Polyester primer for cars: rating of the best. How to use polyester primer

Content

For minor damage, aerosol cans are indispensable. Polyester primer for cars is applied in a few minutes. After complete drying, the surface is sanded, so that the defect disappears.

Vehicle owners know that the result is not so much affected by the quality of the paintwork, but by correctly performed preparatory work. Today, for such purposes, polyester primer for cars is more often used. This type of coating began to be used not so long ago, in comparison with polyurethane and acrylic options.

What is polyester primer for cars

The material began to be studied in the 1930s, and since 1960 the resulting compositions have been used in all industries. Based on saturated polyester resins. The primer is used in the automotive industry in order to obtain a transparent glossy finish.

The substance outperforms other materials with good adhesion, surface hardness, chemical resistance, abrasion and scratch resistance.

Polyester primer

Polyester primer for cars consists of three components:

- the basis;

- accelerator;

- catalyst.

Before use, the elements are mixed, observing the proportions indicated by the manufacturer. The substance has a specific smell due to the presence of styrene - this is a reagent that is part of saturated polyesters.

The mixtures contain paraffin, which does not allow free radicals of the monomer to enter into a chemical reaction with oxygen during decomposition, and the connection between the surface of the body and the primer is faster. After drying, the layer is removed by grinding.

Material advantages

The main advantage of a polyester primer for cars in spray cans is that it dries quickly on the surface of the body. If the room temperature is 20ºWith or above, the process takes 90 to 120 minutes. When using an industrial hair dryer, the drying speed increases several times. The only condition is that the permissible temperature must not be exceeded.

In addition to the spray can, a gun or spray gun is used to apply the primer. The composition has high physico-chemical properties. One layer is enough to obtain the required dry residue, which saves material.

Putty with carbon fiber

Unlike acrylic primers, polyester primers do not boil when smudges form and the resulting surface is easy to grind. Withstand temperatures from -40º to +60ºС.

Thanks to these properties, the material occupies a leading position in the market.

Polyester primer for cars: rating of the best

The main goal is good adhesion with subsequent layers. Therefore, the primer is subject to increased requirements, in comparison with other mixtures used in the restoration of the surface of the car.

Among the products on the market are the following.

| Name | Manufacturer country |

| NOVOL 380 | Poland |

| Body P261 | Greece |

| "Temarail-M" Tikkurila | Finland |

| USF 848 (100:2:2) | Russia |

| "PL-072" | Russia |

Each product has its advantages, and the choice is made depending on the conditions of the upcoming work.

NOVOL 380 polyester primer Protect (0,8l + 0,08l), set

It is important to study the characteristics of each of the materials presented in the assortment in order to purchase the most suitable one.

Protect polyester primer

| Country of Origin | Poland |

| Weight, kg | 1.6 |

| appointment | polyester |

| Warranty | 2 years |

| Color | Beige |

Filling coating of a new generation. The main advantage is low consumption during use, 50% more profitable than acrylic primers. NOVOL 380 perfectly fills uneven substrates and pores in putty. After drying, the shrinkage of the material is low.

Before starting work, it is enough to mix the primer with the hardener, no need to use thinners and solvents. If the color of NOVOL 380 changes from olive green to beige, then the primer is ready for use. During operation, a gun is used to apply the mixture: the required nozzle diameter is 1.7-1.8 ml.

