Design features and principle of operation of the non-contact ignition system VAZ 2107

Content

Ignition problems in cars of the Zhiguli family occur quite often. Their reasons are usually related to the quality of production of the nodes that are responsible for sparking. Only one thing pleases - most breakdowns of the ignition system can be eliminated on their own, because the "seven" does not differ in the complexity of its design.

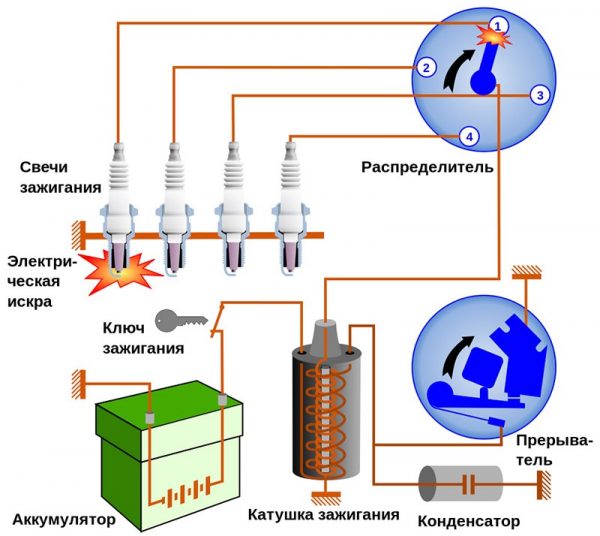

Non-contact type ignition system

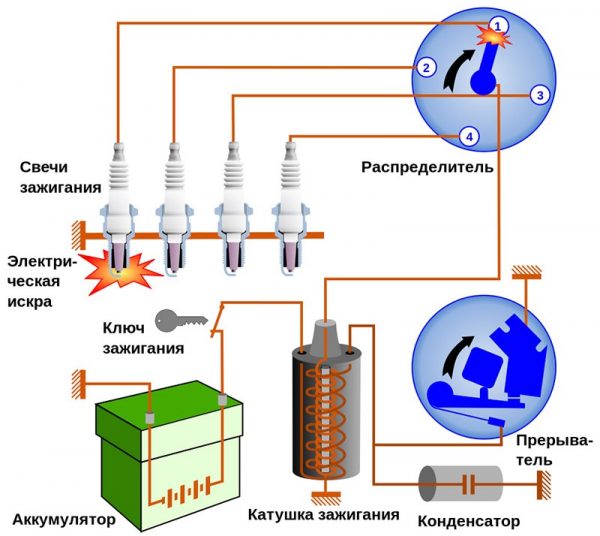

The ignition system (IS) is used to create a pulsed voltage and timely ignition of the combustible mixture in the combustion chambers of the power unit. It is the main part of the car's energy supply system.

The evolution of the ignition of the "seven" began with a contact type mechanism. Its feature was the process of generating an electrical impulse with the help of a group of contacts located in the distributor. The constant mechanical and electrical loads that the contacts in such a system were subjected to led to the fact that car owners very often had to clean them, change and adjust the gap between them. In principle, this was the only significant drawback of the contact type ignition, and drivers, when there were problems with the ignition of the mixture, knew exactly what needed to be checked and repaired.

In the early 90s of the last century, the "sevens" received contactless ignition. It greatly facilitated the life of the owners of these cars, because in its design there were no longer any burning contacts that required constant adjustment. They were replaced by an electronic switch that does not require any maintenance.

The design of the contactless ignition system and the principle of its operation

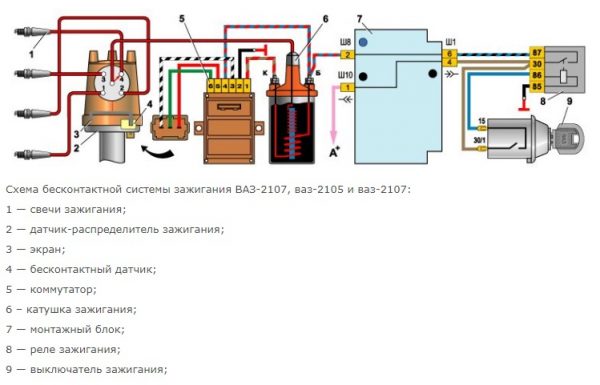

Contactless ignition system (BSZ) VAZ 2107 includes:

- electronic (transistor) switch;

- transformer coil (two-winding);

- distributor (distributor) with Hall sensor, contact cover and slider;

- a set of high-voltage wires;

- candles.

