Generator breakdowns - signs, diagnostics, causes, testing

Content

Breakdowns in the electrical equipment of a car are very common and occupy one of the leading places in the list of breakdowns. They can be conditionally divided into breakdowns of current sources (batteries, generators) and breakdowns of consumers (optics, ignition, climate, etc.). Main the car's power supplies are batteries and generators. the breakdown of each of them leads to a general breakdown of the car and its operation in abnormal modes, or even to the immobilization of the car.

In the electrical equipment of a car, the battery and the alternator work in unbreakable tandem. If one fails, after a while the other will fail. For example, a broken battery leads to an increase in the charging current of the generator. And this entails a breakdown of the rectifier (diode bridge). In turn, in the event of a breakdown of the voltage regulator coming from the generator, the charging current may increase, which will inevitably lead to a systematic recharge of the battery, “boiling away” of the electrolyte, rapid destruction of the plates and failure of the battery.

Common generator failures:

- wear or damage to the pulley;

- wear of current-collecting brushes;

- collector wear (slip rings);

- damage to the voltage regulator;

- closure of the turns of the stator winding;

- wear or destruction of the bearing;

- damage to the rectifier (diode bridge);

- damage to the charging circuit wires.

Common battery failures:

- short circuit of the electrodes / plates of the battery;

- mechanical or chemical damage to the battery plates;

- violation of the tightness of battery cans - cracks in the battery case as a result of impacts or incorrect installation;

- chemical oxidation of the output terminals of the battery. The main reasons for these malfunctions are:

- gross violations of operating rules;

- expiration of the product's service life;

- various manufacturing defects.

It is very useful for a motorist to know the main causes of generator malfunctions, ways to eliminate them, as well as preventive measures to prevent breakdowns.

All generators are divided into generators alternating и direct current. Modern passenger vehicles are equipped with alternators with a built-in diode bridge (rectifier). The latter is necessary to convert current into direct current, on which the car's electrical consumers operate. The rectifier is usually located in the cover or housing of the generator and is one with the latter.

All electrical appliances of the car are designed for a strictly defined range of operating currents by voltage. usually, operating voltages are in the range of 13,8–14,8 V. Due to the fact that the generator is “tied” with a belt to the crankshaft of the internal combustion engine, from different revolutions and vehicle speeds, it will work differently. It is for smoothing and regulating the output current that the relay-voltage regulator is intended, which plays the role of a stabilizer and prevents both surges and dips in the operating voltage. Modern generators are equipped with built-in integrated voltage regulators, colloquially referred to as "chocolate" or "pill".

It is already clear that any generator is a rather complex unit, extremely important for any car.

