P0335 Crankshaft Position Sensor Circuit Malfunction

Content

Trouble Code P0335 OBD-II Datasheet

Crankshaft Position Sensor Circuit Malfunction

What does this mean?

This Diagnostic Trouble Code (DTC) is a generic transmission code, which means it applies to OBD-II equipped vehicles. Although general, specific repair steps may differ depending on the brand / model.

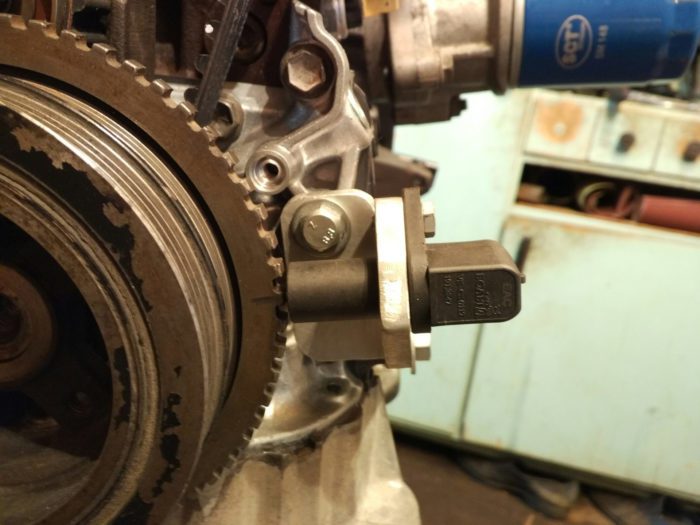

The Crankshaft Position (CKP) sensor measures the position of the crankshaft and transmits this information to the PCM (Powertrain Control Module).

Depending on the vehicle, the PCM uses this crankshaft position information to correctly determine spark timing or, in some systems, only to detect misfire and does not control ignition timing. The CKP sensor is stationary and works in conjunction with a reaction ring (or toothed ring) attached to the crankshaft. When this reactor ring passes in front of the CKP sensor, the magnetic field generated by the CKP sensor is interrupted and this creates a square-wave voltage signal that the PCM interprets as crankshaft position. If the PCM detects that there are no crankshaft pulses or if it sees a pulsing problem in the output circuit, P0335 will set.

Related Crankshaft Position Sensor DTCs:

- P0336 Crankshaft Position Sensor Circuit Range / Performance

- P0337 Low crankshaft position sensor input

- P0338 Crankshaft Position Sensor Circuit High Input

- P0339 Crankshaft Position Sensor Intermittent Circuit

Symptoms of error P0335

NOTE: If the crank sensor is only used to detect misfire and NOT to detect ignition timing (depending on the vehicle), the vehicle must start and operate with the MIL (malfunction indicator) lamp on. In addition, some vehicles require multiple key cycles to turn on the MIL. In this case, the MIL may be off until the problem becomes frequent enough over time. If the crank sensor is used for both misfire detection and ignition timing, the vehicle may or may not start. Symptoms may include:

- The car may not start (see above)

- Vehicle may move roughly or skip ignition

- Illumination MIL

- drop in engine performance

- unusual increase in fuel consumption

- some difficulty starting the engine

- MIL activation problem (malfunction indicator)

Causes of the P0335 code

This code appears when the engine control module (PCM) can no longer determine that the sensor is working properly based on its placement on the crankshaft. Indeed, the task of the crankshaft position sensor is to control the speed of rotation of the crankshaft. The PCM regulates fuel distribution by sensing the position of the crankshaft and camshaft position sensor. Interruption or erroneous transmission of these position signals will automatically set DTC P0355. This is because in the absence of this signal, the PCM detects a ripple problem in the output circuit.

The P0335 "check engine light" code can be caused by:

- Damaged CKP sensor connector

- The reactor ring is damaged (missing teeth or does not rotate due to shearing of the keyway)

- Sensor output open

- Sensor output is shorted to ground

- Sensor output shorted to voltage

- Defective crank sensor

- Timing belt break

- Unsuccessful PCM

Possible solutions

- Use a scan tool to check for a RPM signal with the engine running or cranking.