Each of these elements is a separate part and performs its functions independently of other nodes. Sparking in a VAZ 2107 engine with a non-contact type ignition system occurs according to the following algorithm:

- When voltage is applied to the starter, its rotor begins to rotate the crankshaft, which, in turn, scrolls the distributor shaft with the slider.

- The Hall sensor reacts to this rotation, registers the rotation of the distributor shaft and transmits a signal to the switch. The latter, having received a signal from the sensor, turns off the current supplied to the primary (low-voltage) winding of the coil.

- At the moment the current is turned off in the secondary winding of the transformer, a powerful voltage pulse arises, which is transmitted through the central wire to the slider (moving contact) located at the end of the distributor shaft.

- The slider, moving in a circle, alternately comes into contact with four fixed contacts located in the distributor cover. At certain moments, it transmits voltage to each of them.

- From a stationary contact, current through a high-voltage wire enters the spark plug, causing sparking at its electrodes.

In a contactless ignition system, the role of a breaker is performed by a Hall sensor and a switch

In a contactless ignition system, the role of a breaker is performed by a Hall sensor and a switch

Switch

The switch is necessary to create an electrical impulse by interrupting the constant supply of current from the battery to the primary winding of the coil. In the BSZ VAZ 2107, a switching device of type 3620.3734 is used. The working elements in it are ordinary bipolar transistors, which provide opening of the circuit at the moment a signal is received from the Hall sensor.

The 3620.3734 switch is built according to a simple single-wire circuit, in which the device body is connected to the car's "mass" and, accordingly, to the negative terminal of the battery. The advantages of using this node instead of a traditional breaker include:

- no need for maintenance and adjustment;

- high spark energy, which makes it easier to start the engine in the cold season, as well as the possibility of using gasoline with a lower octane number;

- the presence of a stabilization system that protects the Hall sensor from voltage surges.

There is only one drawback of this switch - the low quality of production. It happens that the device fails after a few months of operation. Its design is non-separable, therefore, repair is impossible. That is why experienced owners of "sevens" and other VAZs with a contactless ignition system carry spare switches in their cars. Fortunately, the part is inexpensive - 400-500 rubles.

Table: main technical characteristics of the switching unit type 3620.3734

| Features | Indicators |

| Operating voltage, V | 12 |

| Voltage range, V | 6 – 18 Feet |

| Permissible action of voltage exceeding the range for 5 s, V | 25 |

| Switching current, A | 7,5±0,5 |

| Current interruption time, s | 1 – 2 Feet |

| Rated impulse overvoltage, V | 150 |

| Temperature Range, 0С | -40 - +80 |

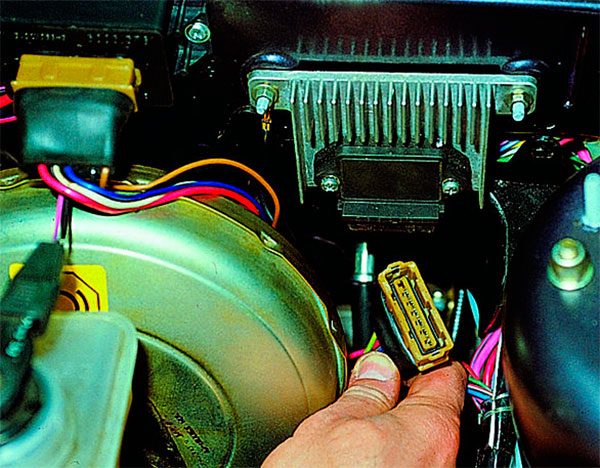

Where in the "seven" is the switch

Depending on the modification and year of manufacture of the car, the switch in the VAZ 2107 may have a different location. It is usually installed on the mudguard on the left side of the engine compartment or on the engine shield. In any case, you need to look for it next to the ignition coil.

Typical switch failures

There are only two signs of a malfunction in the switch: the engine either does not start at all, or it starts, but is unstable. It is impossible to determine what exactly it failed without a thorough diagnosis, since similar symptoms may be inherent in other breakdowns.

