Compressor oil density

Content

The concept of density

Compressor oil density is a measure of the ratio of lubricant volume to its weight. One of the most important parameters that affects the workflows within the system.

The higher the density of the oil, the more effectively it protects parts from friction, the better it prevents the formation of carbon deposits and the release of secondary products. A grease that is less dense in consistency works more productively where you need to quickly put the equipment into operation. It instantly penetrates to the elements, effectively lubricating every facet of them.

Also correctly selected compressor oil with a certain density:

- increase the working life of the equipment;

- will be a good helper to start the system in the cold season;

- will take care of the compressor performance during its long-term operation at elevated temperatures.

How and in what units is the density of compressor oil measured?

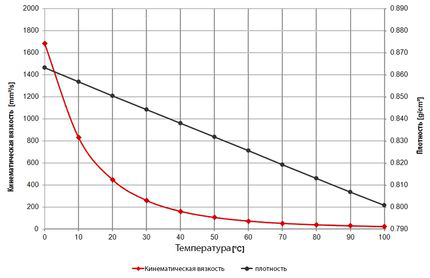

The density of oil is calculated at a certain temperature. The average is +20 degrees Celsius. For the calculation, it is necessary to take the temperature indicator and subtract the average value from it. The resulting difference is then multiplied by the temperature correction. Actual temperature corrections are displayed in GOST 9243-75. It remains to subtract the resulting product from the density parameter, which is displayed in the technical specifications of each specific brand of compressor oil.

Density is measured in kg/m3. Average values, which depend on the brand and viscosity of a particular compressor oil, range from 885 to 905 kg/m3.

Why do you need to know the density index?

As the temperature rises, the initially set density of industrial oil decreases. Accordingly, with a decrease in the temperature regime, this indicator increases again. This information is relevant for service personnel. A change in a predetermined density affects the deterioration of the sealing and lubricating properties of the compressor oil. This, in turn, can cause moisture (condensate) to enter the system and increase friction during equipment operation in the winter, cold season. As a result, the device may be stopped due to breakdowns or premature wear.

Having information about the density of compressor oil and what this parameter depends on, the master or machine operator will be able, taking into account the operating conditions of the equipment, to take measures to prevent malfunctions and change the properties of the lubricant.

Watch this video on YouTube