Application of urea in diesel engine

Content

Modern environmental regulations set strict limits on the emission values of pollutants in the exhaust gases of a diesel engine. This forces engineers to look for new solutions to meet the standards. One of these was the use of urea for diesel fuel in the SCR (Selective Catalytic Reduction) exhaust aftertreatment system. Daimler engines that use this technology are called Bluetec.

What is the SCR system

The Euro 6 environmental protocol has been in force in 28 EU countries since 2015. Under the new standard, diesel car manufacturers have strict requirements because diesel engines cause huge damage to the environment and human health, emitting soot and nitrogen oxides into the atmosphere.

While the use of a three-way catalytic converter is sufficient to clean the exhaust gases of a gasoline engine, a more sophisticated device for neutralizing toxic compounds in the exhaust gases is necessary for a diesel engine. The efficiency of cleaning CO (carbon monoxide), CH (hydrocarbons) and soot particles from diesel engine exhaust gases increases at high combustion temperatures, while NOx, on the contrary, decreases. The solution to this problem was the introduction of an SCR catalyst into the exhaust system, which uses diesel urea as the basis for the decomposition of toxic compounds of nitrogen oxide (NOx).

In order to reduce harmful emissions, engineers have developed a special diesel cleaning system - Bluetec. The complex consists of three complete systems, each of which filters toxic compounds and breaks down harmful chemical compounds:

- Catalyst - neutralizes CO and CH.

- Particulate filter - traps soot particles.

- SCR catalytic converter - Reduces NOx emissions with urea.

The first cleaning system was used on Mercedes-Benz trucks and cars. Today, many manufacturers are converting their vehicles to a new cleaning system and using urea in diesel engines to meet stringent environmental control requirements.

Technical urea AdBlue

The end product of mammalian metabolism, urea, has been known since the XNUMXth century. Carbonic acid diomide is synthesized from inorganic compounds and is widely used in agriculture. In the automotive industry, a solution of Adblue technical fluid as an active agent in the purification of toxic exhaust gases from nitrogen oxides.

Adblue is 40% urea and 60% distilled water. The composition is injected into the SCR system at the nozzle through which the exhaust gases pass. A decomposition reaction occurs, in which nitric oxide breaks down into harmless nitrogen and water molecules.

Technical urea for diesel - Adblue has nothing to do with urea urea, which is used in the agro-industrial sector and in pharmacology.

Edblue in diesel engine

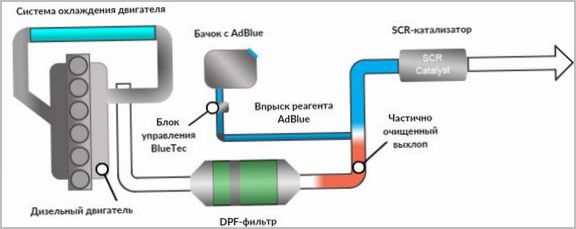

A liquid exhaust aftertreatment system, or SCR converter, is a closed system through which soot-free diesel exhaust flows. Adblue liquid is poured into a self-contained tank and injected into the exhaust pipe in a measured dose before entering the converter.

The mixed gas enters the SCR neutralization unit, where a chemical reaction takes place to decompose nitric oxide at the expense of ammonia in urea. In combination with nitric oxide, ammonia molecules break it down into components that are harmless to humans and the environment.

After a complete cleaning cycle, the minimum amount of pollutants is emitted into the atmosphere, the emission parameter complies with the Euro-5 and Euro-6 protocols.

The principle of operation of the diesel exhaust purification system

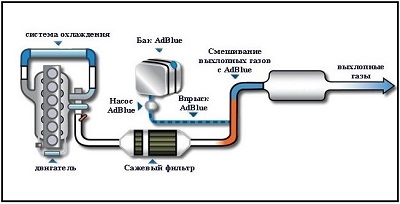

A complete diesel engine aftertreatment system consists of a catalytic converter, a particulate filter and an SCR system. The principle of operation of cleaning in stages:

- Exhaust gases enter the catalytic converter and particulate filter. Soot is filtered, fuel particles are burned off, and carbon monoxide and hydrocarbons are removed.

- The injector is used to inject a certain amount of AdBlue into the connection between the diesel particulate filter and the SCR catalytic converter. Urea molecules decompose into ammonia and isocyanic acid.

- Ammonia combines with nitrogen oxide, the most harmful component of used diesel fuel. Molecules are split, which leads to the formation of water and nitrogen. Harmless exhaust gases are released into the atmosphere.

Composition of urea for diesel

Despite the apparent simplicity of diesel engine fluid, it is impossible to prepare urea on your own using organic fertilizer. The formula of the urea molecule (NH2) 2CO, is physically an odorless white crystal, soluble in water and polar solvents (liquid ammonia, methanol, chloroform, etc.).

For the European market, the fluid is produced under the supervision of the VDA (German Automobile Industry Association), which issues licenses to manufacturing companies, some of which supply fluid for the domestic market.

In Russia, counterfeiting under the AdBlue brand is more than 50%. So, when buying urea for a Russian-made diesel engine, you must be guided by the marking “ISO 22241-2-2009 Compliance”.

Advantages and disadvantages

The advantages of using urea are obvious - only with this reagent the exhaust gas treatment system of the SCR diesel engine can fully function and meet the requirements of the Euro 6 Standard.

In addition to protecting the environment, the benefits of urea purification include the following points:

- its consumption for cars is only 100 g per 1000 km;

- the SCR system is integrated into modern diesel vehicles;

- in some countries the tax on the use of the vehicle is reduced if a urea cleaning system is installed, and there is no risk of a fine.

Unfortunately, the system also has disadvantages:

- the freezing point of urea is about -11 °C;

- the need for regular refueling;

- the cost of the car increases;

- a large amount of fake Adblue liquid;

- increased requirements for fuel quality;

- costly repairs to system components.

The integrated urea scrubbing system built into diesel vehicles remains the only way to reduce toxic emissions. Difficulties in operation, high cost of truck reagents, poor quality fluid and diesel fuel mean that many drivers choose to disable the system and install emulators.

However, it is important to understand that urea remains the only diesel chemical that prevents the release of nitric oxide into the environment, which can lead to cancer.