The main types of asphalt concrete mixtures

The standard composition of asphalt concrete is approximately the following: crushed stone, sand (crushed or natural), mineral powder and bitumen. The final composition of the coating is obtained by correctly calculating the proportions, observing a certain temperature and compaction using a special technique.

Asphalt concrete base - a binder obtained by mixing mineral powder and bitumen. After mixing sand in such a substance, a mixture is obtained, called an asphalt solution.

Liquid asphalt - this is an indispensable tool for detecting cracks in the coating and with its help you can easily eliminate crevices https://xn--80aakhkbhgn2dnv0i.xn--p1ai/product/mastika-05. In order to increase the service life of the asphalt pavement many times over, Mastic 05 is a tool that can be used even without special experience and skill in the field of asphalt work.

There are several types of asphalt concrete mixes. They are distinguished by the temperature at which the composition is laid, and by the degree of viscosity of bitumen. These mixtures are hot, warm and cold. Below we will discuss the principle of laying using different types of asphalt mixes.

1. Hot asphalt mix is prepared using viscous bitumen. The temperature of preparation of the composition is kept within the range of 140-160 ° C, while laying is carried out at a temperature of about 120 ° C (but not less than that). The structure is formed during the compaction process.

2. Mixes of medium temperature level (warm), during preparation require temperatures from 90 to 130 ° C. The flooring is carried out at t = 50-80 ° C. In this case, the structure takes longer to form - from a couple of hours to two weeks. The timing depends on the type of bitumen used.

3. For the preparation of the third type of mixtures - cold, liquid bitumen is used. The temperature regime is required here exclusively during the preparation period (up to 120 ° C), while laying is done after the mixture has cooled. There is, of course, in such technology and a minus - the period of solidification and formation of the structure of the mixture in this case is much longer - from 20 days to a month. The term also depends on the type and speed of thickening of the selected bitumen, and on transport traffic, and on weather conditions.

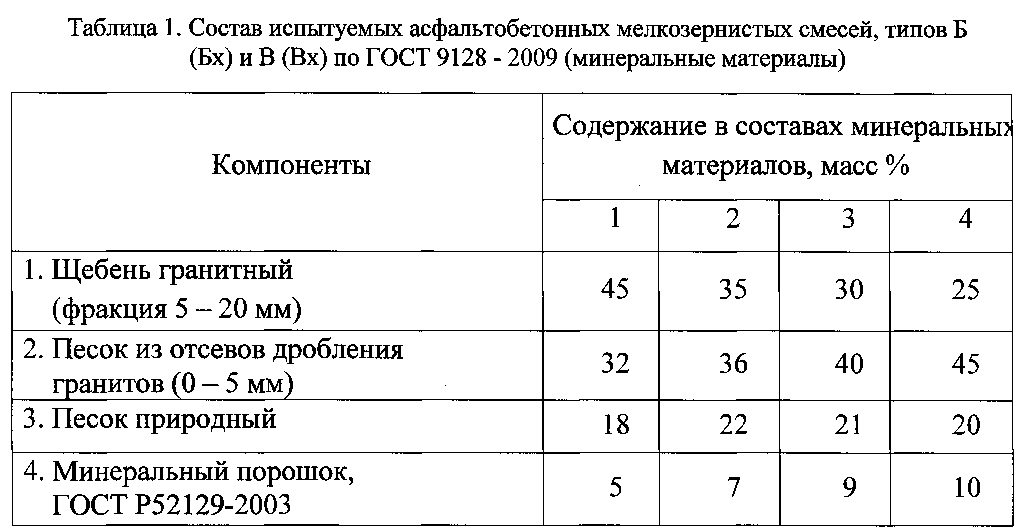

Also, the types of asphalt concrete mixtures are distinguished depending on the particle size of the solid, mineral part of the composition. There is coarse-grained asphalt concrete (particle size - up to 25 mm), fine-grained (up to 15 mm) and sandy (maximum grain size - 5 mm).

According to the composition and types of bases, the following types of asphalt concrete mixtures are distinguished:

a) for the preparation of warm and hot dense asphalt concrete composition:

• polygravel (rubble content in the composition - 50-65%);

• medium crushed stone (35-50% crushed stone);

• low-crushed stone (20-35% crushed stone in the mixture);

• sandy with crushed sand, particle size 1,25-5,00 mm;

• sandy based on natural sand,

• particle size - 1,25-5,00 mm;

b) for the preparation of cold-type asphalt concrete:

• crushed stone - fractions 5-15 or 3-10 mm;

• low gravel - fractions 5-15 or 3-10 mm;

• sandy, with a particle size of 1,25-5,00 mm;

The bottom layer of asphalt concrete pavement is usually made with a calculation of 50-70 percent of crushed stone. Also, the type of asphalt mix depends on the compaction method applied to the pavement layer. There are mixtures cast, rammed, rolled and vibrated (compacted with a vibrating plate).