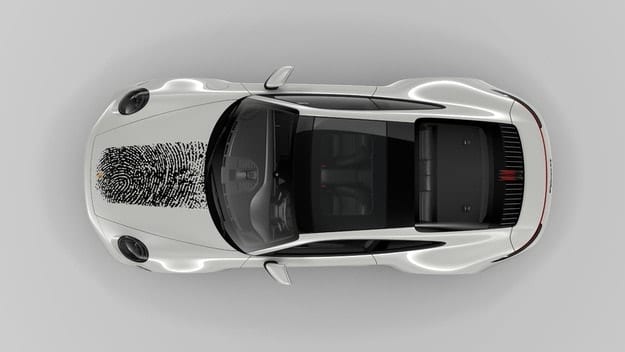

Porsche as private as a fingerprint

Content

German company has developed an innovative method of painting by printing the body

It is unlikely that any of the Porsche is the same as someone else. But from now on, 911 can be as unique as the papillary lines of a human finger. Using the innovative direct printing method developed by Porsche, graphic elements with the highest image quality can now be printed on painted body parts. Initially, customers who purchase the new 911 may have a special cover with a design based on their own fingerprint. In the medium term, other customer-specific projects will become available. This service is available at Porsche Centers, which contact customer advisors at Exclusive Manufaktur in Zuffenhausen. Consultants discuss the entire process with the client, from fingerprinting to picking a car.

“Individuality is very important to Porsche customers. And no design can be more personal than your own print,” says Alexander Fabig, VP Customization and Classics. “Porsche has pioneered personalization and has developed a direct printing method with partners. We are particularly proud to have developed a completely new offering based on new technologies. The key to this is the different disciplines working together in the project team. The so-called "technological cell" was created for the project in the paint shop of the Zuffenhausen training center. It is here that new software and hardware, as well as related painting and production processes, are developed and tested. The decision to place the technology cell in the learning center was deliberate: among other things, it will be used to familiarize students with innovative technologies.

Direct printing allows you to make designs that are not possible with conventional inks. In terms of looks and new feel, the new technology is clearly superior to films. The principle of operation is similar to that of an inkjet printer: when using a printhead, ink is applied to XNUMXD components automatically and without overspray. “The possibility of individually controlling the nozzles makes it possible to apply every drop of paint in a targeted manner,” explains Christian Will, Vice President Production Development at Porsche AG. “The difficulty comes from the need to harmonize three technologies: robotic technology (control, sensors, programming), application technology (print head, graphics processing) and coloring technology (application process, ink).”

Porsche Exclusive Manufactory

If the customer decides to improve their 911 using direct printing, Porsche Exclusive Manufaktur specialists will disassemble the cover after mass production. Client biometric data is processed to ensure that it cannot be used for unauthorized purposes. The whole process takes place in direct communication with the owner, who has a complete overview of how his personal data is used, and is also integrated into the process of creating his own print schedule. After the robot has painted a unique design, a transparent layer is applied and then the lid is polished to a high gloss to meet the highest quality standards. The extended component is then reinstalled. The cost of the service in Germany is 7500 euros (including VAT) and will be provided by Porsche Exclusive Manufaktur upon request from March 2020.

Porsche Exclusive Manufaktur creates many personal cars for customers through a combination of sophisticated manufacturing and high technology. 30 highly qualified employees pay all attention to every detail and allocate the necessary time to achieve the perfect result thanks to hard work. Professionals can use an extremely wide range of visual and technical settings to improve the exterior and interior. In addition to special vehicles for customers, Porsche Exclusive Manufaktur also produces limited small series as well as publications that combine high-quality materials with modern production technologies to create a harmonious overall concept.