P02F7 Cylinder # 10 Injector Circuit Out of Range / Performance

Content

P02F7 Cylinder # 10 Injector Circuit Out of Range / Performance

OBD-II DTC Datasheet

Cylinder No. 10 injector circuit out of range / performance

What does this mean?

OBD DTC P02F7 is a generic transmission code common to all vehicles. Although the code is the same, the repair procedure may vary slightly depending on the manufacturer.

This code means the powertrain control module (PCM) experienced an out of range or performance problem with the # 10 fuel injector in ignition order.

In short, this fuel injector is malfunctioning for one of a variety of reasons. It is important to diagnose and fix this type of problem as soon as possible. When the fuel injector is faulty, it will cause ripples on the line, which means engine operating parameters change due to mixed signals in the PCM.

This type of problem is best addressed as soon as possible to prevent damage to other internal components. A faulty fuel injector will affect the spark plug, cause knocking, affect the oxygen sensor and catalytic converter, and some other components.

Refer to your specific vehicle repair manual to determine the location of the # 10 cylinder for your specific application.

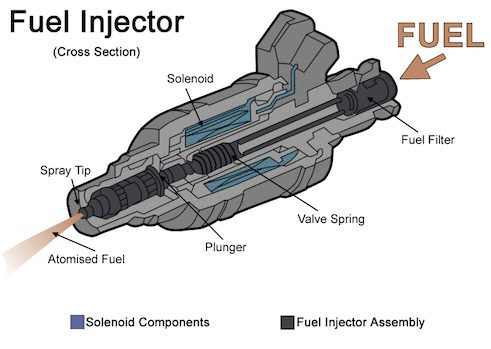

Cross section of a typical automotive fuel injector (courtesy of WikipedianProlific):

symptoms

Symptoms displayed for a P02F7 code may include:

- The check engine light will come on and a P02F7 code will be set.

- The engine will run more roughly than usual.

- Lack of power

- This can lead to a significant reduction in fuel consumption.

reasons

Possible causes of this DTC:

- Dirty fuel injector feeding cylinder number two

- Defective fuel injector

- Clogged fuel injector

- Open or short circuit in the fuel injector harness

- Faulty electrical harness from PCM to injector

- Defective electrical connector on the fuel injector.

- Loose or corroded fuel injector connector

P02F7 Diagnosis / Repair

Typically, this type of problem is associated with a loose or corroded electrical connector on an injector, a dirty injector (dirty or clogged), or a faulty injector that needs to be replaced.

For over 45 years, I have found that loose or corroded connectors have been the cause of electrical problems most of the time. I have only found a few instances where low voltage wiring shorted or opened (when not touched).

Most of the electrical problems were related to the alternator, starter solenoid wiring, oxygen sensor wiring due to close proximity to the exhaust system, and the battery. Most of the electrical work involved fixing customer-installed items such as high-power stereos and other parts or equipment that were incorrectly installed.

The fuel injectors are powered by the fuel pump relay. The PCM activates the relay when the key is turned on. This means that as long as the key is on, the injectors are powered.

The PCM activates the injector by supplying ground at the right time and for the right time.

- Check the connector on the fuel injector. It is a plastic connector attached to the injector with a wire clip around the connector. Pull on the connector to check if it detaches easily. Remove the wire clip and remove the connector from the injector.

- Inspect the harness connector for corrosion or extruded pins. Make sure the two blades are not bent in the injector itself. Repair any defect, apply dielectric grease and install the electrical connector.

- Start the engine and listen to the injector to make sure it works. Bring a long screwdriver to the injector and place the pen to your ear, and you can clearly hear the sound. If it does not emit a strongly audible click, then it is either not supplied with electricity, or it is faulty.

- If there is no click, remove the connector from the injector and check for the presence of power with a voltmeter. Lack of power means that the wiring to the fuel pump relay is faulty or poorly connected. If it has power, check both pins on the harness connector and if the PCM injector driver is working, the voltmeter will show fast pulses. If pulses are visible, replace the injector.

- If the nozzle worked, then it is clogged or dirty. Try to clear it first. The nozzle flush kit is inexpensive and will come in handy for the rest of the nozzles, possibly preventing repetition. If flushing does not solve the problem, the injector must be replaced.

Buy a “direct” nozzle flush kit online or at an auto parts store. It will consist of a high pressure injector cleaner bottle and a hose with an end to which the injector cleaner bottle can be screwed.

- Pull out the fuse to the fuel pump.

- Start the car and let it run until it dies due to lack of fuel.

- Remove and plug the fuel return line attached to the fuel pressure regulator. This is to prevent the vacuum cleaner from returning to the fuel tank.

- Remove the Schrader valve in the fuel rail inspection hole. Connect the flush kit fuel line to this test port. Thread the high pressure fuel injection cleaner bottle onto the flush kit fuel line.

- Start the engine and let it run until it runs out of fuel. It will only work on a bottle of cleaner.

- When the engine dies, turn off the key, remove the flush kit line and replace the Schrader valve. Install the fuel pump fuse.

Related DTC discussions

- There are currently no related topics in our forums. Post a new topic on the forum now.

Need more help with the P02F7 code?

If you still need help with DTC P02F7, post a question in the comments below this article.

NOTE. This information is provided for informational purposes only. It is not intended to be used as a repair recommendation and we are not responsible for any action you take on any vehicle. All information on this site is protected by copyright.