The use of a transfer case in all-wheel drive

Content

The huge popularity that SUVs and crossovers have gained recently is not accidental. Four-wheel drive gives the driver the ability to drive around the city and over rough terrain. In such a car, the transfer case is designed in such a way as to fully realize the advantages of all-wheel drive.

The purpose of the transfer case

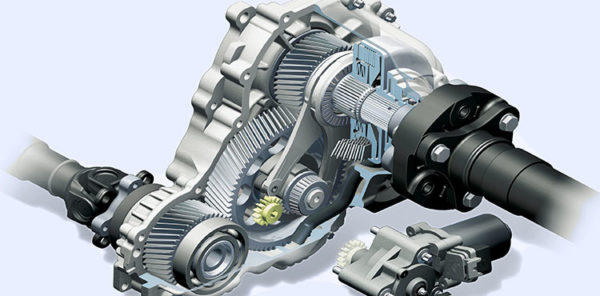

In single drive vehicles, the torque generated by the engine and the converted gearbox is transmitted directly to the drive wheels. If the car has four-wheel drive, for the most rational use of torque, it is necessary to distribute between the front and rear axles. In addition, from time to time it becomes necessary to change the amount of torque transmitted to a particular axle during movement.

The transfer case is responsible for the distribution of engine power between the front and rear axles. Like a gearbox, it is able to increase the torque value to a certain extent, which is especially important when operating a car in difficult off-road conditions.

Sometimes this mechanism performs special functions on special equipment (fire engines, agricultural and construction equipment). The task of the transfer case is to transfer part of the torque to special equipment: a fire pump, a cable winch, a crane mechanism, etc.

The design of the dispenser

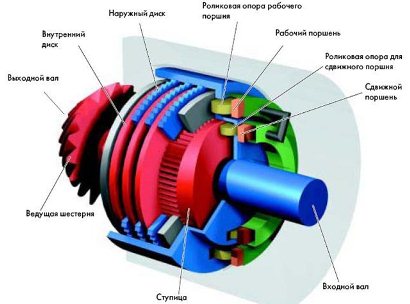

The transfer case, sometimes referred to simply as the "transfer case", is installed between the shafts and the gearbox leading to the axles. Despite the huge variety of designs, some parts of the transfer case are available on any model:

- drive shaft (transmits torque from the gearbox to the transfer case);

- locking mechanism and center differential;

- gear or chain reduction gear;

- actuator (responsible for turning on the lock);

- cardan shafts for driving the front and rear axles;

- a synchronizer that allows you to turn on the lower row in motion.

The transfer case is a housing that includes the engine drive shaft, and two cardan shafts go to the front and rear axles. The design of the transfer case is similar to the design of the gearbox: its body is a closed crankcase, the oil bath of which provides lubrication of the differential and the locking mechanism. To switch, use the lever or buttons in the cabin.

The principle of operation of the transfer case

The main function of the transfer case is to connect or disconnect one of the bridges. In the design of classic SUVs and four-wheel drive trucks, the torque is invariably transferred to the rear drive axle. The front axle, in order to save fuel and the life of the nodes, was connected only to overcome difficult sections of the road or in difficult road conditions (rain, ice, snow). This principle is preserved in modern cars, with the only difference that the front axle is now invariably the leading one.

The change in torque, its distribution between all drive axles, is the second most important function of the transfer case. The center differential distributes torque between the front and rear axles, while they can receive equal power (symmetrical differential) or divided by a certain proportion (asymmetrical differential).

The center differential allows the axles to rotate at different speeds. This is necessary when driving on well-paved roads to reduce tire wear and save fuel. At the moment when the car leaves the road, and you need to make the most of all-wheel drive, the center differential lock is activated, the axles are rigidly connected to each other and can only rotate at the same speed. Thanks to the prevention of slippage, this design increases off-road flotation.

It should be emphasized that the differential lock function is available only in a small number of transfer cases installed on classic SUVs, special vehicles and military trucks. The parquet crossovers and SUVs that are common in our time are not designed for such serious off-road driving, therefore, in order to reduce the cost, they are deprived of this function.

Variety of center differential

The transfer cases use three different center differential lock systems that are installed on vehicles with off-road qualities.

Friction multi-plate clutch. The most modern type of differential lock in the transfer case. The controlled compression force of the set of friction discs used in the clutch allows the torque to be distributed along the axles depending on the specific road conditions. Under normal road conditions, the axles are loaded equally. If one of the axles begins to slip, the friction discs are compressed, partially or completely blocking the center differential. Now the axle, which perfectly “clings to the road”, receives more torque from the engine. To do this, the actuator sends a command to the electric motor or hydraulic cylinder.

Viscous coupling or viscous coupling. An outdated but cheap and easy to use diff lock. It consists of a set of discs placed in a housing filled with silicone fluid. The discs are connected to the wheel hubs and the clutch housing. As the speed of the bridges starts to change, the silicone becomes more viscous, blocking the discs. The disadvantages of the outdated design include a tendency to overheat during operation and untimely exposure.

Differential Torsen due to its limited strength, it is used in "parquet" SUVs and off-road station wagons. Like a viscous coupling, it transmits torque to a shaft that slips less. The Thorsen actuator is capable of distributing no more than 80% of the thrust to the loaded axle, while the sliding axle will in any case have at least 20% of the torque. The design of the differential consists of worm gears, due to the friction of which a lock is formed.

How to operate the transfer case

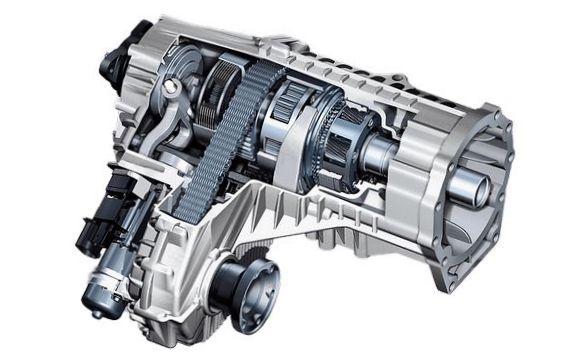

Old SUVs, trucks and special vehicles usually have a manual (mechanical) "transfer case" control. To engage or disengage one of the axles, as well as to engage the differential or low range, a lever is used, usually located on the cab floor next to the gear lever. To turn it on, it is necessary from time to time to completely stop the car.

Younger models have electric manual control and all transfer case modes are selected using buttons on the panel. If the "razdatka" has a synchronizer, you do not need to stop the car.

In modern cars, a transfer case is used. When automatic mode is selected, the on-board computer detects axle slip and then redirects the torque. If necessary, activates the differential lock. The driver can turn off the automation and do all the work on the go himself. There is no control lever.

All types of crossovers and station wagons have a fully automated transfer case control mechanism. The driver does not have the opportunity to independently control the mechanism, since all decisions are made by a computer.