Underwater minelayers of the Kriegsmarine

U 116, the first of the XB type submarines on sea trials in 1941.

In the interwar period, the Germans used the experience of the First World War, which showed the uselessness of small surface minelayers and the need to develop large submarines equipped with devices for transporting, arming and laying sea mines, capable of stealthily approaching their location.

During World War I, the Kaiserliche Marine laid over 43 mines. They caused such great damage to the British coast that the trade routes had to be mined daily. To this end, at the end of 000, all suitable trawlers were adapted to work as minesweepers, each averaging 1916 nautical miles per day. Type A EM (Einheits Minen) contact-anchor mines (250 kg of explosive charge) and larger versions of EMB (150 kg) and EMC (220 kg) were widely used by the Germans. Initially, submarines were used only to mine places that were inaccessible to miners: paths near lighthouses, approaches to ports and anchorages.

Submarine mines were most often stored and transported inside a strong hull (“dry”), and this method was generally considered necessary. To accommodate as many mines as possible, the dimensions of the installation had to be very large and it had to be equipped with sufficiently large expansion tanks. Mines were placed in horizontal pipes with a diameter of about 1 m, covered with lids on both sides. Over time, the first underwater minelayers of the EU II type: U 117 ÷ U 126 were additionally equipped with 6 oblique (almost vertical) mine shafts in the bow, adapting EMS wet storage mines to them.

U 119 at the Kiel dock in the summer of 1942. Due to the frequent breakdowns of underwater minelayers, shipbuilders nicknamed them boomerangs.

The largest of the submarines

After the start of the expansion of the U-Bootwaffe (since 1935), the operational department of the Naval Command (OKM - Oberkommando der Marine) was interested in building a large underwater mine installation capable of building multi-row paddocks in hard-to-reach areas. . Design work began in early 1937 with the intention of developing by the end of World War I Project 45 (1500-ton minelayers UE II) - equipped in the stern with a horizontal mine-laying tube - using many elements of the first torpedo launchers, the ocean type IX has already been ordered .

The new, significantly enlarged block, marked with the number X, contains, among other things, vertical mine shafts in the bow and sides of the pressure hull, larger main engines, two 7-meter stern torpedo tubes instead of 6-meter ones1 and many other changes that increase the parameters unit to the following values: maximum displacement 2284 m3, length 103,2 m, width 8,85 m, height 4,41 m. In the same year, a new non-contact mine with a magnetic fuse - CM (Schacht Mine) type A, 2,1 m long, 1,35 m high in diameter and with an explosive mass of 500 kg. Also had to increase the diameter of the shafts, which increased the width of the vessel to 9,52 cm and displacement to 2400 m3. At that time, the problem of changing the zone in the magnetic fuse had not yet been solved, so it was decided to store some of the mines dry in the aft compartment - they were supposed to be introduced through a horizontal pipe - a gateway.

Design marked X A failed and had to be adjusted. Prospective work with a new mine shaft designed to be placed in mine shafts, SM and a magnetic fuse made it possible to abandon dry storage of mines (as well as from a horizontal lock for their placement), due to which the size of the installation was reduced (from 2284 m3 to 1710 m3), which made it possible to achieve an increase in the maximum surface speed from 14 to 18 degrees. In the end, the design, which was significantly different from the UC type of the first war, which now received the designation XB, provided for a vertical freely floodable shaft shafts placed in a strong hull (tests were used with such shafts carried out during the First World War) and beyond - on both sides of it. The mines in these mines were stored “wet”, which reduced the size of the hard hull and expansion tanks of the installation (eight expansion tanks on the right and left sides: four inside and four outside the pressure hull, with a total capacity of 42 m3).

The windows were open at the bottom and closed at the top with openwork hinged covers. At the height of the mine anchors, there were hydraulic mechanisms for holding and releasing mines (after releasing the latches, the mines fell out under their own weight). In 1938, German designers developed the self-adjusting FaB magnetic fuze for mines transported in this way, solving the problem of not having access to wet mines stored in mines.

