Density of industrial oil

Content

The Role of Density in Lubricant Performance

Regardless of the ambient temperature, the density of all grades of industrial oils is less than the density of water. Since water and oil do not mix, if it is present in the container, oil droplets will float on the surface.

That's why if your car's lubrication system has a moisture problem, the water settles to the bottom of the sump and drains first whenever the plug is removed or the valve is opened.

The density of industrial oil is also important for the accuracy of calculations that are associated with the calculation of viscosity. In particular, when translating the dynamic viscosity index into the kinematic density of the oil, it must be known. And since the density of any low-viscosity medium is not a constant value, the viscosity can only be established with a known error.

This fluid property is critical to several lubricant properties. For example, as the density of a lubricant increases, the liquid becomes thicker. This leads to an increase in the time required for the particles to settle out of suspension. Most often, the main component in such a suspension are the smallest particles of rust. Rust density ranges from 4800…5600 kg/m3, so oil containing rust thickens. In tanks and other containers intended for temporary storage of oil, rust particles settle much more slowly. In any system where the laws of friction apply, this can cause failure, since such systems are very sensitive to any contamination. Therefore, if the particles are in suspension for longer, problems such as cavitation or corrosion can result.

Density of used industrial oil

Density deviations associated with the presence of foreign oil particles cause:

- Increased tendency to cavitation, both during suction and after passing through the oil lines.

- Increasing the power of the oil pump.

- Increased load on the moving parts of the pump.

- Deterioration of pumping conditions due to the phenomenon of mechanical inertia.

Any fluid with a higher density is known to contribute to better contamination control by aiding in the transport and removal of solids. Because particles are held in mechanical suspension for longer, they are more easily removed by filters and other particle removal systems, thereby facilitating system cleanup.

As the density increases, the erosion potential of the liquid also increases. In areas of high turbulence or high velocity, the fluid can begin to destroy pipelines, valves, or any other surface in its path.

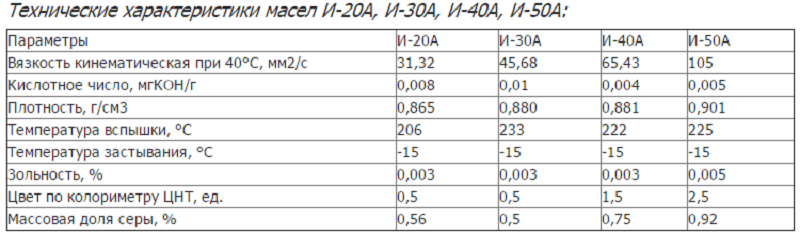

The density of industrial oil is affected not only by solid particles, but also by impurities and natural constituents such as air and water. Oxidation also affects the density of the lubricant: with an increase in its intensity, the density of the oil increases. For example, the density of used industrial oil grade I-40A at room temperature is usually 920±20 kg/m3. But with increasing temperature, the density values change dramatically. Yes, at 40 °With the density of such oil is already 900±20 kg/m3, at 80 °C - 890±20 kg/m3 etc. Similar data can be found for other brands of oils - I-20A, I-30A, etc.

These values should be considered indicative, and only on the condition that a certain volume of oil of the same brand, but which has undergone mechanical filtration, has not been added to fresh industrial oil. If the oil was mixed (for example, I-20A was added to the I-40A grade), then the result will come out completely unpredictable.

How to set oil density?

For the line of industrial oils GOST 20799-88, the density of fresh oil ranges from 880…920 kg/m3. The easiest way to determine this indicator is to use a special device - a hydrometer. When it is immersed in a container with oil, the desired value is immediately determined by the scale. If there is no hydrometer, the process of determining the density will become more complicated, but not by much. For the test, you need a U-shaped calibrated glass tube, a container with a large mirror area, a thermometer, a stopwatch and a heat source. You will need to do the following:

- Fill the container with water by 70 ... 80%.

- Heat water from an external source to the boiling point, and maintain this temperature constant throughout the entire testing period.

- Immerse the U-shaped glass tube in water so that both leads remain above the surface of the water.

- Close one of the holes on the tube tightly.

- Pour oil into the open end of the U-shaped glass tube and start the stopwatch.

- The heat from the heated water will cause the oil to heat up, causing the level at the open end of the tube to rise.

- Record the time it takes for the oil to rise to the calibrated level and then fall back down. To do this, remove the plug from the closed part of the tube: the oil level will begin to decrease.

- Set the speed of oil movement: the lower it is, the higher the density.

The test data is compared with the reference density of pure oil, which will allow you to accurately find out the difference between the actual and standard density, and get the final result by proportion. The test result can be used to evaluate the quality of industrial oil, the presence of water in it, waste particles, etc.

Watch this video on YouTube