Failure of electronics

Most often, the switching device simply burns out. Rather, one or more of its electronic elements located inside burn out. In this case, there will be no spark either on the central armored wire going from the coil to the distributor, or on the electrodes of the candles.

Signal delay

It also happens that the engine starts, but works intermittently, overheats, stalls periodically. Similar symptoms accompany many other problems, including improper carburetor adjustment, fuel pump breakdown, clogged fuel lines, breakdown of the coil, high-voltage wires, etc. A faulty switch can cause these symptoms due to distortion of the shape of the output electrical impulses. Usually there is a delay in the signal, which leads to a shift in the moment of sparking back.

How to check the VAZ 2107 switch

At service stations, switches are checked on a special stand using an oscilloscope. But, given the low cost of the part, it is not advisable to pay for its diagnostics at the service station. At home, it will not be possible to accurately check the switching device, but there are three options for how to do this without involving specialists:

- using a new switch;

- by means of a control lamp;

- with a piece of wire.

The first option involves replacing the device with a new one or a known good one. For this you need:

- Remove the "negative" terminal from the battery.

- Disconnect the connector from the switch under test.

- Connect the connector to a working switch.

- Attach the terminal to the battery.

- Start the engine and check its operation.

To check the switch, the easiest way is to temporarily replace it with a new one or a known good one and start the engine

To check the switch, the easiest way is to temporarily replace it with a new one or a known good one and start the engine

If the engine started and began to work normally, the problem was in the switch.

To check the second way, you need a test lamp. This is a simple device, consisting of a conventional twelve-volt car lamp and wires connected to it. Diagnostics is performed as follows:

- Using an 8 mm wrench, unscrew the nut on the ignition coil, which attaches the wire to the "K" terminal.

- We connect a test lamp in the gap between the indicated terminal and the end of the removed wire.

- We ask the assistant to sit behind the wheel and start the starter.

To check the health of the switch, you need to disconnect the wire from the “K” contact and connect a control light to the open circuit

To check the health of the switch, you need to disconnect the wire from the “K” contact and connect a control light to the open circuit

If the switch is working properly, the lamp should flash. This is evidence that the device reads the signals of the Hall sensor and periodically breaks the circuit. If the lamp is on constantly or does not light up at all, the switch is faulty.

Video: switch diagnostics using a lamp

The third way is the most radical. It is perfect for those drivers who are caught on the road by a malfunction when there is neither a new switch nor a warning lamp at hand. For its implementation, only a piece of insulated wire with a cross section of 0,5 mm or more is required2. The procedure is as follows:

- We disconnect the central high-voltage wire from the cover of the distributor.

- We put it on some metal assembly of the engine or body in such a way that the contact of the core is next to the "mass".

- Disconnect the connector from the Hall sensor on the distributor.

- We clean the ends of the wire segment from the insulation. We stick one of them into the central hole of the sensor connector. We turn on the ignition without starting the starter.

- With the other end of the piece of wire, touch the "mass" of the car in any convenient place. If the switch is in good condition, sparking will be observed between the central high-voltage wire and ground. Otherwise, the device must be replaced.

Video: checking the switch with a piece of wire

Watch this video on YouTube

Ignition coil

The ignition coil acts as a step-up transformer, increasing the voltage from 12 volts to 24 or more kilovolts. In VAZ 2107 cars with contactless ignition, a coil of type 27.3705 is used. All carburetor Samaras were equipped with the same transformers.

Table: technical data of transformer coil type 27.3705

| Features | Indicators |

| Operating voltage, V | 12 |

| Output voltage, kV | 22 |

| The value of the resistance of the primary winding, Ohm | 0,45 – 0,5 Feet |

| The value of the resistance of the high-voltage winding, kOhm | 5 – 5,5 Feet |

| Inductance, mH | 3,9 |

| Secondary voltage growth time up to 15 kV, μs | no more 21 |

| Discharge energy, mJ | 60 |

| Discharge duration, ms | 2 |

| Weight, g | 860 |

| Temperature Range, 0С | -40 - +85 |

Coil Location

In the "sevens" the ignition coil is installed in the engine compartment on the left. Usually it is fixed on a special bracket under the expansion tank. Sometimes car owners move the coil to a safer place, such as a motor shield, to protect it from moisture and process fluids. You can find the coil by the central high-voltage wire that connects it to the cover of the distributor.