Plan Z for the expansion of the Kriegsmarine from 1938 (later modified) called for the construction of, among others: two 2000 ton Type XI gun mounts, two 2000 ton Type X underwater minelayers, nine Type IX units, and 38 Type VII B units.

Since then, the design work has been gaining momentum, and soon the XB could be put into series production. However, in the plans of the OKM, in contrast to the operational department, the miners played a secondary role, and the limited raw materials intended for underwater weapons were directed mainly to the construction of submarines actively fighting with the merchant fleet: types II, VII and IX (according to the commander diving by Karl Dönitz, the armament of submarines in the Z plan, reinforced after the May crisis in 1938 due to fear of British intervention, in terms of the construction of submarines, did not have the proper status.Thus, the largest unit of the XB type is not had a very high priority.In addition, its main weapon - the SMA anchor mine - was not ready for mass production in time.

On January 31, 1939, the Germania-Werft shipyard in Kiel received an order for three units: U 116, U 117 and U 118, in August for the fourth - U 119, in August and December 1940 and four more: U 219 , U 220, U 233 and U 234. Due to the low priority, the construction of miners was extended and they were put into service in the following years: 1941 - three units (in July, October and December), 1942 - two parts (in April and December), 1943 - two parts (in March and September), 1944 - one part (in March). The first of eight units was launched on May 3, 1941.

Six mines, containing three mines stacked one above the other, were located in the bow of the ship and passed through the center of the strong hull (initially, there were seven mines for two mines). On both sides, in addition to a strong hull, there were twelve mines, each with two mines; a total of 66 min SMA were stored. To compensate for stability, the front living compartment and the battery compartment located below it are separated, and a control panel with a kiosk has been moved to their center. The defensive armament of the submarine consisted of two stern torpedo tubes and artillery: 10,5 cm L / 45 guns, 3,7 cm guns and two 2 cm guns.

Type VIID

In September 1939, the TMA anchor mine with a magnetic fuse was not yet ready for use, the U-Bootwaffe had only TMB bottom mines (from a torpedo tube), in water areas up to 30 m deep (subsequently limited to 25 m). The first two XB units were built to build large SMA bottom mines, but these large ships had to operate in distant areas. In the absence of medium caliber underwater mines for SMA mines, a decision was quickly made to redesign the VII C submarine, which has proven effective in laying TMB mines in shallow coastal waters.

The design change mainly consisted of adding a compartment behind the control panel, about 9,8 m long, with five vertical mine shafts (previously built for the XB type), in which there were three mines located one above the other. After the change, the non-commissioned officer's living compartment, which was previously located immediately behind the headquarters, was located behind the shaft compartment. Expansion and control tanks were also added. An additional advantage was the lengthening of the fifth wheel fuel tanks, which increased the fuel capacity by 56 tons, which increased the flight range by 1600 mm (from 6500 to 8100 mm). The enlargement of the unit also led to a slight decrease in the developed maximum speed (from 17 to 16 knots). The submarine's five-tube torpedo armament remained unchanged, so instead of torpedoes, she could carry torpedoes in addition to 15 SMA mines.

On February 16, 1940, the Germaniawerft shipyard in Kiel received an order for 6 units of VII D (U 213 ÷ U 218). The construction of the first block began on October 1 of the same year. The units entered service sequentially from August 1941 to January 1942.

Mines

After World War I, under the Treaty of Versailles, Germany lost its entire fleet, which at the time of the start of the next world armed conflict was only undergoing intensive expansion, so mine pens were supposed to limit the operational capabilities of the enemy fleet, interfere with navigation, compensating for the insufficient capacity of its own fleet.

