Advantages and construction principle of McPherson type suspension

Content

For budget cars, it is not so important to provide ideal performance in terms of comfort, response to control or operational regulation, as to minimize the complexity and physical volume of the equipment of the suspension units. Without simplifying it at the same time to the complete loss of the competitiveness of the car. The problem can be considered solved if you look at the device of the most popular suspension in the world for cars - McPherson-type telescopic struts.

How did the candlestick come about?

With the exception of early experiments on sports cars of the first half of the last century, the first serious appearance of a new type was the 50s, when one of Ford's engineers patented a design named after him. And he not only received a patent for another exotic, but achieved its application in the serial Ford Consul. For that conservative time in the US automotive industry, the phenomenon became unusual. The name of the developer was Earl McPherson.

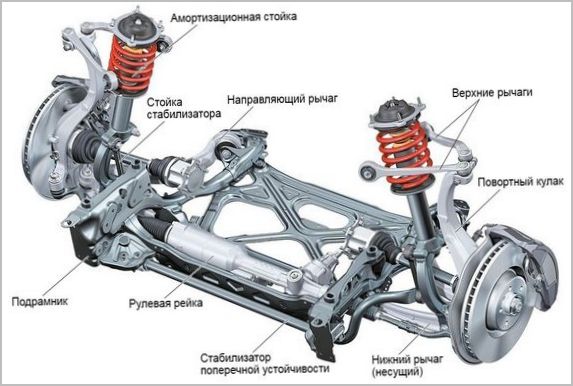

Suspension device

The main feature was the use of a single design that integrates all three components of the suspension unit - an elastic element, a damper and a guide vane. All this came together in the form of a single rack, which only had to be fixed from above to the body and from below to a single triangular lever. During operation, the angle of the axis of the rack changed, so it is sometimes called a swinging candle.

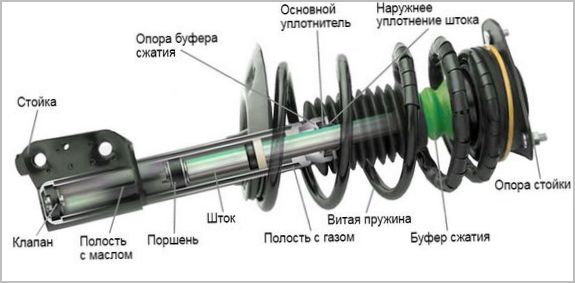

The basic structural element of the strut is an enlarged and reinforced body of a telescopic shock absorber with a pivot arm fixed on it, a lower spring stop and a bracket for bolting to the steering knuckle. The rod extending from the top of the shock absorber with a threaded tip with a nut was connected to the upper support of the rack. The spring covered the body from the outside.

The top support performed several functions:

- fastening the suspension strut at the top point to the body through the power cup above the spar;

- damping of vibrations and small shocks coming through the spring and rod by means of a rubber insert in the support hinge;

- stop for the upper coil of a cylindrical or barrel-shaped spring, with the lower end resting against the shock absorber body, both coils lie on absorbent elastic cushions;

- rotation of the stem and spring under the action of the steering due to the presence of a thrust rolling bearing:

- the presence of a plane for the operation of an elastic bump put on the shock absorber rod.

From below, the rack through the knuckle was attached to the lever with the help of a lower ball joint. This ensures the freedom of the working strokes of the suspension and the possibility of turning the steered wheels. The lever is attached to the body or subframe through rubber-metal silent blocks.

The suspension, like many others, is complemented by an anti-roll bar connected through struts with ball ends or rubber bushings.

work Features

The position of the rack relative to the body determines the angles of the wheels, except for convergence, which is provided by adjusting the length of the steering rods. Therefore, the slopes of the body in the longitudinal and transverse planes are selected when setting up the suspension, adjustments are also provided by the selection of washers and eccentric bolts for attaching to the fist.

The working travel of the suspension is limited by an elastic bumper put on the rod, and the rebound travel is limited by the internal buffer of the shock absorber. Silent blocks and ball bearings are calculated in such a way that they do not collapse with the full stroke of the rod.

Pushing and pulling forces are transmitted to the body through a rigid triangular lever. Sometimes it is performed in the form of a transverse link with one silent block to the body and is complemented by a longitudinal stretch. On the reverse side, the reactive force is transmitted through the power telescope of the shock absorber. Inside the strut is the usual hydraulic damper set of damper fluid, pistons, valves and throttling holes. Recently, almost all racks contain pressurized gas to prevent foaming and boiling when overheated.

Advantages and disadvantages of candle suspension

The main reason for such a wide distribution is the excellent compactness characteristics. Reducing the size of the wheel arches, where the suspension units are located, ultimately leads to an increase in the useful volume of the body to accommodate passengers and cargo. There are other benefits too:

- the suspension is ideally combined with the front-wheel drive scheme of compact cars with a transverse arrangement of a monoblock engine and transmission;

- McPherson-type rear suspension allows you to significantly expand the luggage compartment and lower its floor;

- the suspension consists of a minimum number of parts, which reduces the cost of production;

- for the same reason, it is reliable and easy to repair;

- does not cause complaints about the excess of unsprung masses, although it does not lead in this indicator;

- when used on the rear axle, it easily allows you to organize a fully steerable chassis.

Simplicity cannot but affect the presence of disadvantages:

- the suspension cannot provide an ideal wheel trajectory and a stable contact patch;

- an undesirable friction force develops in the stand telescope;

- the upper support poorly isolates the body from the transmission of small road bumps;

- the glass of the body is heavily loaded, the whole structure does not have a margin of safety.

All this quite clearly defines the scope - these are the most common budget cars of small and medium class. It is rarely used on large cars of the premium segment, even if shock absorbers combined with a spring are installed there, then all this is complemented by a complicated guide vane and means of increasing comfort. But this does not prevent the MacPherson type suspension from being the most widely used type in the world.