Coil malfunctions and their symptoms

Of all the components of the ignition system, the coil is considered the most reliable node. Its resource is unlimited, but it happens that it also fails. The main causes of transformer failure are burnout or short circuit in the windings. If this happens, the spark disappears altogether, because the distributor stops being energized.

Methods for checking the ignition coil VAZ 2107

There are two ways to check the coil for performance: coarse and fine. In the first case, you need:

- Disconnect the end of the center wire from the distributor cap and insert a known-good spark plug into the tip.

- Lay the wire with the candle so that the skirt of the candle touches the "ground" of the car.

- Ask an assistant to get behind the wheel and start the starter.

If a spark appears between the electrodes of the spark plug when the engine is started, then the ignition coil is working.

If a spark appears between the electrodes of the spark plug when the engine is started, then the ignition coil is working.

With a working coil, sparking will be observed between the electrodes of the candle. Pay attention to the spark itself. It should be stable and have a light blue tint. If there is no spark, it is necessary to make a more accurate diagnosis, since not only the coil, but also the switch, the Hall sensor, and the ignition switch may be to blame.

To accurately check the coil, you will need an ohmmeter or multimeter with a resistance measurement function. The check procedure is as follows:

- Using a 13 mm wrench, unscrew the nuts securing the coil to the bracket. Disconnect all wires from it and remove from the car.

- We clean the body from dirt and dust.

- We turn on the ohmmeter in the measurement range of 0–20 ohms.

- We connect the probes of the device to the side terminals of the coil (low voltage winding leads), look at the readings. They should be in the range of 0,45-0,5 ohms.

When connecting probes to the extreme terminals of the coil, the multimeter should show a resistance of 0,45–0,5 ohms

When connecting probes to the extreme terminals of the coil, the multimeter should show a resistance of 0,45–0,5 ohms - To check the integrity of the secondary winding, we connect one ohmmeter probe to the central terminal, and the second to the terminal marked "+ B". We switch the device in the range of 0–20 kOhm and look at the readings. For the working coil, the resistance of the secondary winding should be in the range of 5–5,5 kOhm.

The resistance between the central terminal and the “+ B” terminal of a working coil should be in the range from 5 to 5,5 kOhm

The resistance between the central terminal and the “+ B” terminal of a working coil should be in the range from 5 to 5,5 kOhm

If the meter readings differ from those indicated, the coil must be replaced.

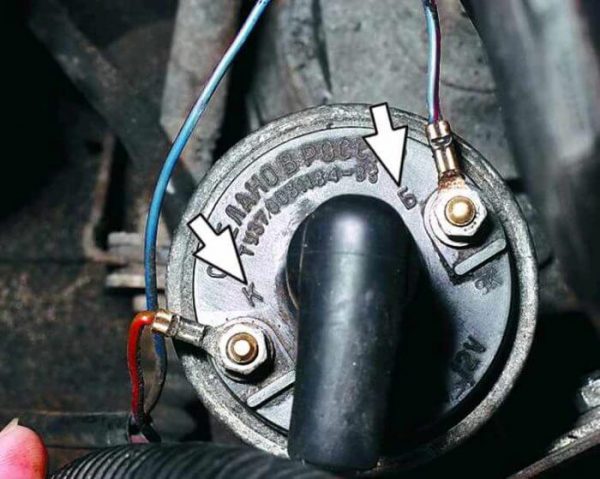

Distributor

The ignition distributor (distributor) is designed to transmit high voltage current pulses that come from the coil to the candles. The distributor consists of:

- aluminum case;

- shaft;

- Hall sensor;

- vacuum and centrifugal ignition timing regulators;

- fugitive;

- covers with four fixed contacts.

In the "sevens" with contactless ignition, distributors of the 38.3706 type are used.