Torpedomine

After the start of the development of the U-Bootwaffe, the designers were given the task of building a mine designed specifically for the U-Boat, which could be installed without special equipment for units with mine shafts - through torpedo tubes. Initially, a TMA mine (Torpedomina A) with a mass of 230 kg and a cylindrical shape with a diameter of 53 cm was used for testing. It was successfully launched from a submarine torpedo tube and anchored.

Tests of the first submarine built since 1935 (type II A, B, C and D) showed that after the elimination of minor technical problems, these units are quite suitable for the role of miners and can take mines into their torpedo tubes. instead of torpedoes. The following types of mines with a load increased to 560 and 930 kg received the TMB and TMS markings, respectively. These mines became the main types of naval mines thrown by submarines with compressed air from torpedo tubes.

TMA

Anchor mine with a contact fuse introduced after 1935 (since 1940 with a magnetic fuse), with an aluminum alloy body, 3380 mm long (two in each of the launchers), weight 800 kg, including an explosive charge of 215 kg of hexanite , with adjustable embedment depth 15 ÷ 30 m after 1 m. Activation time after ejection 10 min.

TMB I and II

A bottom mine with a magnetic detonator (sensitivity as a SMA mine), introduced in 1939, acoustic and acoustic magnetic since 1942, cylindrical in shape with a bolted (TMB I) or welded (TMB II) aluminum alloy body, 2300 mm long and weighing 740 kg, including the following loads: TMB I - 580 kg, TMB II - 560 kg. This mine, in the TMB/S variant, has also been used by Schnellboots since the 1940s. It is possible to install a clock mechanism with a self-liquidator, with the possibility of installation up to 80 days. At the beginning of the war, TMB mines were placed at a depth of 30 m, but due to insufficient effectiveness, Dönitz limited the depth to 22-25 m. Excessive fuse sensitivity caused explosions in small aggregates, as a result of which this value was reduced.

TMS I and II

The bottom mine, introduced in 1940 at the request of Dönitz (it was an enlargement of the TMB), was intended to combat linear units equipped with acoustic (since 1940) and acoustic-magnetic (since 1942) detonators, 3390 mm long (two mines), weight 1100 kg, load 860-930 kg, installation to a depth of 37 m, it was possible to set a deactivating clock (as on a TMB mine).

During World War I, the Germans developed a series of a dozen or so varieties of EM contact anchor mines (Einheits Minen) with various warhead sizes. All of them could be placed on ships or submarines. The most common was an EMS mine (type C), spherical, 1,12 m in diameter, made of steel sheet 3,5 mm thick, with a load capacity of 300 kg and positive buoyancy, was dropped into the water along with a mineline wound on a drum. heavy foundation (anchor) settling to the bottom. Immediately after the release of the mine into the water, as a result of a chemical reaction, the blockade of the mineline was removed, as a result of which the mine separated from the anchor and unwound the mineline to a predetermined depth. Such a quick release of the mineline blockade caused the positively floating mine to float to the surface immediately after being dropped into the water, until the anchor dragged it under the surface of the water. This phenomenon was not a problem for surface minesweepers, but there was a risk of irradiation of underwater mines (mining was carried out with a shallow draft of several meters).

After the Great War, the Germans had large stockpiles of mines, including those of the EMS type used during World War II. In the 30s, a device was designed that released a mineline with a delay, at a depth of 130 m. As a result, the mine immediately gained depth along with the anchor after it was released. At a depth of less than 130 m, the mechanism released the brake after 0-7 minutes (the shallower the depth, the later). This invention made it possible to start work on a new type of underwater mine layer equipped with mine shafts.

The underwater mine installation U 117 of the times of the first war, equipped with freely floodable mine shafts, could dive to a depth of 75 m. A pressure of about 7,5 atm at this depth did not pose a threat to the mines. The minelayer of the new type XB was supposed to descend to a depth of 200 m, where the pressure was within 20 atm, destroying mines. Thus, in order to be able to take full advantage of the characteristics of the new type of unit, it was necessary to develop a new type of mine. When the first submarine of this type, U 116, was completed and handed over to the Kriegsmarine in July 1941, there were no operational mines for it yet. After many delays, they were not introduced until the autumn of 1942.

