Processing of chemical energy sources

Content

A common situation in every home is that recently purchased batteries are no longer good. Or maybe, taking care of the environment, and at the same time - about the wealth of our wallet, we got batteries? After a while, they will also refuse to cooperate. So in the trash? Absolutely not! Knowing about the threats that cells cause in the environment, we will look for a rally point.

Collection

What is the scale of the problem we are dealing with? A 2011 report by the Chief Environmental Inspector indicated that more than 400 million cells and batteries. Approximately the same number committed suicide.

Rice. 1. Average composition of raw materials (used cells) from state collections.

So we need to develop about 92 thousand tons of hazardous waste containing heavy metals (mercury, cadmium, nickel, silver, lead) and a number of chemical compounds (potassium hydroxide, ammonium chloride, manganese dioxide, sulfuric acid) (Fig. 1). When we throw them away - after the coating has corroded - they pollute the soil and water (Fig. 2). Let's not make such a "gift" to the environment, and therefore to ourselves. Of this amount, 34% was accounted for by specialized processors. Therefore, there is still much to be done, and it is not a consolation that it is not only in Poland?

Rice. 2. Corroded cell coatings.

We no longer have an excuse for nowhere to go used cells. Every outlet that sells batteries and replacements is required to accept them from us (as well as old electronics and household appliances). Also, many shops and schools have containers in which we can put cages. So let's not "disclaim" and not throw away used batteries and accumulators in the trash. With a little desire, we will find a rally point, and the links themselves weigh so little that the link will not tire us.

Sorting

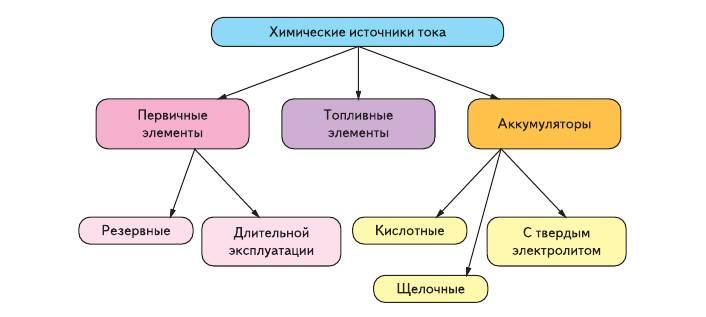

As with others recyclable materials, the efficient transformation makes sense after sorting. Waste from industrial plants is usually uniform in quality, but waste from public collections is a mixture of available cell types. Thus, the key question becomes segregation.

In Poland, sorting is done manually, while other European countries already have automated sorting lines. They use sieves with appropriate mesh sizes (allowing separation of cells of different sizes) and x-ray (content sorting). The composition of raw materials from collections in Poland is also slightly different.

Until recently, our classic acidic Leclanche cells dominated. It is only recently that the advantage of the more modern alkaline elements, which conquered the Western markets many years ago, has become noticeable. In any case, both types of disposable cells account for more than 90% of the collected batteries. The rest is button batteries (powering watches (Fig. 3) or calculators), rechargeable batteries and lithium batteries for phones and laptops. The reason for such a small share is the higher price and longer service life compared to disposable elements.

Rice. 3. Silver link used to power wrist watches.

Performing the shaping

After the breakup, it's time for the most important thing processing stage - recovery of raw materials. For each type, the products received will be slightly different. However, the processing techniques are similar.

mechanical processing consists in grinding waste in mills. The resulting fractions are separated using electromagnets (iron and its alloys) and special sieve systems (other metals, plastic elements, paper, etc.). Flooded the method lies in the fact that there is no need to carefully sort the raw materials before processing, defect - a large amount of unusable waste that requires disposal in landfills.

Hydrometallurgical recycling is the dissolution of cells in acids or bases. At the next stage of processing, the resulting solutions are purified and separated, for example, metal salts, to obtain pure elements. Big advantage the method is characterized by low energy consumption and a small amount of waste requiring disposal. Defect This recycling method requires careful sorting of the batteries to avoid contamination of the resulting products.

Thermal processing consists in firing the cells in ovens of the appropriate design. As a result, their oxides are melted and obtained (raw materials for steel mills). Flooded method consists in the possibility of using unsorted batteries, defect and – energy consumption and generation of harmful combustion products.

but recyclable The cells are stored in landfills after preliminary protection against the ingress of their components into the environment. However, this is only a half measure, postponing the need to deal with this type of waste and the waste of many valuable raw materials.

We can also restore some of the nutrients in our home lab. These are the components of the classic Leclanche elements - high-purity zinc from the cups surrounding the element, and graphite electrodes. Alternatively, we can separate the manganese dioxide from the mixture within the mixture - simply boil it with water (to remove soluble impurities, mainly ammonium chloride) and filter. The insoluble residue (contaminated with coal dust) is suitable for most reactions involving MnO.2.

But not only the elements used to power household appliances are recyclable. Old car batteries are also a source of raw materials. Lead is extracted from them, which is then used in the manufacture of new devices, and the cases and the electrolyte filling them are disposed of.

