Plastics in the world

Content

In 2050, the weight of plastic waste in the oceans will exceed the weight of fish combined! Such a warning was included in a report by the Ellen MacArthur Foundation and McKinsey published on the occasion of the World Economic Forum in Davos in 2016.

As we read in the document, the ratio of tons of plastic to tons of fish in ocean waters in 2014 was one to five. In 2025, there will be one in three, and in 2050 there will be more plastic waste ... The report was based on interviews with more than 180 experts and an analysis of more than two hundred other studies. The authors of the report note that only 14% of plastic packaging is recycled. For other materials, the recycling rate remains much higher, recovering 58% of paper and up to 90% of iron and steel.

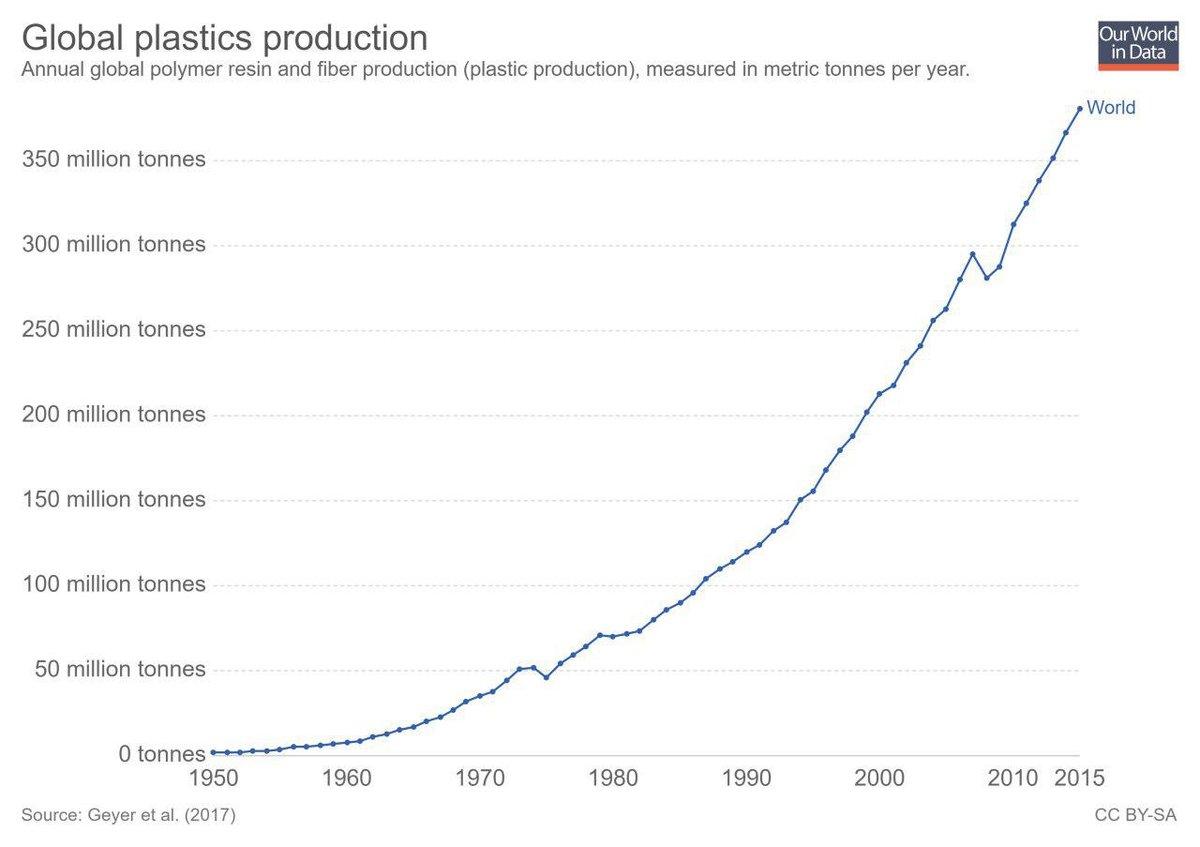

1. World production of plastics in 1950-2010

Thanks to its ease of use, versatility and quite obviously, it has become one of the most popular materials in the world. Its use increased nearly two hundredfold from 1950 to 2000 (1) and is expected to double in the next twenty years.