Types of generator faults

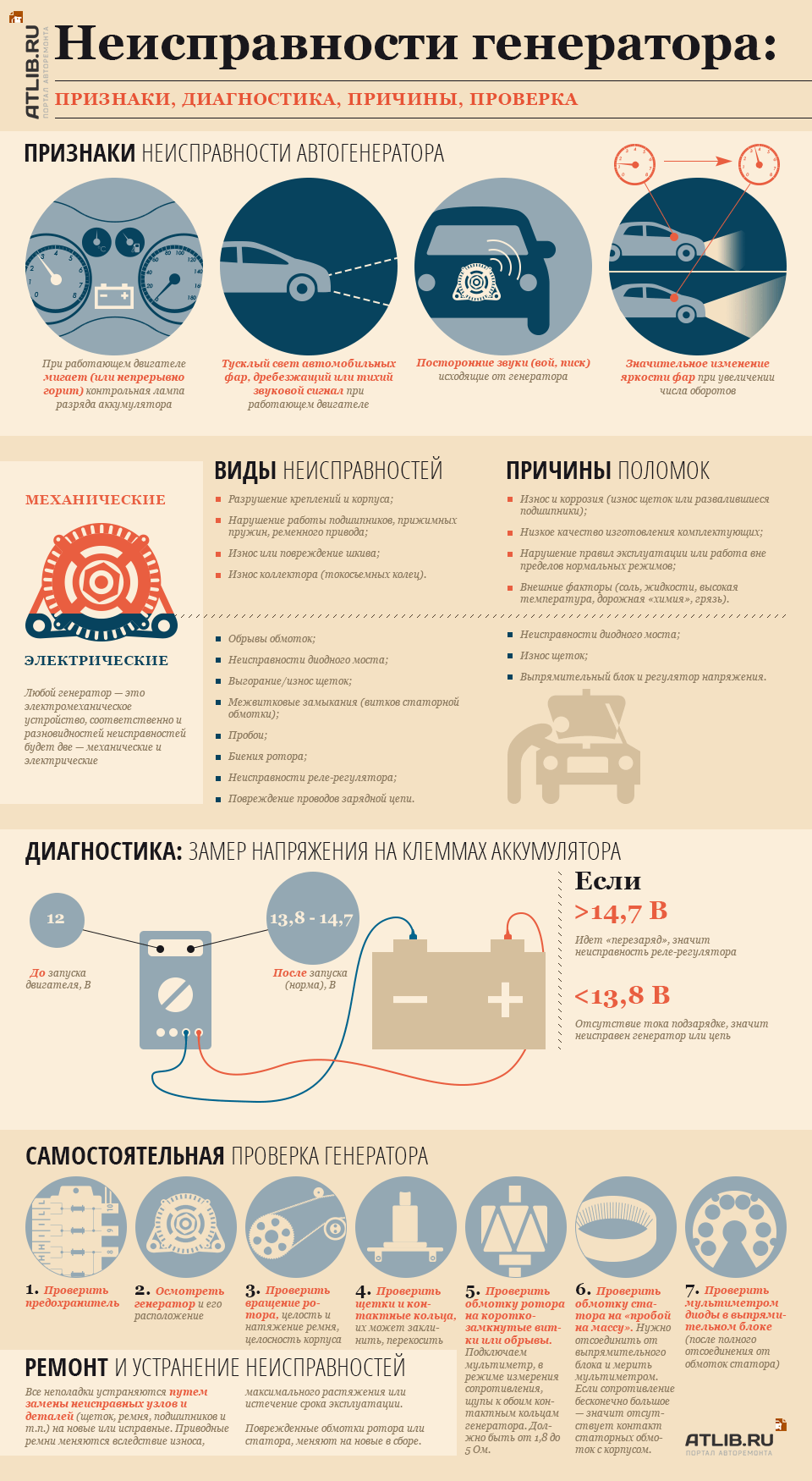

Due to the fact that any generator is an electromechanical device, there will be two types of malfunctions, respectively - mechanical и power.

The first include the destruction of fasteners, housing, malfunction of bearings, hold-down springs, belt drive and others not related to the electrical part of the breakdown.

Electrical faults include breaks in the windings, breakdowns of the diode bridge, burnout / wear of the brushes, interturn short circuits, breakdowns, rotor beats, breakdowns of the relay-regulator.

Often, symptoms indicating a characteristic faulty generator may also appear as a result of completely different problems. As an example, a bad contact in the fuse socket of the generator excitation circuit will indicate a breakdown of the generator. The same suspicion may arise due to burnt contacts in the ignition lock housing. Also, the constant burning of the generator failure indicator lamp can be caused by a relay failure, the blinking of this switching lamp may indicate a generator failure.

The main signs of a breakdown of the oscillator:

- When the internal combustion engine is running, the battery discharge indicator lamp flashes (or lights up continuously).

- Rapid discharge or recharge (boil-off) of the battery.

- Dim light of machine headlights, rattling or quiet sound signal when the engine is running.

- Significant change in the brightness of the headlights with an increase in the number of revolutions. This can be permissible when increasing the speed (overgassing) from the idle mode, but the headlights, having lit up brightly, should not increase their brightness further, remaining at the same intensity.

- Extraneous sounds (howl, squeak) emanating from the generator.

the tension and general condition of the drive belt must be regularly monitored. Cracks and delaminations require immediate replacement.

Alternator repair kits

In order to eliminate the indicated breakdowns of the generator, it will be necessary to carry out repairs. Starting to search for a generator repair kit on the Internet, you should prepare for disappointment - the kits offered usually contain washers, bolts and nuts. And sometimes you can return the generator to working capacity only by replacing - brushes, a diode bridge, a regulator ... Therefore, a brave man who decides to repair makes an individual repair kit from those parts that fit his generator. It looks something like the table below, using the example of a pair of generators for the VAZ 2110 and Ford Focus 2.

