P20A4 Reductant purge control valve stuck open

Content

- P20A4 Reductant purge control valve stuck open

- OBD-II DTC Datasheet

- What does this mean?

- What is the severity of this DTC?

- What are some of the symptoms of the code?

- What are some of the common causes for the code?

- What are the P20A4 troubleshooting steps?

- What are the standard ways to fix this code?

- Related DTC discussions

- Need more help with the P20A4 code?

P20A4 Reductant purge control valve stuck open

OBD-II DTC Datasheet

Reductant purge control valve stuck open

What does this mean?

This is a generic powertrain diagnostic trouble code (DTC) that applies to many OBD-II diesel vehicles (1996 to present). This may include, but is not limited to, Chevrolet, GMC, Ford, Mitsubishi, VW, Sprinter, Audi, etc. Despite the general nature, the exact repair steps may vary depending on the model year, make, model and transmission configuration.

OBD-II DTC P20A4 and associated codes P20A0, P20A1, P20A2, P20A3, and P20A5 are associated with the reductant purge control valve circuit. This circuit is also known as Diesel Exhaust Liquid (DEF).

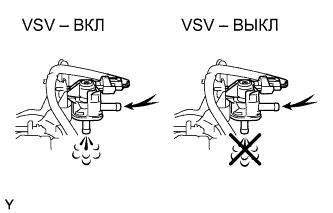

The purpose of the reductant purge valve circuitry is to send a signal to the power control module (PCM) or engine control module (ECM) as a reference point to determine when the reductant pump needs to reverse flow and purge the DEF system. This process is used to help convert leftover exhaust particles into harmless gases. The DEF system is designed to convert harmful NOx gases into nitrogen, carbon dioxide and water to protect the environment.

When the PCM or ECM detects that the reductant purge control valve is stuck open, code P20A4 will set and the check engine light will illuminate.

Mechanic:

What is the severity of this DTC?

The severity of this code is usually moderate, but P20A4 can be serious if harmful gases are removed from the exhaust, making it a safety issue that requires immediate attention.

What are some of the symptoms of the code?

Symptoms of a P20A4 trouble code may include:

- Poor engine performance

- Reduced fuel economy

- Check engine light is on

What are some of the common causes for the code?

Reasons for this P20A4 code may include:

- Reducing agent purge control valve defective

- Faulty or damaged wiring

- Loose or defective control module ground strap

- Corroded, damaged or loose connector

- Defective fuse or jumper (if applicable)

- Defective PCM or ECM

What are the P20A4 troubleshooting steps?

The first step in troubleshooting any problem is to review the vehicle-specific Technical Service Bulletins (TSBs) by year, model, and powerplant. In some cases, this can save you a lot of time in the long run by pointing you in the right direction.

The second step is to locate all components associated with the reductant purge control valve circuit and look for obvious physical damage. Depending on the specific vehicle, the DEF system may include several components including an electric reductant pump, purge valve, pressure sensor, integral level sensor, temperature sensor, system heaters, filters, electrically controlled reductant injector, and reservoir. Perform a thorough visual inspection to check the associated wiring for obvious defects such as scratches, abrasions, exposed wires, or burn marks. Next, check the connectors and connections for security, corrosion and damage to the contacts. This process should include all wiring connectors and connections to all components including the PCM or ECM. Consult the specific technical data sheet for the vehicle to see if a fuse or a fuse link is included in the circuit.

Advanced steps

The additional steps become very vehicle specific and require appropriate advanced equipment to be performed accurately. These procedures require a digital multimeter and vehicle-specific technical reference documents. In this situation, a pressure gauge may also be required to facilitate the troubleshooting process.

Voltage test

The reference voltage and allowable ranges may vary depending on the specific vehicle and circuit configuration. Specific technical data will include troubleshooting tables and appropriate sequence of steps to help you make an accurate diagnosis.

If this process detects that a power source or ground is missing, a continuity check may be required to verify the integrity of wiring, connectors, and other components. Continuity tests should always be done with power disconnected from the circuit, and normal readings for wiring and connections should be 0 ohms of resistance. Resistance or no continuity indicates faulty wiring that is open or shorted and requires repair or replacement. Continuity testing from the PCM or ECM to the frame will confirm the integrity of the ground straps and ground wires. Resistance indicates a loose connection or possible corrosion.

What are the standard ways to fix this code?

- Replacing the Reductant Purge Control Valve

- Cleaning connectors from corrosion

- Repair or replace faulty wiring

- Replacing a blown fuse or fuse (if applicable)

- Repair or replacement of faulty grounding tapes

- Flashing or replacing PCM or ECM

General error

- Replacing a reductant purge control valve, associated DEF, PCM, or ECM when faulty wiring causes this code to set.

Hopefully the information in this article has helped point you in the right direction to troubleshoot a reductant purge control valve circuit DTC problem. This article is for informational purposes only and specific technical data and service bulletins for your vehicle should always take priority.

Related DTC discussions

- There are currently no related topics in our forums. Post a new topic on the forum now.

Need more help with the P20A4 code?

If you still need help with DTC P20A4, post a question in the comments below this article.

NOTE. This information is provided for informational purposes only. It is not intended to be used as a repair recommendation and we are not responsible for any action you take on any vehicle. All information on this site is protected by copyright.