- If no RPM reading is available, inspect the crank sensor and connector for damage and repair if necessary. If there is no visible damage and you have access to the scope, you can check the 5 volt CKP rectangular diagram. If you do not, then get the resistance reading of your crank sensor from the repair manual. (There are so many different types of crank sensors that it is impossible to get the correct resistance reading here.) Then check the resistance of the CKP sensor by disconnecting the sensor and measuring the resistance of the sensor. (It is best to check the resistance reading on the PCM connector. This eliminates any wiring problems from the outset. But this requires some mechanical skill and should not be done unless you are familiar with automotive electrical systems). Is the sensor within the allowed resistance range?

- If not, replace the CKP sensor. If so, double-check the resistance reading at the PCM connector. Is reading still OK?

- If not, repair open or short circuit in the crankshaft sensor wiring and recheck. If the reading is OK, the problem is intermittent or the PCM may be defective. Try reconnecting and checking the speed signal again. If there is now a RPM signal, check the wiring harness to try to cause a malfunction.

This code is basically identical to P0385. This code P0335 refers to the crankshaft position sensor "A" while P0385 refers to the crankshaft position sensor "B". Other crank sensor codes include P0016, P0017, P0018, P0019, P0335, P0336, P0337, P0338, P0339, P0385, P0386, P0387, P0388, and P0389.

Repair Tips

Given the specifics of the problem, a correct diagnosis can usually only be made by a mechanic who will use special tools. After the car is taken to the workshop, the mechanic usually has to scan the data and codes contained in the PCM. Once this is done and after further checks have been made, a visual inspection of the sensor and its wiring can begin. With the help of a scan, the mechanic, by examining the engine speed data, will also be able to determine the exact point of the shaft affected by the malfunction.

Another possible solution is to carefully inspect the crankshaft sensor and connector to detect a possible malfunction.

If the problem is more simply related to a broken toothed belt or a damaged brake ring, it will be necessary to proceed with the replacement of these components, which are currently compromised. Finally, if the problem is due to a short in the wiring, then the damaged wires will need to be carefully replaced.

DTC P0335, which is associated with serious mechanical and electrical damage in the engine, which can cause problems when driving a car, should by no means be underestimated. Therefore, for safety reasons, it is recommended not to drive until this problem is resolved. In some cases, if you persist in driving, the engine may even lock up and not start: for this reason, diagnostics are mandatory.

Given the complexity of the diagnostic operation, requiring specialized equipment and very technical expertise, a DIY solution in a home garage is definitely not feasible. However, the first visual inspection of the camshaft and wiring can also be done by yourself.

It is difficult to estimate the upcoming costs, since a lot depends on the results of the diagnostics carried out by the mechanic. On average, replacing a crankshaft position sensor in a workshop can cost even more than 200 euros.

Frequently Asked Questions (FAQ)

What does code P0355 mean?

DTC P0355 indicates a malfunction in the crankshaft position sensor circuit.

What causes the P0355 code?

A faulty electrical connection, a wiring problem, or a malfunction of the encoder itself are the most common causes of this DTC.

How to fix code P0355?

Carry out a thorough check of all elements connected to the encoder.

Can code P0355 go away on its own?

Unfortunately no. In this case, intervention is necessary.

Can I drive with code P0355?

Driving a car with this code is strongly discouraged.

How much does it cost to fix code P0355?

On average, replacing a crankshaft position sensor in a workshop can even cost over 200 euros.

Need more help with your p0335 code?

If you still need help with DTC P0335, post a question in the comments below this article.

NOTE. This information is provided for informational purposes only. It is not intended to be used as a repair recommendation and we are not responsible for any action you take on any vehicle. All information on this site is protected by copyright.

3 comment

marlene

good evening my nissan navara d40 has a problem P0335 which is displayed what to do? on the other hand it starts and continues to turn even without the crankshaft sensor…. I don't understand thank you for your answer

Emo

Good evening, is it possible if the sensor is oiled and the washer lubricated, this error occurs on a peugeot 407 1.6 hdi

Emo

Good evening, is it possible if the sensor is oiled and the washer lubricated, this error occurs at Peugeot