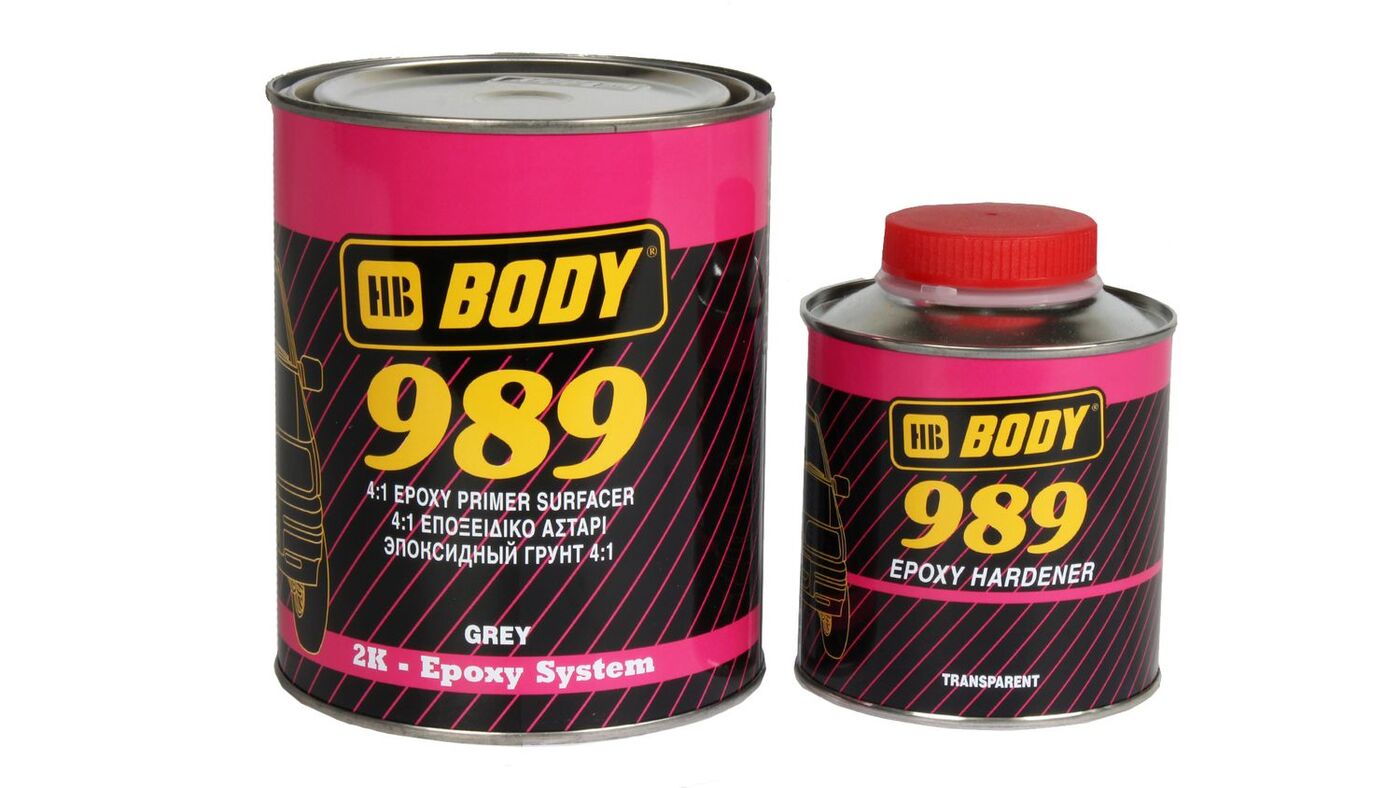

Body P261 Polyester primer 1L + 50 ml

Coating designed for application on areas with small irregularities. It has a high dry residue content, good adhesion characteristics with all surfaces: metal, fiberglass, wood.

| A type | Two-component |

| Manufacturer country | Greece |

| Volume | 1050 ml |

| Color | Light gray |

Can be applied in thick layers. At temperatures above 23ºС dries in 3 hours. Body P261 is painted with any kind of enamel. Together with the primer, the kit includes BODY HARDENER hardener, 0.2 liter volume.

Mix in a ratio of 100 parts of Body P261 to 5 - BODY HARDENER. The material is used within 30 minutes after mixing.

Polyester automotive primer requires three coats when applied at low pressure of 1,5-2 Bar.

"Temarail-M" Tikkurila (Temarail)

The material is fast drying and contains anticorrosive pigments. After priming, the area can be subjected to welding and flame cutting. The resulting damage is minimal and easy to clean with a regular steel brush.

Polyester primer "Temarail-M" Tikkurila

| A type | Single component |

| Manufacturer country | Finland |

| Density | 1,3 kg / l |

| Color | TCH and TVH database. |

They are used to protect against damage as a result of interaction with the environment of such surfaces as:

- steel;

- aluminum;

- galvanized steel.

Temarail-M Tikkurila has excellent anti-corrosion and adhesive properties.

During processing, it is important to observe the following conditions:

- The vehicle surface must be dry.

- The temperature in the room is not lower than +5ºС.

- Air humidity is not higher than 80%.

Before applying the composition, the aluminum body is prepared using sandblasting or polished.

Polyester primer USF 848 (100:2:2)

The mixture consists of base, accelerator and hardener. The composition is used to enhance the adhesive properties. For example, if it is necessary to create hybrid materials consisting of wood and resin. When coated with USF 848, the surfaces adhere strongly.

| A type | three-component |

| Manufacturer | COMPOSITE-PROJECT LLC |

| Manufacturer country | Russia |

| The weight | 1.4 and 5.2 kg/l |

| appointment | adhesive |

The composition is kneaded in proportion: resin part 1 kg, accelerator 0,02 kg, hardener 0.02 kg.

Polyester primer "PL-072"

Used to protect the car body from corrosion. The material does not require additional grinding and other treatments. It has good hardness, increases the resistance of the coating to chipping.

Polyester primer "PL-072"

| Manufacturer | LLC "EUROPE SIGN" |

| Manufacturer country | Russia |

| Density | 1,4 and 5.2 kg/l |

| Color | Grey. Hue is not standardized |

| appointment | adhesive |

After drying, the primer "PL-072" forms a smooth surface, without pockmarks and craters.

How to properly use a polyester primer for cars in spray cans

After a competent choice of composition, compliance with all norms in work is the key to a successful result.

The process consists of several stages:

- Before starting, the surface of the machine is cleaned.

- To improve the adhesive characteristics, the area is degreased.

- The selection of the composition depends on the coverage.

- Polyester primer for cars in spray cans is applied at an angle of 90º from a distance of 25–30 cm from the surface.

- 2-3 layers are enough to complete the work.

For minor damage, aerosol cans are indispensable. Polyester primer for cars is applied in a few minutes. After complete drying, the surface is sanded, so that the defect disappears.