Table: technical characteristics of the distributor type 38.3706

| Features | Indicators |

| Supply voltage | 12 |

| Permissible speed, rpm | 3500 |

| Turning on the centrifugal regulator at, rpm | 400 |

| The maximum value of the angle of the centrifugal regulator, o | 15,5 |

| Inclusion of the vacuum regulator at, mm. rt. Art. | 85 |

| The maximum value of the angle of the vacuum regulator, o | 6 |

| Operating temperature range, oС | -40 - +100 |

| Weight, kg | 1,05 |

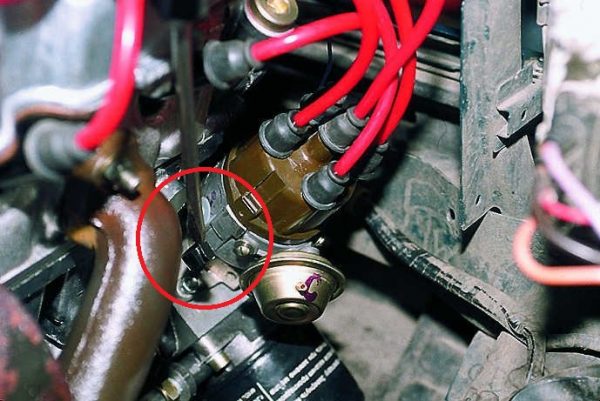

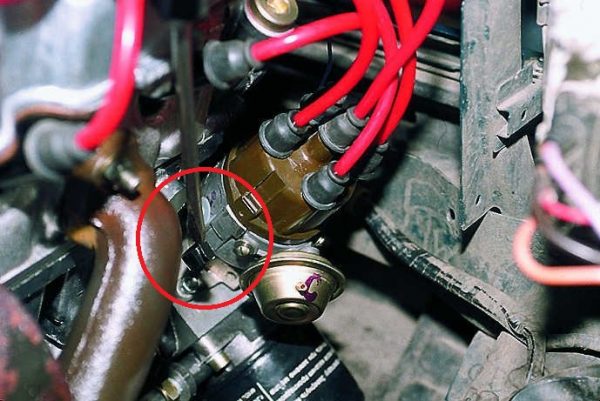

Where is the distributor in the VAZ 2107

The ignition distributor is mounted on the left side of the engine block. Its shaft is driven by the accessory drive gear. The number of revolutions of the distributor shaft directly depends on the speed of rotation of the crankshaft.

Malfunctions of the VAZ 2107 distributor and their symptoms

The most common breakdowns of the "seven" distributor include:

- burning of fixed contacts of the cover;

- mechanical damage or electrical breakdown of the cover;

- ignition of the fume hood.

As for the symptoms, for the listed problems they will be similar:

- unstable engine operation;

- reduction in the power characteristics of the power plant;

- increased fuel consumption.

To diagnose the main breakdowns of the distributor, it does not need to be removed from the engine. It is enough to disconnect the high-voltage wires from the cover and unfasten the two latches that secure it to the body. After removing the cover and inspecting the contacts with the slider, you can visually assess their condition and conclude how suitable they are for further work. If the contacts cannot be cleaned, the device cover must be replaced. Such a detail costs about 200 rubles. The runner will cost twice as much.

Armored wires

High voltage wires are used to transmit impulse voltage from the ignition coil to the fixed contacts of the distributor cover, and from there to the central electrodes of the spark plugs. VAZ 2107 has five such wires. Structurally, each of them consists of a conductive core, several layers of insulation (PVC or silicone) and lugs.

Wire faults

Armored wires can have only three faults:

- breakdown of the insulating layer;

- breakage of the current-carrying core;

- core wear.

The failure of one or more simultaneously high-voltage wires is accompanied by the following symptoms:

- "triple" of the motor;

- its difficult start;

- drop in power of the power unit;

- increase in the amount of fuel consumed.

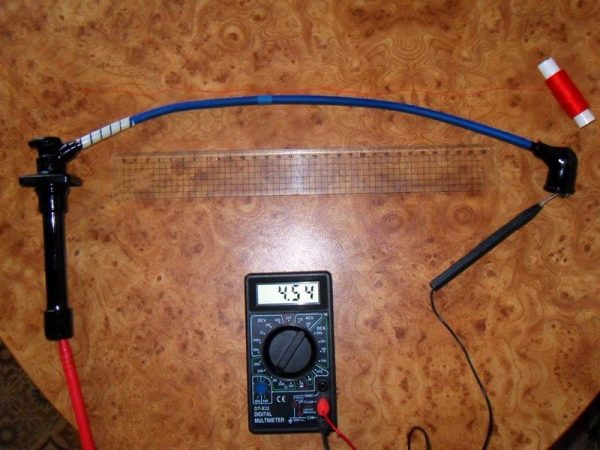

How to check high voltage wires

Checking armored wires consists in determining the integrity of their insulation and establishing the resistance of conductive wires. To assess the condition of the insulating layer, it is enough to remove the wires, clean them of dirt and inspect them, scrolling and bending them in your hands. If during such a check it is found that at least one of them has cracks, severe abrasions, traces of electrical breakdown, the entire set should be replaced.