2. Picture from the Pacific paradise of the Tuvalu archipelago

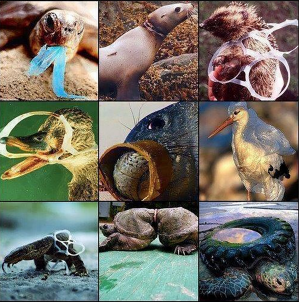

. We find it in bottles, foil, window frames, clothing, coffee machines, cars, computers, and cages. Even a football turf hides synthetic fibers between natural blades of grass. Plastic bags and bags sometimes accidentally eaten by animals are littered on roadsides and in fields (2). Often, due to the lack of alternatives, plastic waste is burned, releasing toxic fumes into the atmosphere. Plastic waste clogs sewers, causing floods. They prevent the germination of plants and the absorption of rainwater.

3. Turtle eats plastic foil

The smallest things are the worst

Many researchers note that the most dangerous plastic waste is not PET bottles floating in the ocean or billions of collapsing plastic bags. The biggest problem is objects that we don't really notice. These are thin plastic fibers woven into the fabric of our clothes. Dozens of ways, hundreds of roads, through sewers, rivers, even through the atmosphere, they penetrate into the environment, into the food chains of animals and humans. The harmfulness of this type of pollution reaches level of cellular structures and DNA!

Unfortunately, the clothing industry, which is estimated to process around 70 billion tons of this type of fiber into 150 billion pieces of clothing, is actually not regulated in any way. Clothing manufacturers are not subject to such strict restrictions and controls as plastic packaging or the aforementioned PET bottles. Little is said or written about their contribution to the plastic pollution of the world. There are also no strict and well-established procedures for the disposal of clothing intertwined with harmful fibers.

A related and no less problem is the so-called microporous plastic, that is, tiny synthetic particles less than 5 mm in size. The granules come from many sources - plastics that break down in the environment, in the production of plastics, or in the process of abrasion of car tires during their operation. Thanks to the support of the cleansing action, microplastic particles can even be found in toothpastes, shower gels and peeling products. With sewage, they enter rivers and seas. Most conventional sewage treatment plants cannot catch them.

An alarming disappearance of waste

After a 2010-2011 study by a marine expedition called Malaspina, it was unexpectedly found that there was significantly less plastic waste in the oceans than thought. For months. Scientists were counting on a catch that would estimate the amount of ocean plastic in the millions of tons. Meanwhile, a study report that appeared in the journal Proceedings of the National Academy of Sciences in 2014 talks about… 40. tone. Scientists have found that 99% of the plastic that should float in ocean waters is missing!

4. Plastic and animals

Everything is fine? Absolutely not. Scientists speculate that the missing plastic has entered the ocean food chain. So: garbage is massively eaten by fish and other marine organisms. This happens after fragmentation due to the action of the sun and waves. Then tiny floating pieces of fish can be confused with their food - tiny sea creatures. The consequences of eating small pieces of plastic and other contact with plastic are not yet well understood, but it is probably not a good effect (4).

According to conservative estimates published in the journal Science, more than 4,8 million tons of plastic waste enters the oceans every year. However, it can reach 12,7 million tons. The scientists behind the calculations say that if the average of their estimate was about 8 million tons, that amount of debris would cover 34 Manhattan-sized islands in a single layer.

The main authors of these calculations are scientists from the University of California at Santa Barbara. In the course of their work, they collaborated with US federal agencies and other universities. An interesting fact is that according to these estimates, only from 6350 to 245 thousand. tons of plastic littering the sea float on the surface of ocean waters. The rest are elsewhere. According to scientists, both on the seabed and on the coasts and, of course, in animal organisms.

We have even newer and even more terrifying data. Late last year, Plos One, an online repository of scientific materials, published a collaborative paper by researchers from many hundreds of scientific centers who estimated the total mass of plastic waste floating on the surface of the world's oceans at 268 tons! Their assessment is based on data from 940 expeditions undertaken in 24-2007. in tropical waters and the Mediterranean.

