Renault Megane 2 AC Compressor Pulley Bearing

Content

- Renault Megane air conditioner compressor and other causes of malfunctions

- Renault Megan 2 air conditioner compressor: repair price

- When to change the air conditioner bearing for Renault Megan 2

- Renault Megan 2 air conditioning compressor pulley: what is the danger of untimely repairs

- Renault Megan 2 air conditioner compressor: freon leak repair

- Removal and installation of the compressor of the conditioner

The higher the outside temperature, the more car owners appreciate the presence of air conditioning in the car. Without it, driving with the necessary level of comfort in the summer is simply impossible.

However, if the system is not repaired in a timely manner, then only in the summer heat, there is a greater risk of discovering that it is faulty and does not cool the car interior enough.

On Renault Megan, the air conditioner has a rather complicated device and therefore only specialists can often identify the cause of the malfunction. Repair work without sufficient qualifications in the absence of special equipment can easily exacerbate the problem.

Renault Megane air conditioner compressor and other causes of malfunctions

The most vulnerable node in the system

the air conditioner is a compressor. This is partly due to its wide functionality: it takes the refrigerant from the evaporator and pressurizes it into the condenser. Pressure is one of the reasons why the wear of compressor parts is much higher than other elements of this system.

Repair of the compressor is complicated by its rather complicated device, therefore, if it fails completely, the car owner will inevitably face costly repairs.

Renault Megan 2 air conditioner compressor: repair price

If individual compressor components are beyond repair, replacement costs can be very high. The reason is expensive original spare parts and certain difficulties that arise when disassembling the compressor.

However, replacement of this part is required as a last resort. Often timely repair or replacement of the bearing and other components in order to extend the life of the compressor, avoiding costly repairs.

When to change the air conditioner bearing for Renault Megan 2

In most cases, the malfunction of the air conditioning system in this car is associated with the Megan 2 air conditioner bearing. The high wear rate is due to the fact that the bearing is constantly working with the engine. You can determine that the time has come to replace the bearing by the characteristic noise.

Experts distinguish several stages of its manifestation:

- A barely noticeable noise that happens from time to time on a well-heated engine or, conversely, on a cold engine. It usually stops when the air conditioner is turned on.

- The sound gets louder and does not stop under any circumstances.

- The sound becomes so loud that it can be described as a roar or howl. In this case, the source of noise is no longer the bearing of the Megan 2 air conditioner, which probably fell apart safely, but the air conditioner clutch itself. If the repair is not carried out in the very near future, a complete failure of both it and the compressor is likely.

Renault Megan 2 air conditioning compressor pulley: what is the danger of untimely repairs

Untimely replacement

The bearing causes the following damage to the system:

- at the first stage, the compressor seals melt due to severe overheating of the system;

- in addition, due to wear, the insulating varnish in the winding of the electromagnetic clutch burns out;

- with such damage, there is a high risk of complete failure of the clutch, which significantly increases the cost of repairing the air conditioning compressor;

- overheating of the coupling, in turn, prematurely disables the compressor seal, which in the future often becomes a source of freon leakage and system depressurization.

Renault Megan 2 air conditioner compressor: freon leak repair

In the air conditioning system of any car, the lion's share of failures is associated with system depressurization, and Renault Megan is no exception.

Very often the source

leaks turn into a high-pressure pipe, which, at its junction, is exposed to increased dirt and dust. As a result, corrosion here occurs faster than in other nodes, and therefore holes can literally form through which freon escapes.

Another source of leaks is the compressor. However, it is impossible to identify the exact place where the freon comes from, as well as to establish the very fact of its leakage from the system, without special equipment, and therefore, in this case, car repair should be entrusted to professionals.

To begin with, the pressure in the system is determined. If out of specification, a full diagnostic is displayed before the system is primed to determine the source of the leak. In modern car services, it is usually carried out in one of two ways:

- leak detector - an electronic device that indicates the presence of a freon cloud near any node at the leak site

; - phosphor dye, which is added to the system during refueling. As a result, this dye accumulates at the leak site and is easily detected using a special ultraviolet lamp.

If it is determined that the system is depressurized, it must be evacuated. This will remove any air and fluid that may have accumulated there during the release of pressure. If this is not done, a new repair of the Renault Megan 2 air conditioner will be required very quickly.