Long-term operation of high voltage wires leads to wear of the conductive core, as a result of which its resistance changes up or down. Naturally, this affects the magnitude of the transmitted voltage and spark energy.

The process for measuring wire resistance is as follows:

- We turn on the ohmmeter, translate it into the range of 0-20 kOhm.

- We connect the probes of the device to the ends of the conductive core.

- We look at the readings of the ohmmeter. Serviceable wires, depending on the manufacturer and the period of operation, may have a resistance in the range of 3,5–10 kOhm. If the indicators are different, we change the wires as a set.

The core resistance should be in the range of 3,5–10 kOhm

The core resistance should be in the range of 3,5–10 kOhm

Video: checking armored wires

Watch this video on YouTube

Candles

The task of the spark plug is to generate a powerful electrical spark to ignite the fuel-air mixture. The basis of the design of the candle is:

- a central electrode through which a high voltage current flows;

- ceramic insulator;

- threaded part (skirt);

- side electrode.

What candles are used in the BSZ VAZ 2107

In electronic BSZ, it is recommended to use candles of the following manufacturers and types:

- A17DV and their modifications (Russia, Engels, ZAZS);

- BP-6 E (Japan, NGK);

- W20-EP (Japan, DENSO);

- L15Y (Czech Republic, BRISK);

- W-7D (BERU Germany, BERU).

The interelectrode gap of candles for BSZ should be within 0,7–0,8 mm

The interelectrode gap of candles for BSZ should be within 0,7–0,8 mm

Table: main characteristics of BSZ spark plugs

| Features | Indicators |

| Threaded part height, mm | 19 |

| Thread Type | M14 / 1,25 |

| Heat number | 17 |

| Gap size, mm | 0,7 – 0,8 Feet |

Installing an electronic BSZ instead of a contact

Today, meeting the "seven" with contact ignition is a rarity. With the sale of switches, distributors and coils for electronic sparking systems, the owners of the classics began to massively re-equip their cars.

What is included in the BSZ kit

The process of converting a contact system into an electronic one is quite simple, and also inexpensive. The cost of an electronic ignition kit for the VAZ 2107 is about 2500 rubles. It includes:

- transistor switch type 3620.3734 with connector;

- coil 27.3705;

- contactless distributor type 38.3706;

- connecting wires.

Elements of the contactless ignition system can be purchased as a set or separately

Elements of the contactless ignition system can be purchased as a set or separately

In addition, you will need candles (preferably new ones) with a gap of 0,7-0,8 mm and a set of high voltage wires. Coil type B-117A (used in a contactless system) is not suitable for electronic ignition. Its characteristics do not match those of other equipment in the circuit.

Video: an overview of the elements of the BSZ on the "classics"

Watch this video on YouTube

Required Tools

To complete the work you will need:

- wrenches for 8, 10 and 13 mm;

- a screwdriver with a cross-shaped blade;

- drill;

- candle key;

- 36 mm wrench or ratchet for turning the crankshaft;

- self-tapping screws;

- passatizhi.

To turn the crankshaft, it is more convenient to use a special ratchet wrench.

To turn the crankshaft, it is more convenient to use a special ratchet wrench.

The order of work

Work on the conversion of the ignition system to contactless is carried out in the following order:

- Disconnect the terminals from the battery. We remove the battery, put it aside.

- We remove the high voltage caps from the cover of the distributor and from the candles.

- Using a special key, we unscrew all the candles. We screw new ones in their place.

To replace the candles with new ones, you will need a special key.

To replace the candles with new ones, you will need a special key. - Using a drill, we drill holes on the left mudguard or on the motor shield for mounting the switch.

- We fix the switch to the car body with self-tapping screws.

