P0130 Oxygen Sensor Circuit Malfunction (Bank 2 Sensor 1)

Content

DTC P0130 - OBD-II Data Sheet

O2 Sensor Circuit Malfunction (Bank 1 Sensor 1)

DTC P0130 is set when the engine control module (ECU, ECM, or PCM) detects a malfunction in the heated oxygen sensor (bank 1, sensor 1) circuit.

What does trouble code P0130 mean?

This Diagnostic Trouble Code (DTC) is a generic transmission code, which means it applies to OBD-II equipped vehicles. Although general, specific repair steps may differ depending on the brand / model.

The O2 sensor outputs voltage based on the oxygen content in the exhaust gases. The voltage ranges from 1 to 9 V, where 1 indicates lean and 9 indicates rich.

The ECM constantly monitors this closed-loop voltage to determine how much fuel to inject. If the ECM determines that the O2 sensor voltage has been too low (less than 4V) for too long (more than 20 seconds (time varies by model)), this code will set.

Possible symptoms

Depending on whether the problem is intermittent or not, there may be no other symptoms other than the MIL (Malfunction Indicator Lamp) illuminated. If the problem persists, symptoms may include one or more of the following:

- Illumination MIL

- Engine runs rough, stalls or stumbles

- Blowing black smoke from the exhaust pipe

- Engine stalls

- Poor fuel economy

Causes of the P0130 code

A faulty oxygen sensor is usually the cause of the P0130 code, but this is not always the case. If your o2 sensors have not been replaced and are old, you can bet the sensor is the problem. But it can be caused by any of the following reasons:

- Water or corrosion in the connector

- Loose terminals in the connector

- Burnt exhaust system wiring

- Open or short circuit in wiring due to friction on engine parts.

- Holes in the exhaust system through which unmetered oxygen enters the exhaust system.

- Unmeasured engine vacuum leak

- Defective o2 sensor

- Bad PCM

- Loose connector terminals.

- The presence of openings in the exhaust system through which an excess and uncontrolled amount of oxygen enters the exhaust system.

- Incorrect fuel pressure.

- Defective fuel injector.

- Malfunction of the engine control module.

Possible solutions

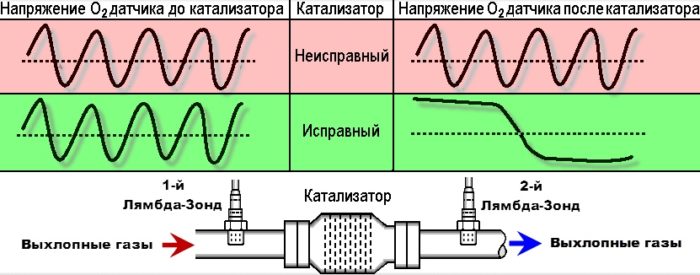

Use a scan tool to determine if Bank 1 Sensor 1 switches correctly. It should switch quickly and evenly between rich and lean.

1. If so, the problem is most likely temporary and you should inspect the wiring for visible damage. Then perform the wiggle test by manipulating the connector and wiring while observing the voltage of the o2 sensor. If it falls out, secure the appropriate part of the wire harness where the problem is.

2. If it does not switch properly, try to determine if the sensor is reading the exhaust correctly or not. Do this by briefly removing the vacuum from the fuel pressure regulator. The o2 sensor reading should become rich in response to the added fuel. Replace the regulator power supply. Then create a lean mixture by disconnecting the vacuum line from the intake manifold. The o2 sensor reading should be poor when responding to cleaned exhaust. If the sensor is working properly, the sensor may be OK and the problem could be holes in the exhaust or an unmeasured engine vacuum leak (NOTE: Unmeasured engine vacuum leaks are almost always accompanied by Lean Codes. See Related Unmetered Leak Diagnosis Articles) vacuum). If there are holes in the exhaust, it is possible that the o2 sensor is reading the exhaust incorrectly due to additional oxygen entering the pipe through these holes.

3. If it does not and the o2 sensor simply does not switch or is running slowly, unplug the sensor and make sure the sensor is supplied with a 5 volt reference. Then test for 12 volts on the o2 sensor heater circuit. Also check the continuity of the ground circuit. If any of this is missing or the voltage is abnormal, repair the open or short circuit in the appropriate wire. The o2 sensor will not work properly without proper voltage. If the correct voltage is present, replace the o2 sensor.

Repair Tips

After the vehicle is taken to the workshop, the mechanic will usually perform the following steps to properly diagnose the problem:

- Scan for error codes with an appropriate OBC-II scanner. Once this is done and after the codes have been reset, we will continue to test drive on the road to see if the codes reappear.

- Checking the oxygen sensor.

- Inspection of the electrical wiring system.

- Connector inspection.

Hurry replacement of the oxygen sensor is not recommended, as the cause of the P0139 DTC may lie in something else, for example, in a short circuit or loose connector contacts.

Generally, the repair that most often cleans up this code is as follows:

- Repair or replace the oxygen sensor.

- Replacement of faulty electrical wiring elements.

- Connector repair.

Driving with a P0130 error code, while possible, is not recommended as it can have serious consequences for the vehicle's stability on the road. For this reason, you should take your car to the garage as soon as possible. Given the complexity of the inspections being carried out, the DIY option in the home garage is unfortunately not feasible.

It is difficult to estimate the upcoming costs, since a lot depends on the results of the diagnostics carried out by the mechanic. As a rule, the cost of replacing an oxygen sensor in a workshop, depending on the model, can range from 100 to 500 euros.

Frequently Asked Questions (FAQ)

What does code P0130 mean?

What causes the P0130 code?

A faulty oxygen sensor and faulty wiring are the most common causes of this DTC.

How to fix code P0130?

Carefully check the oxygen sensor and all connected components, including the wiring system.

Can code P0130 go away on its own?

In some cases, this error code may disappear on its own. In any case, it is recommended to always check the oxygen sensor.

Can I drive with code P0130?

Driving with this error code, while possible, is not recommended.

How much does it cost to fix code P0130?

As a rule, the cost of replacing an oxygen sensor in a workshop, depending on the model, can range from 100 to 500 euros.

Need more help with your p0130 code?

If you still need help with DTC P0130, post a question in the comments below this article.

NOTE. This information is provided for informational purposes only. It is not intended to be used as a repair recommendation and we are not responsible for any action you take on any vehicle. All information on this site is protected by copyright.

One comment

ROQUE MORALES SANTIAGO

I HAVE A 2010 XTREIL, THE REVOLUTIONS GO UP AND DOWN, THE WEATHER GONE AND IT COMES BACK, I TURN IT ON AND PULL WELL THEN I TURN IT OFF AND IN FIVE MINUTES I WANT TO TURN IT ON IT DOESN'T START IT HAS POWER I HAVE TO WAIT TWENTY MINUTES AND IT STARTS AGAIN, IT DOESN'T HAVE THE EXHAUST ORIGINAL I ADAPTED ANOTHER, FROM A TSURO, I SCANNED IT IN AUTO ZONE AND IT INDICATED NAL OPERATION IN THE SENSOR CIRCUIT OF 02 (BANK 1 SENSOR 1). WHAT COULD BE THE FAULT