P060F Internal coolant temperature control module

Content

- P060F Internal coolant temperature control module

- OBD-II DTC Datasheet

- What does this mean?

- What is the severity of this DTC?

- What are some of the symptoms of the code?

- What are some of the common causes for the code?

- What are some steps to troubleshoot the P060F?

- Related DTC discussions

- Need more help with your P060F code?

P060F Internal coolant temperature control module

OBD-II DTC Datasheet

Internal Control Module Coolant Temperature Characteristics

What does this mean?

This Generic Powertrain Diagnostic Trouble Code (DTC) is commonly applied to many OBD-II vehicles. This may include but is not limited to Mazda, Ford, Honda, Chevrolet, Jeep, Dodge, etc.

When a P060F code persists, it means the powertrain control module (PCM) has detected an internal performance error in the ECT circuit. Other controllers may also detect an internal PCM performance error (in the ECT sensor circuit) and contribute to maintaining the P060F.

The internal control module monitoring processors are responsible for the various controller self-testing functions and the overall accountability of the internal control module. The ECT sensor inputs and outputs are self-tested and monitored continuously by the PCM and other relevant controllers. The transmission control module (TCM), traction control module (TCSM), and other controllers can communicate with the ECT sensor.

ECT sensors consist of a thermistor immersed in hard resin and housed in a metal or plastic case. Brass is the most common metal used as an ECT sensor body material. The ECT housing is designed to be screwed into a coolant passage in an engine intake manifold, cylinder head or block. As warm coolant flows through the passages and through the ECT sensor, the level of thermal resistance in the ECT sensor decreases. When the engine coolant temperature decreases, the resistance increases and as a result, the voltage of the ECT sensor circuit decreases. These resistance fluctuations (which result in voltage fluctuations in the circuit) are interpreted by the PCM as changes in engine coolant temperature. The ECT sensor input is critical in calculating the fuel delivery and ignition timing strategy.

Whenever the ignition is turned on and the PCM is energized, an internal self-test of the ECT circuit is initiated. In addition to performing a self-test on the internal controller, the Controller Area Network (CAN) also compares the signals from each individual module to ensure that all controllers are working as expected. These tests are performed at the same time.

If the PCM detects a mismatch between any of the onboard controllers that indicates an internal ECT sensor error, a P060F code will be stored and a malfunction indicator lamp (MIL) may illuminate. It may take several failure cycles to illuminate the MIL, depending on the perceived severity of the malfunction.

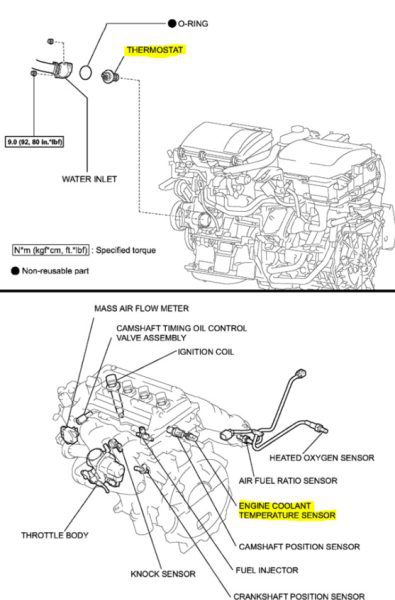

Photo of the PKM with the cover removed:

What is the severity of this DTC?

Internal Control Module processor codes are to be classified as Severe. A stored P060F code can suddenly and without warning lead to severe handling and fuel efficiency problems.

What are some of the symptoms of the code?

Symptoms of a P060F trouble code may include:

- Handling issues (especially at startup)

- Abrupt or erratic automatic transmission shifts

- Decreased fuel efficiency

- Rough idle or stalls (especially idling)

- Oscillation on acceleration

What are some of the common causes for the code?

- Reasons for this code may include:

- Faulty controller or programming error

- Open or short circuit in the circuit or connectors in the CAN harness

- Insufficient grounding of the control module

- Defective ECT sensor

- Corroded Electrical Connector (ECT)

- Open or short circuit in a chain between the ECT sensor and the PCM

What are some steps to troubleshoot the P060F?