"Continents" (5) of plastic waste are not static. Based on simulation movement of water currents in the oceans, scientists were able to determine that they do not gather in one place - rather, they are transported over long distances. As a result of the action of the wind on the surface of the oceans and the rotation of the Earth (through the so-called Coriolis force), water vortices are formed in the five largest bodies of our planet - i.e. the North and South Pacific, the North and South Atlantic and the Indian Ocean, where all floating plastic objects and waste gradually accumulate. This situation is cyclically repeated every year.

5. Map of the distribution of plastic debris in the ocean of different sizes.

Familiarity with the migration routes of these "continents" is the result of long simulations using specialized equipment (usually useful in climate research). The path followed by several million plastic waste has been studied. Modeling showed that in structures built over an area of several hundred thousand kilometers, water flows were present, taking part of the waste beyond their highest concentration and directing it to the east. Of course, there are other factors such as wave and wind strength that were not taken into account when preparing the above study, but certainly play a significant role in the speed and direction of plastic transportation.

These drifting waste "lands" are also an excellent vehicle for various types of viruses and bacteria, which can thus spread more easily.

How to clean up "garbage continents"

Can be collected by hand. Plastic waste is a curse for some, and a source of income for others. they are even coordinated by international organizations. Third World Collectors separate plastic at home. They work by hand or with simple machines. Plastics are shredded or cut into small pieces and sold for further processing. Intermediaries between them, the administration and public organizations are specialized organizations. This cooperation provides collectors with a stable income. At the same time, it is a way to remove plastic waste from the environment.

However, manual collection is relatively inefficient. Therefore, there are ideas for more ambitious activities. For example, the Dutch company Boyan Slat, as part of The Ocean Cleanup project, offers installation of floating garbage interceptors in the sea.

A pilot waste collection facility near Tsushima Island, located between Japan and Korea, has been very successful. It is not powered by any external energy sources. Its use is based on knowledge of the effects of wind, sea currents and waves. Floating plastic debris, caught in a trap curved in the form of an arc or slot (6), is pushed further into the area where it accumulates and can be removed relatively easily. Now that the solution has been tested on a smaller scale, larger installations, even a hundred kilometers long, will have to be built.

6. Collection of floating plastic waste as part of The Ocean Cleanup project.

Famous inventor and millionaire James Dyson developed the project a few years ago. MV Recycloneor great barge vacuum cleanerwhose task will be to clean the ocean waters of garbage, mostly plastic. The machine must catch debris with a net and then suck it up with four centrifugal vacuum cleaners. The concept is that suction should take place out of the water and not endanger the fish. Dyson is an English industrial equipment designer, best known as the inventor of the bagless cyclone vacuum cleaner.

And what to do with this mass of rubbish, when you still have time to collect it? There is no shortage of ideas. For example, Canadian David Katz suggests creating a plastic jar ().

Waste would be a kind of currency here. They could be exchanged for money, clothes, food, mobile top-ups, or a 3D printer., which, in turn, allows you to create new household items from recycled plastic. The idea has even been implemented in Lima, the capital of Peru. Now Katz intends to interest the Haitian authorities in him.

Recycling works, but not everything

The term "plastic" means materials, the main component of which are synthetic, natural or modified polymers. Plastics can be obtained both from pure polymers and from polymers modified by the addition of various excipients. The term "plastics" in colloquial language also covers semi-finished products for processing and finished products, provided that they are made from materials that can be classified as plastics.

There are about twenty common types of plastic. Each one comes in numerous options to help you choose the best material for your application. There are five (or six) groups bulk plastics: polyethylene (PE, including high and low density, HD and LD), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS) and polyethylene terephthalate (PET). This so-called big five or six (7) covers almost 75% of European demand for all plastics and represents the largest group of plastics sent to municipal landfills.

Disposal of these substances by burning outdoors it is by no means accepted by both specialists and the general public. On the other hand, environmentally friendly incinerators can be used for this purpose, reducing waste by up to 90%.

