Pros and cons of car air suspension

Content

The role of elastic elements is performed by pneumatic cylinders made of multilayer dense rubber. They are placed one per wheel. The shape of the cylinders resembles "pills", consisting of several sections. The main function of these elements is to keep the car at the right height above the road.

The air suspension of the car ensures safety and comfort while driving. With proper operation, it lasts a long time and fully compensates for the costs. There are several types of air suspension according to the type of design and control features.

What is "pneumatics"

The operation of the pneumatic system in vehicles is based on the physical properties of compressed air. In the automotive industry, this makes it possible to increase safety and comfort, as well as to supply additional equipment.

This principle is widely used in suspension, brakes and clutch systems.

The main advantages of "pneumatics":

- The technical simplicity of the units and the very principle of the system.

- No special substances are required for operation - atmospheric air “performs” all functions.

- Economic profitability of the installation.

- Security.

Pneumatic suspensions in transport are less common than hydraulic ones. They are mainly put on commercial trucks and premium cars.

Types of air suspension

The air suspension of a car is of three types - single-circuit, double-circuit and four-circuit.

The first type of suspension is installed on the front or rear axle of the car. It is best suited for pickups and trucks. The height of the seat and the elasticity of the suspension can be adjusted. Some systems come with a built-in receiver. Air enters the cylinders until the desired pressure level is reached. If there is no receiver in the air suspension, the air from the compressor goes directly to the pneumatic elements. You can reduce the pressure level with a valve.

Types of air suspension

Dual-circuit systems are installed on 1 or 2 axles. The pluses include:

- high carrying capacity;

- reducing the risk of falling on your side when driving on sharp turns;

- even distribution of machine weight.

In addition to jeeps and trucks, a similar type of suspension is installed when tuning VAZ cars.

The best air suspension mechanism is considered to be four-circuit. It is installed on both axles of the machine and must have a receiver. Electronic pressure level control is used.

Advantages of 4-loop suspension:

- ease of changing ground clearance;

- pressure adjustment depending on the road surface.

The disadvantage of this type is the large mass of the mechanism.

How air suspension works

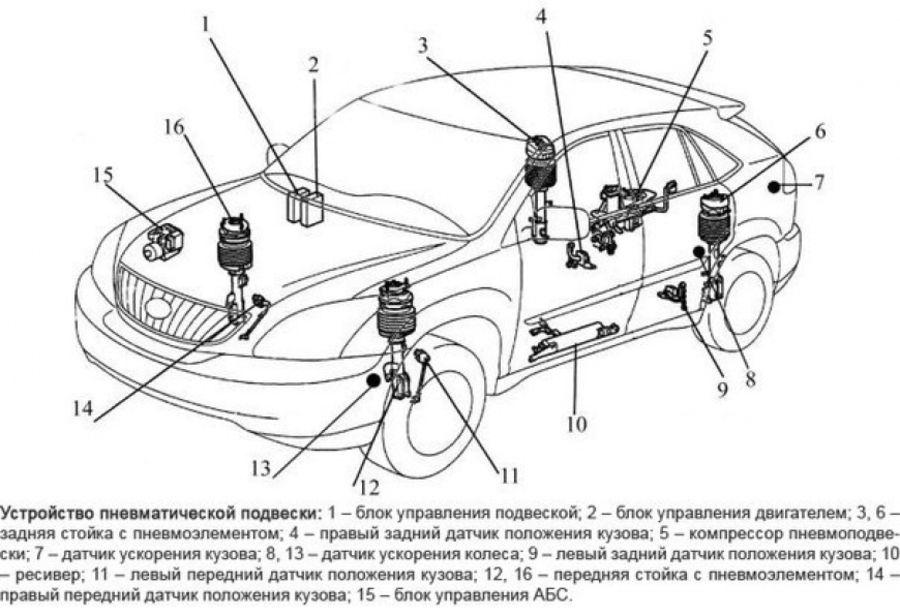

The air suspension device is relatively simple. The mechanism consists of several main parts:

- Pneumopillows (elastic elements).

- Receiver.

- Compressor.

- Control system.

The compressor fills the pneumatic cylinders with compressed air. In turn, this node consists of several parts:

- electric motor;

- electromagnetic valves - they distribute compressed gas along the circuit;

- air dryer.

Depending on the number of valves in the air suspension, the compressor inflates the elastic elements one by one or in pairs. Air does not get there directly, but through the receiver. This part looks like a metal tank with a volume of 3 to 10 liters. Air is pumped here, which then enters the cylinders through solenoid valves. The main function of the receiver is to adjust the pressure in the suspension without using a compressor.

The operation of the air suspension is regulated by a control system that has several sensors:

- car acceleration;

- pressure in the pneumatic system;

- pump temperature;

- position of the vehicle above the road surface.

The data from the sensors is processed by the control unit and transmits signals to the executive bodies of the system. These include compressor relays and pressure control valves.

Manual and automatic air suspension modes

The ride height can be controlled manually or automatically. In the first case, the clearance is regulated by an electronic control system. In the second, the driver sets the clearance manually.

Manual and automatic air suspension modes

Automatic control mode is designed to control:

- ground clearance;

- vehicle speed;

- acceleration of the car while driving;

- the level of inclination when driving uphill or down;

- level of roll on sharp turns;

- suspension stiffness.

The operation of the automatic system is directly affected by the driving speed. If the car goes faster, the ground clearance decreases, while slowing down, it increases.

Manual control allows you to change the stiffness of the suspension and the clearance.

Advantages and disadvantages of air suspension

The air suspension of the car is becoming more and more popular. Now they are installed not only on heavy trucks, but also on premium cars. The advantages of the system include:

- Large clearance adjustment range and improved vehicle patency.

- Support for ground clearance, regardless of the load on the car.

- Minimal roll of the car on sharp turns.

- Good handling on difficult sections of the road.

- Reduced wear on shock absorber springs.

There are also a few downsides. The air suspension must be cleaned regularly to avoid damage to the main components. In addition, rubber cushions can leak air and tear. For some owners, a significant disadvantage is expensive maintenance.