No one needs to be reminded of the environmental damage that can be caused by toxic heavy metal and sulfuric acid solution. For our rapidly developing technical civilization, the example of cells and batteries is a model. An increasing problem is not the production of the product itself, but its disposal after use. I hope that the readers of the "Young Technician" magazine will inspire others to recycle by their example.

Experiment 1 - lithium battery

lithium cells they are used in calculators and to maintain power to the BIOS of computer motherboards (Fig. 4). Let us confirm the presence of metallic lithium in them.

Rice. 4. A lithium-manganese cell used to maintain power to the BIOS of a computer motherboard.

After disassembling the element (for example, the common type CR2032), we can see the details of the structure (Fig. 5): black compressed layer of manganese dioxide MnO2, a porous separator electrode impregnated with an organic electrolyte solution, insulating a plastic ring and two metal parts forming a housing.

Rice. 5. Components of a lithium-manganese cell: 1. The lower part of the body with a layer of lithium metal (negative electrode). 2. Separator impregnated with an organic electrolyte solution. 3. Pressed layer of manganese dioxide (positive electrode). 4. Plastic ring (electrode insulator). 5. Upper housing (positive electrode terminal).

The smaller one (the negative electrode) is covered with a layer of lithium, which quickly darkens in air. The element is identified by a flame test. To do this, take some soft metal on the end of the iron wire and insert the sample into the burner flame - the carmine color indicates the presence of lithium (Fig. 6). We dispose of metal residues by dissolving them in water.

Rice. 6. A sample of lithium in a burner flame.

Place a metal electrode with a layer of lithium in a beaker and pour a few cm3 water. A violent reaction occurs in the vessel, accompanied by the release of hydrogen gas:

Lithium hydroxide is a strong base and we can easily test it with indicator paper.

Experience 2 - alkaline bond

Cut out a disposable alkaline element, for example, type LR6 (“finger”, AA). After opening the metal cup, the internal structure is visible (Fig. 7): inside there is a light mass forming an anode (potassium or sodium hydroxide and zinc dust), and a dark layer of manganese dioxide MnO surrounding it.2 with graphite dust (cell cathode).

Rice. 7. Alkaline reaction of the anode mass in an alkaline cell. Visible cellular structure: light anode-forming mass (KOH + zinc dust) and dark manganese dioxide with graphite dust as a cathode.

The electrodes are separated from each other by a paper diaphragm. Apply a small amount of light substance to the test strip and moisten it with a drop of water. The blue color indicates the alkaline reaction of the anode mass. The type of hydroxide used is best verified by a flame test. A sample the size of several poppy seeds is glued to an iron wire soaked in water and placed in a burner flame.

Yellow color indicates the use of sodium hydroxide by the manufacturer, and pink-purple color indicates potassium hydroxide. Since sodium compounds contaminate almost all substances, and the flame test for this element is extremely sensitive, the yellow color of the flame can mask the spectral lines of potassium. The solution is to look at the flame through a blue-violet filter, which can be cobalt glass or a dye solution in the flask (indigo or methyl violet found in the wound disinfectant, pyoctane). The filter will absorb the yellow color, allowing you to confirm the presence of potassium in the sample.

Designation codes

To facilitate cell type identification, a special alphanumeric code has been introduced. For the most common types in our homes, it looks like: number-letter-letter-number, where:

- the first digit is the number of cells; ignored for single cells.

– the first letter indicates the cell type. When absent, it is a Leclanche zinc-graphite cell (anode: zinc, electrolyte: ammonium chloride, NH4Cl, zinc chloride ZnCl2, cathode: manganese dioxide MnO2). Other cell types are labeled as follows (the cheaper sodium hydroxide is also used instead of potassium hydroxide):

A, P – zinc-air elements (anode: zinc, atmospheric oxygen is reduced on a graphite cathode);

B, C, E, F, G - lithium cells (anode: lithium, but many substances are used as cathodes and electrolyte);

H – Ni-MH nickel-metal hydride battery (metal hydride, KOH, NiOOH);

K – Ni-Cd nickel-cadmium battery (cadmium, KOH, NiOOH);

L – alkaline element (zinc, KOH, MnO2);

M – mercury element (zinc, KOH; HgO), no longer used;

S – silver element (zinc, KOH; Ag2ABOUT);

Z – nickel-manganese element (zinc, KOH, NiOOH, MnO2).

- the following letter indicates the shape of the link:

F - lamellar;

R - cylindrical;

S - rectangular;

P – the current designation of cells with shapes other than cylindrical.

– the final figure or figures indicate the size of the reference (catalog values or directly giving dimensions).

Examples of marking:

R03

- a zinc-graphite cell the size of a little finger. Another designation is AAA or micro.

LR6 - an alkaline cell the size of a finger. Another designation is AA or minion.

HR14 – Ni-MH battery, the letter C is also used for size.

KR20 – Ni-Cd battery, the size of which is also marked with the letter D.

3LR12 - a flat battery with a voltage of 4,5 V, consisting of three alkaline cells.

6F22 – 9V battery; six individual planar zinc-graphite cells are enclosed in a rectangular case.

CR2032 – lithium-manganese cell (lithium, organic electrolyte, MnO2) with a diameter of 20 mm and a thickness of 3,2 mm.