Waste storage at landfills it's not as toxic as burning them outdoors, but it's no longer accepted in most developed countries. While it's not true that "plastic is durable," polymers take much longer to biodegrade than food, paper, or metal waste. Long enough that, for example, in Poland at the current level of production of plastic waste, which is about 70 kg per capita per year, and at a recovery rate that until recently barely exceeded 10%, the domestic pile of this garbage would reach 30 million tons in just over a decade.

Factors such as chemical environment, exposure (UV) and, of course, fragmentation of the material affect the slow decomposition of plastic. Many recycling technologies (8) simply rely on greatly accelerating these processes. As a result, we get simpler particles from polymers that we can turn back into material for something else, or smaller particles that can be used as raw materials for extrusion, or we can go to the chemical level - to obtain biomass, water, various types of gases, carbon dioxide, methane, nitrogen.

8. Recycling and plastics processing technologies

The way to dispose of thermoplastic waste is relatively simple, as it can be recycled many times. However, during processing, a partial degradation of the polymer occurs, resulting in a deterioration in the mechanical properties of the product. For this reason, only a certain percentage of recycled materials are added to the processing process, or the waste is processed into products with lower performance requirements, such as toys.

A much bigger problem when disposing of used thermoplastic products is the need to sort in terms of the range, which requires professional skills and the removal of impurities from them. This is not always beneficial. Plastics made from cross-linked polymers are in principle not recyclable.

All organic materials are flammable, but it is also difficult to destroy them in this way. This method cannot be used for materials containing sulphur, halogens and phosphorus, since when burned, they release into the atmosphere a large amount of toxic gases, which are the cause of the so-called acid rain.

First of all, organochlorine aromatic compounds are released, the toxicity of which is many times higher than potassium cyanide, and hydrocarbon oxides in the form of dioxanes - C4H8O2 i furanov - C4H4About the release into the atmosphere. They accumulate in the environment but are difficult to detect due to low concentrations. Being absorbed with food, air and water and accumulating in the body, they cause severe diseases, reduce the body's immunity, are carcinogenic and can cause genetic changes.

The main source of dioxin emissions is the incineration of waste containing chlorine. In order to avoid the release of these harmful compounds, installations equipped with so-called. afterburner, at min. 1200°C.

Waste is recycled in different ways

Technology recycling made of plastic is a multi-stage sequence. Let's start with the appropriate collection of sediment, that is, the separation of plastic from garbage. At the processing plant, first pre-sorting takes place, then grinding and grinding, separation of foreign bodies, then sorting of plastics by type, drying and obtaining a semi-finished product from recovered raw materials.

It is not always possible to sort the collected garbage by type. That is why they are sorted by many different methods, usually divided into mechanical and chemical. Mechanical methods include: manual segregation, flotation or pneumatic. If the waste is contaminated, such sorting is carried out in a wet way. Chemical methods include hydrolysis – steam decomposition of polymers (raw materials for the re-production of polyesters, polyamides, polyurethanes and polycarbonates) or low temperature pyrolysis, with which, for example, PET bottles and used tires are disposed of.

Under pyrolysis understand the thermal transformation of organic substances in an environment completely anoxic or with little or no oxygen. Low-temperature pyrolysis proceeds at a temperature of 450-700°C and leads to the formation of, among other things, pyrolysis gas, consisting of water vapor, hydrogen, methane, ethane, carbon monoxide and dioxide, as well as hydrogen sulfide and ammonia, oil, tar, water and organic matter, pyrolysis coke and dust with a high content of heavy metals. The installation does not require power supply, as it works on pyrolysis gas generated during the recirculation process.

Up to 15% of pyrolysis gas is consumed for the operation of the installation. The process also produces up to 30% pyrolysis liquid, similar to fuel oil, which can be divided into fractions such as: 30% gasoline, solvent, 50% fuel oil and 20% fuel oil.

The rest of the secondary raw materials obtained from one ton of waste are: up to 50% carbon pyrocarbonate is solid waste, in terms of calorific value close to coke, which can be used as solid fuel, activated carbon for filters or powdered as a pigment for paints and up to 5% metal (stern scrap) during the pyrolysis of car tires.