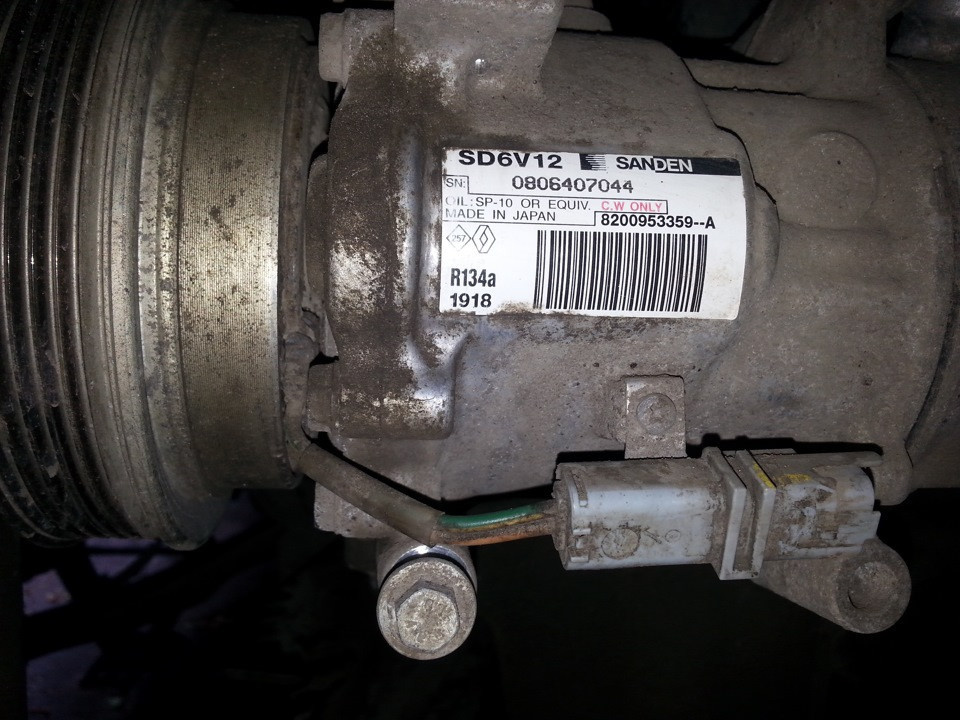

Basically, when the air conditioning compressor is running, the malfunction is the failure of the air conditioning clutch. Bearing 4 (Fig. 1) of the pulley begins to collapse.

The bearing can be destroyed due to excessive tension of the drive belt, water ingress, slippage of the pressure plate 1 (Fig. 1)

Due to the play of the bearing during rotation, the inner surface of the pulley begins to rub against the surface of the housing 10 of the electromagnet coil.

Under the action of friction, the parts heat up, and the insulation of the winding 8 (Fig. 1) of the coil begins to burn out, the turns of the electromagnet coil close, and the electromagnet fails.

There are cases of complete jamming of the bearing and rotation of the inner race 5 of the bearing in the landing shoulder of the compressor cover.

When the compressor is running, you should pay attention to extraneous noise during the operation of the air conditioning compressor. If there is any doubt, remove the drive belt from the pulley and turn the pulley by hand. It should rotate without noise and without jamming. There must be no radial or axial play.

Removal and installation of the compressor of the conditioner

To work, you will need tools: an 18 wrench and a screwdriver with a flat sting.

We prepare the car for work.

We remove the refrigerant from the air conditioning system (article - Features of refueling with Renault Megane 2 refrigerant).

We remove the fender liner from the right front wheel (article - Removing the fender liner from a Renault Megan 2 car).

Remove engine cover

We remove the auxiliary drive belt (article - Replacing the belt of auxiliary units Renault Megane 2)

Check the condition of the drive belt. We replace the belt if the following defects are found:

- toothed surface wear, cracks, nicks, folds or peeling of rubber from the fabric;

- dents, cracks or swelling on the outer surface of the belt;

- weakening or delamination on the end surfaces of the belt;

- traces of oil on the surface of the belt due to leakage of the motor shaft seals.

We press the latches and disconnect the cable block from the electromagnetic clutch block to turn on the compressor.

We unscrew the screws that secure the flanges of the low and high pressure pipes to the compressor.

We unscrew the bolts from the holes and disconnect the pipes from the compressor.

After disconnecting the pipes, the compressor and pipe openings must be plugged.

We unscrew the three bolts that secure the compressor to the cylinder block bracket.

See also: Explanations of the traffic police of the adjacent territory in the traffic police

We take out the screws from the holes and remove the compressor.

Install compressor and all parts in reverse order

We remove the plugs from the compressor holes and the pipe just before connecting. Lubricate the new O-rings with A/C compressor oil.

When installing the belt, it is necessary to ensure that the tracks of the wedge coincide with the pulley currents.

We fill the air conditioning system. If a new compressor is being installed, it is necessary to know how much oil is filled in the compressor and the type of oil.

Tools:

- Pliers

- Rubber hammer

- Press tool for bearings

- Three-finger puller 100 mm

- Head 14mm

- Head 30mm

- Key to grinder

- Roulette

Spare parts and consumables:

- Подшипник 35BD219T12DDUCG21 размер 35x55x20

Note:

It all started with the fact that when the air conditioner was running, a terrible sound was heard. It turned out that the whole reason was in the air conditioner pulley bearing, I decided to replace it.

1. I unscrewed the nut, and without much effort, although before that I had sprayed it with “WD-40 type” grease and warmed it up with a lighter, so it could have been easily unscrewed.

The pressure plate was then removed with a screwdriver, and yet it was easily removed by hand, as was the pulley.

Note:

The head for 14 should not be more than 22mm in diameter, otherwise it will not work, and since the nut is slightly recessed, do not unscrew it with a key, only with the head.

And when removing the pressure plate, make sure that the spacer is not lost, it is necessary for a certain gap between the pulley and the plate, it must be removed before removing the pulley.

2. I looked at the bearing on the pulley, the size and rigidity are the same.

After that, things went faster, straightened the notches with a screwdriver and knocked out the old bearing with the help of a nearby free cobblestone, the mallet also came in handy, then carefully hammered the new bearing with it.

Assembly in reverse order. For convenience, I removed the right wheel with the front part of the wing and the bumper with a protective plastic screen.

3. Unscrew the nut with a grinding key.

4. We take out the protective ring.

5. Unscrew the head nut.

6. We take out the bearing.

Comparison of new and old.

Need head size.

Three-finger puller 100 mm.

7. We press in a new bearing and assemble everything in the reverse order.