| Generator KZATE 9402.3701-03 | ||

|---|---|---|

| Detail | Catalogue number | Price, rub.) |

| Brushes | 1127014022 | 105 |

| Voltage regulator | 844.3702 | 580 |

| Diode bridge | BVO4-105-01 | 500 |

| Подшипники | 6303 and 6203 | 345 |

| Alternator Bosch 0 986 041 850 | ||

|---|---|---|

| Detail | Catalogue number | Price, rub.) |

| Brushes | 140371 | 30 |

| Brush holder | 235607 | 245 |

| Voltage regulator | IN6601 | 1020 |

| Diode bridge | INR431 | 1400 |

| Подшипники | 140084 and 140093 | 140 / 200 rubles |

Fault Diagnosis

On modern cars, the use of the "old-fashioned" diagnostic method by dropping the battery from the battery terminal can also lead to serious damage to many of the car's electronic systems. Significant voltage drops on the vehicle's on-board network can disable almost all on-board electronics. That is why modern generators are always checked only by measuring the voltage in the network or diagnosing the most removed node on a special stand. First, the voltage at the battery terminals is measured, the internal combustion engine is started and readings are taken already with the engine running. Before starting, the voltage should be about 12 V, after starting - from 13,8 to 14,8 V. An upward deviation indicates that there is a "recharge", which implies a breakdown of the relay-regulator, to a smaller one - that no current is flowing. The absence of charging current indicates generator breakdown or chains.

Causes of breakdowns

Common causes of generator malfunctions It's just wear and tear and corrosion. Almost all mechanical failures, whether it be worn brushes or collapsed bearings, are the result of long operation. Modern generators are equipped with closed (maintenance-free) bearings, which simply need to be replaced after a certain period or mileage of the car. The same applies to the electrical part - often the components must be replaced entirely.

also the reasons can be:

- poor quality of manufacturing of components;

- violation of operating rules or work outside the limits of normal modes;

- external causes (salt, liquids, high temperature, road chemicals, dirt).

Generator self check

The easiest way is to check the fuse. If it is in good working order, the generator and its location are inspected. Check the free rotation of the rotor, the integrity of the belt, wires, housing. If nothing aroused suspicion, the brushes and slip rings are checked. In the process of operation, the brushes inevitably wear out, they can get jammed, skewed, and the grooves of the slip rings become clogged with graphite dust. A clear sign of this is excessive sparking.

Cases of complete wear or breakdown of both bearings and stator breakdown are not uncommon.

The most common mechanical problem in a generator is bearing wear. A sign of this breakdown is a howl or whistle during the operation of the unit. Of course, the bearings should be replaced immediately or attempted to be rebuilt with cleaning and lubrication. A loose drive belt can also cause the alternator to run poorly. One of the signs may be a high-pitched whistle from under the hood when the car is accelerating or accelerating.

To check the rotor field winding for short-circuited turns or breaks, you need to connect a multimeter, switched to resistance measurement mode, to both slip rings of the generator. Normal resistance is 1,8 to 5 ohms. The reading below indicates the presence of a short circuit in the turns; above - a straight winding break.

To check the stator winding for "breakdown to ground", they must be disconnected from the rectifier unit. With the resistance readings given by the multimeter, which are of infinite value, there is no doubt about the absence of contact between the stator windings and the case ("ground").

A multimeter is used to test the diodes in the rectifier unit (after completely disconnecting from the stator windings). The test mode is "diode test". The positive probe is connected to the plus or minus of the rectifier, and the negative probe is connected to the phase output. After that, the probes are interchanged. If at the same time the readings of the multimeter are very different from the previous ones, the diode is working, if they do not differ, it is faulty. also one sign indicating the imminent "death" of the diode bridge of the generator is the oxidation of the contacts, and the reason for this is overheating of the radiator.

Repair and troubleshooting

All mechanical problems are eliminated by replacing faulty assemblies and parts (brushes, belt, bearings, etc.) for new or serviceable ones. On older models of generators, slip rings are often required to be machined. Drive belts are replaced due to wear, maximum stretch or the end of their service life. Damaged rotor or stator windings, they are currently being replaced with new ones as an assembly. Rewinding, although it is found among the services of car repairmen, is less and less common - it is expensive and impractical.

And that’s all electrical problems with a generator you need decide due to verificationlike others chain elements (namely, the battery), so and precisely its details and output voltage. One of the most common problems car owners face is overcharge, or vice versa, generator low voltage. Checking and replacing the voltage regulator or diode bridge will help eliminate the first breakdown, and it will be a little more difficult to deal with the issuance of low voltage. There can be several reasons why the generator produces low voltage:

- increased load on the on-board network by consumers;

- breakdown of one of the diodes on the diode bridge;

- failure of the voltage regulator;

- slippage of the V-ribbed belt (due to weak tension)

- poor contact of the ground wire on the generator;

- short circuit;

- planted battery.

infographics