The switch can be installed either on the left fender or on the motor shield

The switch can be installed either on the left fender or on the motor shield - Remove the distributor cap.

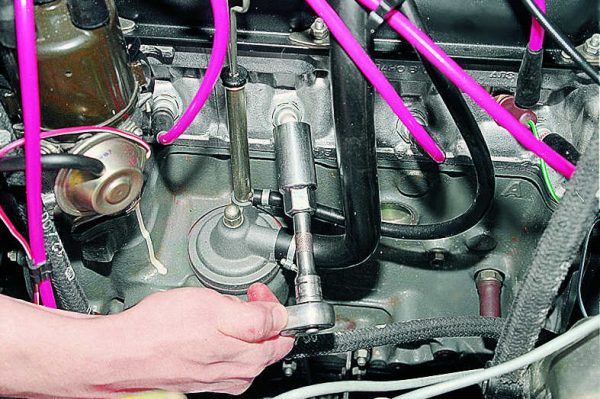

- We scroll the crankshaft by throwing a wrench on the nut of its pulley until the distributor slider is aimed at the candle of the first cylinder, and the mark on the pulley indicates the middle ebb on the timing cover.

The mark in the form of a vertical thickening must be aligned with the middle risk on the timing cover

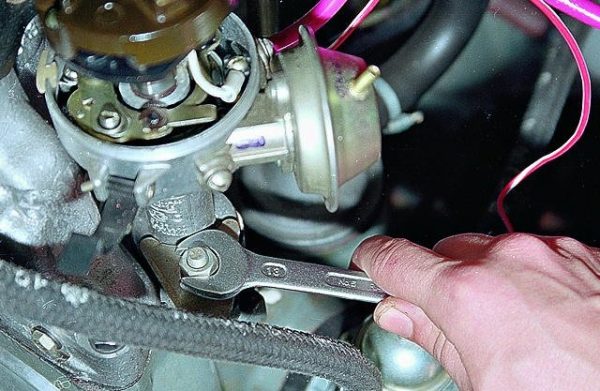

The mark in the form of a vertical thickening must be aligned with the middle risk on the timing cover - Using a 13 mm wrench, loosen the distributor mounting nut.

The distributor is fastened with a single 13 mm wrench nut

The distributor is fastened with a single 13 mm wrench nut - Remove the vacuum hose from the distributor and disconnect all wires.

The vacuum hose is put on the fitting of the ignition regulator

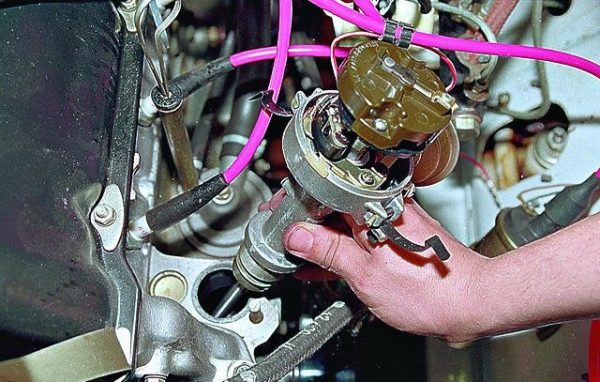

The vacuum hose is put on the fitting of the ignition regulator - We remove the old distributor from its seat.

- Remove the cover from the new distributor.

- Trying it on in place of the old one, rotate the slider by hand until it is directed towards the first cylinder.

- We install a new distributor, bait the nut, but do not tighten it completely.

When installing the distributor, the slider should point to the first cylinder

When installing the distributor, the slider should point to the first cylinder - We connect the wire connectors and the hose of the vacuum regulator to the new distributor.

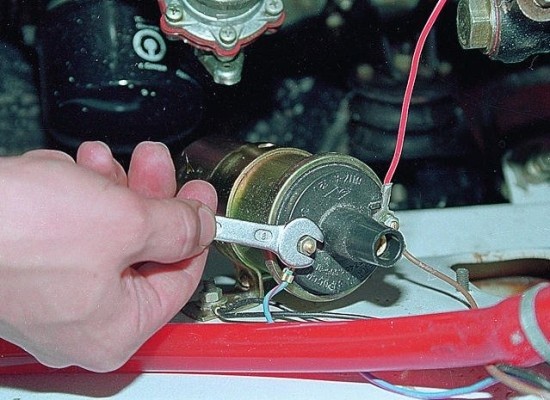

- We dismantle the old ignition coil by unscrewing the nuts of its fastening with a 13 mm wrench. Disconnect all wires from it.

