Steering rack failure. Signs of breakdown and repair

Content

- turn the steering wheel with considerable effort;

- when the steering wheel is turned, a hum is heard;

- in motion, a knock or rattle is heard in the area of \uXNUMXb\uXNUMXbthe front axle, when driving through bumps, vibration is felt on the steering wheel;

- leakage of the working fluid, its traces can be seen on the asphalt after parking;

- the steering wheel has play;

- steering wheel jamming;

- defective boot on the tie rod.

- do not leave the steering wheel in the extreme position for more than 5 seconds;

- slow down if you have to drive on a bad road or overcome speed bumps, rails and other obstacles;

- monitor the level of the working fluid in the power steering reservoir;

- in winter, before starting to move, gently turn the steering wheel in both directions a couple of times, this will allow the fluid in the power steering to warm up;

- regularly check the condition of the anthers.

Driving comfort and safety on the road depend on the perfect operation of the steering of the vehicle. Therefore, for any motorist it will not be superfluous to understand the basic principles of the functioning of the steering system and know what to do if certain defects occur in it.

The central place in this system is occupied by the steering rack.

The rack and pinion mechanism has long been used to turn the wheels of a car. And although it is constantly being refined and improved, the basics of its work as a whole remain the same.

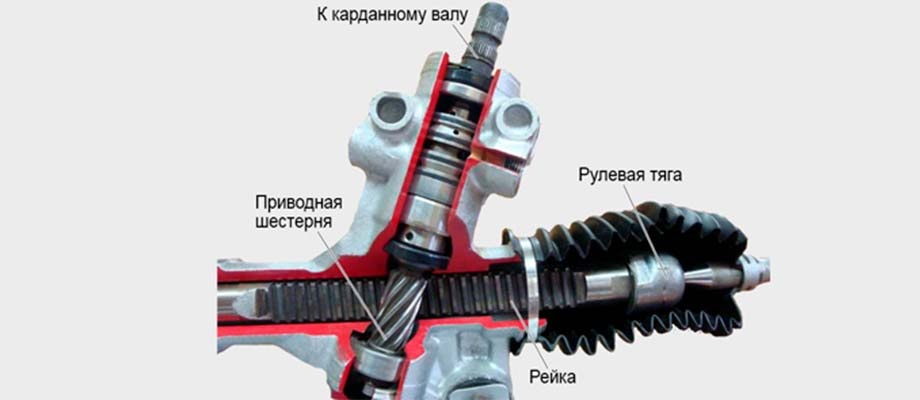

To convert the rotation of the steering wheel into the rotation of the wheels, the principle of a worm gear is used. When the driver turns the steering wheel, he thereby rotates the drive gear (worm) that meshes with the rack.

Depending on the direction of rotation of the steering wheel, the gear rack moves to the left or right and, using the steering rods connected to it, turns the front wheels.

Depending on the direction of rotation of the steering wheel, the gear rack moves to the left or right and, using the steering rods connected to it, turns the front wheels.

The toothed rack is placed in a cylindrical housing (crankcase), which is usually made of an aluminum-based light alloy and is attached to the vehicle chassis parallel to the front axle. Rods are screwed to the rail on both sides. They are metal rods with a ball joint and threaded rail side. At the other end of the rod there is an external thread for screwing on the tip. The steering tip has an internal thread on one side, and a ball joint on the opposite end for connection to the steering knuckle.

Rods are screwed to the rail on both sides. They are metal rods with a ball joint and threaded rail side. At the other end of the rod there is an external thread for screwing on the tip. The steering tip has an internal thread on one side, and a ball joint on the opposite end for connection to the steering knuckle. The tie rod swivel with the rack is protected from dirt and moisture with a rubber boot.

The tie rod swivel with the rack is protected from dirt and moisture with a rubber boot.

Also in the design of the steering mechanism there may be another element - a damper. In particular, it is installed on many SUVs to dampen vibrations on the steering wheel. The damper is mounted between the steering rack housing and the linkage.

The drive gear is mounted on the lower end of the steering shaft, on the opposite side of which is the steering wheel. The required tightness of the gear to the rack is provided by springs.

A mechanical steering rack for control requires significant physical effort, so it has not been used in its pure form for a long time. In some cases, the problem is solved by the use of the so-called planetary mechanism, which allows you to change the gear ratio of the drive gear.