Houses, roads and fuel

The recycling methods described are serious industrial processes. They are not available in every situation. Danish engineering student Lisa Fuglsang Vestergaard (9) came up with an unusual idea while staying in the Indian city of Joygopalpur in West Bengal - why not make bricks that people could use to build houses from scattered bags and packages?

9. Lisa Fuglsang Westergaard

It was not just about making the bricks, but designing the whole process so that the people involved in the project would really benefit. According to her plan, the waste is first collected and, if necessary, cleaned. The collected material is then prepared by cutting it into smaller pieces with scissors or knives. The crushed raw material is put into a mold and placed on a solar grate where the plastic is heated. After about an hour, the plastic will melt, and after it cools down, you can remove the finished brick from the mold.

plastic bricks they have two holes through which bamboo sticks can be threaded, creating stable walls without the use of cement or other binders. Then such plastic walls can be plastered in the traditional way, for example, with a layer of clay that protects them from the sun. Houses made of plastic bricks also have the advantage that, unlike clay bricks, they are resistant, for example, to monsoon rains, which means they become much more durable.

It is worth remembering that plastic waste is also used in India. road construction. All road developers in the country are required to use plastic waste as well as bituminous mixtures in accordance with the government of India regulation of November 2015. This should help solve the growing problem of plastic recycling. This technology was developed by Prof. Rajagopalan Vasudevan of the Madurai School of Engineering.

The whole process is very simple. Waste is first crushed to a certain size using a special machine. They are then added to a properly prepared aggregate. The backfilled rubbish is mixed with hot asphalt. The road is laid at a temperature of 110 to 120°C.

There are many benefits to using waste plastic for road construction. The process is simple and does not require new equipment. For every kilogram of stone, 50 grams of asphalt is used. One tenth of this could be plastic waste, which reduces the amount of asphalt used. Plastic waste also improves surface quality.

Martin Olazar, an engineer at the University of the Basque Country, has built an interesting and possibly promising process line for processing waste into hydrocarbon fuels. The plant, which the inventor describes as mine refinery, is based on the pyrolysis of biofuel feedstocks for use in engines.

Olazar has built two types of production lines. The first one processes biomass. The second, more interesting one, is used to recycle plastic waste into materials that can be used, for example, in the production of tires. The waste is subjected to a rapid pyrolysis process in the reactor at a relatively low temperature of 500°C, which contributes to energy savings.

Despite new ideas and advances in recycling technology, only a small percentage of the 300 million tons of plastic waste produced worldwide each year is covered by it.

According to a study by the Ellen MacArthur Foundation, only 15% of packaging is sent to containers and only 5% is recycled. Nearly a third of plastics pollute the environment, where they will remain for decades, sometimes hundreds of years.

Let the garbage melt itself

Recycling of plastic waste is one of the directions. It is important, because we have already produced a lot of this rubbish, and a considerable part of the industry still supplies a lot of products from the materials of the big five multi-ton plastics. However over time, the economic importance of biodegradable plastics, new generation materials based, for example, on derivatives of starch, polylactic acid or ... silk, is likely to increase.

10. d2w biodegradable dog litter bags.

The production of these materials is still relatively expensive, as is usually the case with innovative solutions. However, the entire bill cannot be ignored as they exclude the costs associated with recycling and disposal.

One of the most interesting ideas in the field of biodegradable plastics is made from polyethylene, polypropylene and polystyrene, it seems to be a technology based on the use of various types of additives in their production, known by the conventions d2w (10) or FIR.

Better known, including in Poland, for several years now is the d2w product of the British company Symphony Environmental. It is an additive for the production of soft and semi-rigid plastics, from which we require fast, environmentally friendly self-degradation. Professionally, the d2w operation is called oxybiodegradation of plastics. This process involves the decomposition of the material into water, carbon dioxide, biomass and trace elements without other residues and without methane emission.

The generic name d2w refers to a range of chemicals added during the manufacturing process as additives to polyethylene, polypropylene and polystyrene. The so-called d2w prodegradant, which supports and accelerates the natural process of decomposition as a result of the influence of any selected factors that promote decomposition, such as temperature, sunlight, pressure, mechanical damage or simple stretching.