- Install the new coil.

- We connect the connector with the wiring harness to the switch.

- We clean the ends of the wires. We make the installation of the chain:

- we securely fasten the black wire from the switch to the "ground" with a self-tapping screw or screw;

- connect the red wire to the "K" terminal on the coil. We also attach the brown wire from the tachometer here;

- connect the blue wire from the switch and blue with a black stripe to the “+ B” terminal on the coil.

Red and brown wires are connected to the "K" terminal, blue and blue with black - to the "+ B" terminal

Red and brown wires are connected to the "K" terminal, blue and blue with black - to the "+ B" terminal

- We install the cover of the distributor, fix it. We connect new high-voltage wires to the cover and candles.

- We are trying to start the engine. If it worked, then everything was done correctly. Otherwise, we check the ignition circuit and the reliability of connecting its elements.

Video: installing BSZ on a "classic" VAZ

Watch this video on YouTube

Ignition setting VAZ 2107

After installing new components of the system, it is recommended to check the correct setting of the ignition timing and its advance angle. If necessary, they must be adjusted.

Setting the ignition timing involves setting the crankshaft pulley according to the marks, as well as adjusting the position of the distributor shaft. The order of work is as follows:

- We determine what fuel will be used in the car. If it is gasoline with an octane rating below 92, we focus on the first ebb on the cover of the timing gear drive. In all other cases, our reference point is the second (middle) mark.

The regular VAZ 2107 engine is designed for AI-92 gasoline, so the crankshaft mark must be set to the second ebb

The regular VAZ 2107 engine is designed for AI-92 gasoline, so the crankshaft mark must be set to the second ebb - Turn the crankshaft with a 36 mm key until the mark on its pulley exactly matches the selected ebb on the cover.

- We pass to the engine compartment. Previously, we installed the distributor, but did not completely fix it. Remove the cover from the device. If the slider of the device does not point to the candle of the first cylinder, carefully turn the entire distributor to the most exact match.

- Next we need a control lamp. We connect one of its wires to the “K” terminal of the coil, the second to the “mass”. Turn on the ignition, look at the lamp. If it is on, slowly scroll the distributor housing to the left until the lamp goes out. When this happens, again, slowly rotate the distributor clockwise until it lights up.

The position of the distributor at the moment the lamp is turned on and off corresponds to the correct ignition timing.

The position of the distributor at the moment the lamp is turned on and off corresponds to the correct ignition timing. - Tighten the distributor mounting nut with a 13 mm wrench. We fix the lid. We check the operation of the engine.

At this stage, in principle, the ignition adjustment can be completed. All major work has been done. However, for a more precise setting of the moment of sparking, it is advisable to check how the car's engine behaves on the road: how it picks up speed, is there enough power, etc.

Precise ignition control in service stations is carried out using a stroboscope. We do not need it, we will do everything by ear. The adjustment algorithm is as follows:

- We leave on a safe section of a flat road with low traffic intensity.

- We accelerate the car to 60-70 km / h.

- We turn on the fourth gear.

- We sharply press on the gas pedal, pressing it to the floor. Hold it like that for 3-4 seconds. If the engine “chokes” at the same time, a failure appears - our ignition is late. In this case, we stop, raise the hood, loosen the distributor nut and turn it a little to the right. Repeat the procedure until the engine clearly responds to pressing the pedal. With the correct ignition setting, at the moment you press the gas, a short ringing of the piston fingers is heard, which stops after one to two seconds.

- If the engine does not “choke”, but reacts normally, but at the same time the ringing of the fingers becomes constant, ignition must be done later by turning the distributor counterclockwise.

In practice, such a setting is more than enough for normal operation of the machine, but after replacing the elements of the ignition system, it will not be superfluous to adjust the carburetor, adjusting it to the new spark parameters.

As you can see, there is nothing complicated either in the design, or in the installation, or in the adjustment of contactless ignition. It is thanks to this that it has earned the trust of the owners of the domestic "classics".