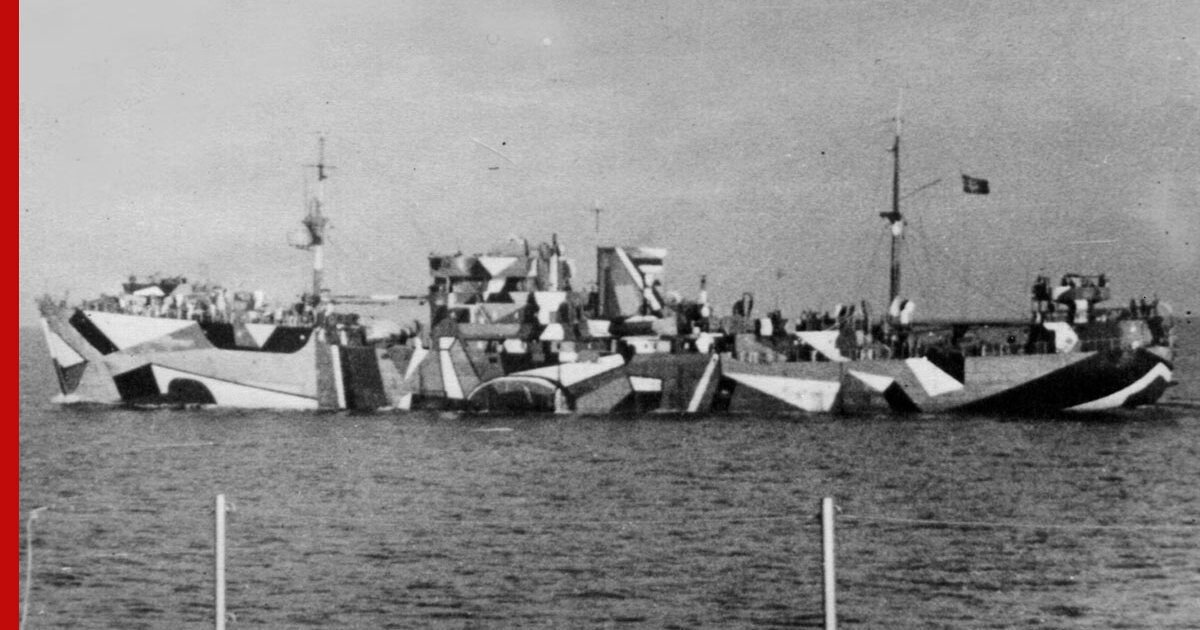

U 118 type XB in the spring of 1942 in Kiel.

Shachtmine

The construction of minefields using TMB and TMK bottom mines was possible only at depths up to 30 m (subsequently limited to about 25 m), and work on the TMA anchor mine was delayed, and its 230-kilogram load was too small. . For this reason, already in 1937, work began on the SM type A (Schachtmine), intended for the construction of vertical shafts of an underwater mine of type X B.), with a diameter of 8 mm (9-1331 mm) and a mass of 1327 kg, including hexanite load 1334,5-1575 kg. We used a new magnetic detonator FaB with a sensitivity of 340 mOe (millersted is a unit of magnetic field strength in the cgs system). The mine was located at depths up to 350 or 20 m (depending on the length and section of the mineline).

Depth setting was regulated in the range of 15-30 m from the water surface with an accuracy of 1 m. Setting in the range of 15-6 m was allowed only in areas with calm seas and slight waves. It was not allowed to place these mines at a sea depth of less than 50 m. Activation time from recoil: 30-40 minutes, adjustable up to 6 days. At the beginning of the war, the mine was not ready for production and entered service only in the second half of 1942, but due to the high sensitivity of the magnetic fuse, its use was suspended until the spring of 1943, when the sensitivity was halved.