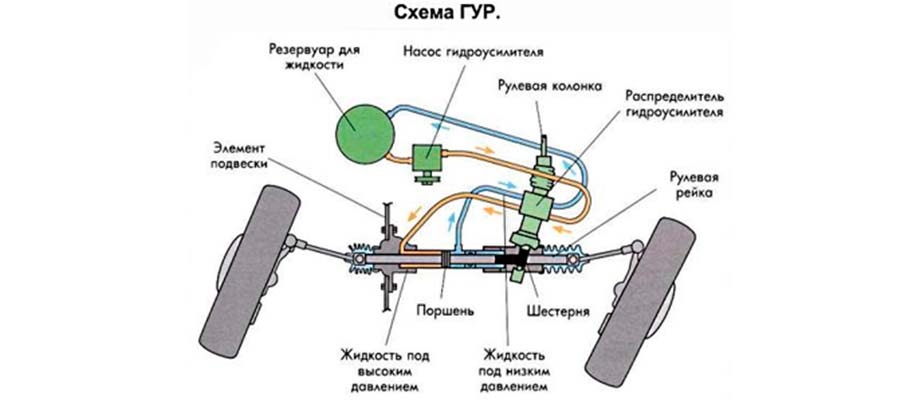

Power steering helps to significantly reduce the degree of fatigue while driving. This is a closed-type hydraulic system, which includes an expansion tank, a pump with an electric motor, a block of hydraulic cylinders, a distributor and hoses. A hydraulic cylinder capable of creating pressure in both directions can be made as a separate element, but more often it is mounted in the steering rack housing. The required pressure drop in the cylinders is created by a control spool located in the steering column and reacting to the rotation of the shaft. The piston of the hydraulic cylinder pushes the rail in a given direction. Thus, the physical effort required to turn the steering wheel is reduced.

The required pressure drop in the cylinders is created by a control spool located in the steering column and reacting to the rotation of the shaft. The piston of the hydraulic cylinder pushes the rail in a given direction. Thus, the physical effort required to turn the steering wheel is reduced.

The hydraulic steering rack is installed on the vast majority of cars produced today.

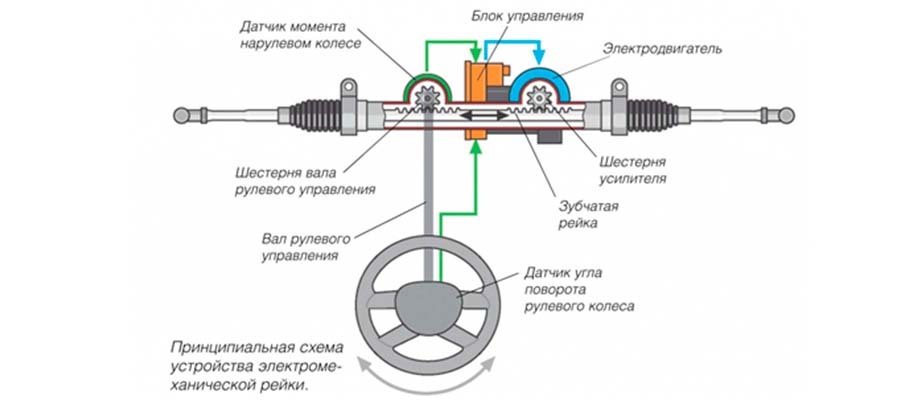

Another assistant that makes it easier for the driver to control the vehicle is the electric power steering (EPS). It consists of an electric internal combustion engine, an electronic control unit (ECU), as well as steering angle and torque sensors. The role of the rail closer is played here by the electric internal combustion engine, the operation of which is regulated by the ECU. The required force is calculated by the control unit based on the data received from the sensors.

The role of the rail closer is played here by the electric internal combustion engine, the operation of which is regulated by the ECU. The required force is calculated by the control unit based on the data received from the sensors.

The steering system with the EUR has been used relatively recently, but it is already clear that it has good prospects. It has a simpler and more compact design. Due to the absence of liquid and pump, it is easier to maintain. It allows you to save fuel, since the internal combustion engine turns on only during the rotation of the steering wheel, in contrast to the one that works all the time. At the same time, the EUR significantly loads the on-board electrical network and is therefore limited in power. This makes it impossible to use it on heavy SUVs and trucks.

The steering system usually functions reliably and lasts for a long time. However, like every other part of the car, the steering rack and related parts are subject to natural wear and tear. Sooner or later, breakdowns occur in the steering. This process is accelerated by a sharp driving style, operation on bad roads, as well as unsuitable storage conditions, for example, in a damp room or in the open air, where the likelihood of corrosion is high. The service life can also be reduced by initially poor build quality or the use of defective parts.

Certain symptoms can give early warning of a possible breakdown. What should be of concern:

If there is at least one of the listed symptoms, you should immediately start repairing the steering system. Do not wait until an expensive steering rack finally fails. If you respond in time, then, perhaps, everything will cost by replacing a few cheap parts from the repair kit, which usually includes bearings, bushings, oil seals, o-rings. Such repairs are available for self-carrying out, but a viewing hole or a lift is required.