Even for the most experienced and well-equipped professional, diagnosing the P060F code can be challenging. There is also the problem of reprogramming. Without the necessary reprogramming equipment, it will be impossible to replace the faulty controller and carry out a successful repair.

If there are ECM / PCM power supply codes, they obviously need to be corrected before attempting to diagnose the P060F. In addition, if ECT sensor codes are present, they must first be diagnosed and repaired.

There are some preliminary tests that can be performed before an individual controller is declared faulty. You will need a diagnostic scanner, a digital volt-ohmmeter (DVOM) and a source of reliable information about the vehicle. An infrared thermometer with a laser pointer may come in handy.

Connect the scanner to the vehicle diagnostic port and get all stored codes and freeze frame data. You will want to write this information down just in case the code turns out to be intermittent. After recording all relevant information, clear the codes and test drive the vehicle until the code is cleared or the PCM enters ready mode. If the PCM enters ready mode, the code is intermittent and harder to diagnose. The condition that caused the P060F to be stored may even get worse before a diagnosis can be made. If the code is reset, continue with this short list of pre-tests.

When trying to diagnose P060F, information can be your best tool. Search your vehicle information source for technical service bulletins (TSBs) that match the stored code, vehicle (year, make, model, and engine) and symptoms displayed. If you find the correct TSB, it can provide diagnostic information that will help you to a great extent.

Use your vehicle information source to obtain connector views, connector pinouts, component locators, wiring diagrams, and diagnostic block diagrams relevant to the code and vehicle in question.

Use the DVOM to test the fuses and relays of the controller power supply. Check and replace blown fuses if necessary. Fuses should be checked with a loaded circuit.

If all fuses and relays are working properly, a visual inspection of the wiring and harnesses associated with the controller should be performed. You will also want to check the chassis and motor ground connections. Use your vehicle information source to obtain grounding locations for associated circuits. Use DVOM to check ground integrity.

Visually inspect the system controllers for damage caused by water, heat, or collision. Any controller damaged, especially by water, is considered defective.

If the power and ground circuits of the controller are intact, suspect a faulty controller or a controller programming error. Replacing the controller will require reprogramming. In some cases, you can purchase reprogrammed controllers from the aftermarket. Other vehicles / controllers will require onboard reprogramming, which can only be done through a dealership or other qualified source.

Checking the sensor and ECT circuits

Any stored code associated with the ECT sensor needs to be checked to make sure the engine is not overheating. It must be filled with coolant and operate within the permissible temperature range.

Check the reference circuit of the ECT sensor connector using the positive test lead from the DVOM. Use the negative test lead to test the ground pin.

Key on and engine off (KOEO) check for a reference voltage (typically 5V) and ground at the ECT sensor connector.

If both reference voltage and ground are present at their respective connector pins, insert the sensor connector. Test the signal circuit of the ECT sensor with the positive test lead DVOM (the negative sensor is connected to a known good engine ground). Use an infrared thermometer to check the actual coolant temperature. Check out the temperature versus voltage diagram (found in the vehicle information source). With it, you can determine if the ECT sensor is working properly by comparing the actual voltage with the desired voltage.

If the ECT sensor does not display the correct voltage value (based on the actual coolant temperature), suspect it is faulty.

If the ECT sensor signal circuit is displaying the correct voltage level, use the DVOM to test the signal circuit at the PCM connector. If there is no sensor signal at the PCM connector, but it is detected at the sensor connector, there is an open circuit between the two components.

- Unlike most other codes, P060F is likely caused by a faulty controller or a controller programming error.

- Check the system ground for continuity by connecting the negative test lead of the DVOM to ground and the positive test lead to the battery voltage.

Related DTC discussions

- There are currently no related topics in our forums. Post a new topic on the forum now.

Need more help with your P060F code?

If you still need help with the P060F error code, post a question in the comments below this article.

NOTE. This information is provided for informational purposes only. It is not intended to be used as a repair recommendation and we are not responsible for any action you take on any vehicle. All information on this site is protected by copyright.