Chemical degradation of polyethylene, consisting of carbon and hydrogen atoms, occurs when the carbon-carbon bond is broken, which, in turn, reduces the molecular weight and leads to a loss of chain strength and durability. Thanks to d2w, the material degradation process has been reduced to even sixty days. Break time - which is important, for example, in packaging technology - it can be planned during the production of the material by appropriately controlling the content and types of additives. Once started, the degradation process will continue until the complete degradation of the product, whether it is deep underground, underwater or outdoors.

Studies have been done to confirm that self-disintegration from d2w is safe. Plastics containing d2w have already been tested in European laboratories. The Smithers/RAPRA laboratory has tested the suitability of d2w for food contact and has been used by major food retailers in England for several years. The additive has no toxic effect and is safe for the soil.

Of course, solutions such as d2w will not quickly replace the previously described recycling, but may gradually enter the recycling process. Eventually, a prodegradant can be added to the raw materials resulting from these processes, and we get an oxybiodegradable material.

The next step is plastics, which decompose without any industrial processes. Such, for example, as those of which ultra-thin electronic circuits are made, which dissolve after performing their function in the human body., presented for the first time in October last year.

Invention melting electronic circuits is part of a larger study of so-called fleeting - or, if you like, "temporary" - electronics () and materials that will disappear after completing their task. Scientists have already developed a method for constructing chips from extremely thin layers, called nanomembrane. They dissolve within a few days or weeks. The duration of this process is determined by the properties of the silk layer that covers the systems. Researchers have the ability to control these properties, i.e., by choosing the appropriate layer parameters, they decide how long it will remain a permanent protection for the system.

As explained by BBC Prof. Fiorenzo Omenetto of Tufts University in the US: “Soluble electronics work just as reliably as traditional circuits, melting to their destination in the environment they are in, at the time specified by the designer. It could be days or years."

According to prof. John Rogers of the University of Illinois, discovering the possibilities and applications of controlled dissolution materials is yet to come. Perhaps the most interesting prospects for this invention in the field of environmental waste disposal.

Will bacteria help?

Soluble plastics are one of the trends of the future, meaning a shift towards completely new materials. Secondly, look for ways to quickly decompose environmentally harmful substances that are already in the environment and it would be nice if they disappeared from there.

Most recently, The Kyoto Institute of Technology analyzed the degradation of several hundred plastic bottles. In the course of research, it was found that there is a bacterium that can decompose plastics. They called her . The discovery was described in the prestigious journal Science.

This creation uses two enzymes to remove the PET polymer. One triggers chemical reactions to break down molecules, the other helps release energy. The bacterium was found in one of 250 samples taken in the vicinity of a PET bottle recycling plant. It belonged to a group of microorganisms that decomposed the PET membrane surface at a rate of 130 mg/cm² per day at 30°C. Scientists also managed to obtain a similar set of microorganisms that do not possess, but are not able to metabolize PET. These studies showed that it did indeed biodegrade plastic.

In order to obtain energy from PET, the bacterium first hydrolyzes PET with an English enzyme (PET hydrolase) to mono(2-hydroxyethyl) terephthalic acid (MHET), which is then hydrolyzed in the next step using an English enzyme (MGET hydrolase). on the original plastic monomers: ethylene glycol and terephthalic acid. Bacteria can use these chemicals directly to produce energy (11).

11. PET degradation by bacteria

Unfortunately, it takes a full six weeks and the right conditions (including a temperature of 30°C) for an entire colony to unfold a thin piece of plastic. It doesn't change the fact that a discovery could change the face of recycling.

We are definitely not doomed to live with plastic trash scattered all over the place (12). As recent discoveries in the field of materials science show, we can get rid of bulky and hard-to-remove plastic forever. However, even if we soon switch to fully biodegradable plastic, we and our children will have to deal with leftovers for a long time to come. era of discarded plastic. Maybe this will be a good lesson for humanity, which will never give up technology without a second thought just because it is cheap and convenient?