the mini-catalyst that is the best option for a serviceable DC, because it imitates the operation of a standard converter with high accuracy. A microcontroller is a more complex and expensive option, and therefore is only appropriate when there is no standard sensor at all or it needs to be deceived to drive on gas.