Steering wheel hard to turn

In normal condition, with the engine running, the steering wheel is easily rotated with one finger. If you have to apply a noticeable effort to rotate it, then there is a problem with the power steering or the power steering pump has failed. Fluid may leak and air may enter the hydraulic system. It is also necessary to diagnose the integrity and tension of the pump drive belt.

In addition, a “heavy” steering wheel may be the result of incorrect operation of the spool or annular wear inside the distributor.

Annular wear occurs as a result of friction of the Teflon rings of the spool coil against the inner wall of the distributor housing. At the same time, furrows gradually appear on the wall. Due to the loose fit of the rings to the walls, the oil pressure in the system drops, which leads to the weight of the steering wheel. It is possible to eliminate the breakage by boring the inner wall and pressing in a bronze sleeve suitable for the dimensions of the spool mechanism.

It is impossible to prevent ring wear, but if you monitor the cleanliness of the fluid, periodically change it and flush the hydraulic system, you can significantly extend the life of this unit. The fact is that the development is greatly facilitated by the presence of metal chips, which appear in the oil as a result of friction of the interacting parts.

Accurate diagnostics and repair of the power steering requires disassembly of the steering rack, so if there is a suspicion of a power steering breakdown, you should contact a car service. And it is better to look for experienced craftsmen.

Knocking

While driving, even on a not very broken road or on some types of road surface (rubble, cobblestone), and even when crossing the rails, a knock is clearly heard in the front of the car on the left, right or in the center. In this case, steering wheel play and vibration on the steering wheel can often be observed.

Such a symptom should never be ignored. And it's not all about discomfort. If it knocks, it means that something is loose somewhere, worn out. Ignoring it will only make matters worse and may eventually lead to total steering failure. Therefore, one should not hesitate to identify and eliminate such a breakdown.

Knocking can be caused by broken rack bushings, tie rod bushings, or steering shaft bushings. A loose hinge of the tip or rod can knock. The bearing at the bottom of the distributor, on which the steering shaft rotates, can also be broken. If you remove the rail completely, then it will most likely not be difficult to identify the faulty element. Worn items must be replaced.

Another possible cause of knocking is a gap between the worm and the rack, which appears as a result of wear. You can try to tighten it, but if there is serious wear, the adjustment will not give the desired result, and then you will have to replace it.

Knocking and sticking of the steering wheel are also possible due to deformation of the steering rack as a result of the impact. In this case, it must be replaced.

It should be remembered that some details can make a similar knock, in particular,. Therefore, if everything is in order with the steering system, and there is a knock, diagnose.

Hum and rattle

The hum comes from the power steering pump, which is on its last legs and needs to be replaced. Or the pump drive belt is loose. In addition, you need to diagnose if there is a fluid leak. This symptom is often accompanied by "heavy" steering.

In a system with an electric steering rack, a worn-out internal combustion engine of the EUR can hum.

If, while turning the steering wheel, you hear a rattle, then this is a sign of corrosion of the steering shaft or bearing in the distributor. The bearing in this case needs to be replaced, the steering shaft can be sanded if there is little rust. If corrosion has severely damaged the distributor, it will have to be replaced.

Fluid drains quickly

If you constantly have to add fluid to the reservoir of the hydraulic system, it means that there is a leak somewhere. It is necessary to diagnose the integrity of the hoses, identify and replace worn seals and seals in the rail, pump and distributor. Wear of oil seals and O-rings occurs naturally due to the friction of moving parts and the effects of pressure and heat. The process of their wear is noticeably accelerated by rust on the parts of the rail, which can appear as a result of moisture entering through a torn anther.

Steering wheel sticking

Such a malfunction can be caused by various reasons. To identify it, a comprehensive troubleshooting of the steering in a car service is required. It is possible that the situation has reached a critical level, so repairs should be made as soon as possible.

anther defect

To determine the condition of the anthers, you will have to look under the bottom of the car. Anther is not a trifle at all. Even a small crack can lead to loss of lubrication and the ingress of dirt and water into the swivel. As a result, after some time, it will be necessary to replace the thrust or even the entire steering rack, since moisture can penetrate the rack housing and cause corrosion of internal parts. It is easier and much cheaper to replace a torn anther in time.

Ignoring the symptoms of a breakdown will sooner or later lead to the final breakdown of the steering rack and significant cash costs. The worst-case scenario is steering wheel jamming. If this happens at high speed, then it is fraught with an accident with serious consequences.

To extend the life of the steering rack will help the observance of some simple rules: