The principle of operation of an automatic transmission

Content

- What is automatic transmission and the history of its creation

- Automatic transmission device

- The principle of operation and service life of automatic transmission

- Varieties of automatic transmission

- How to use an automatic transmission

- The difference between automatic transmission in rear-wheel drive and front-wheel drive cars

The dynamics of the car depends on the type of transmission used. Machine manufacturers are constantly testing and implementing new technologies. However, many motorists operate vehicles on mechanics, believing that in this way they can avoid the high financial costs of repairing automatic transmissions. Nevertheless, the automatic transmission is lighter and more convenient to use, it is indispensable in a densely populated city. Having only 2 pedals in an automatic car makes it the best mode of transport for inexperienced drivers.

What is automatic transmission and the history of its creation

An automatic transmission is a transmission that, without the participation of a motorist, selects the optimal gear ratio according to the conditions of movement. The result is a smooth ride of the vehicle and comfort for the driver himself.

History of invention

The basis of the machine is a planetary gearbox and a torque converter, which was created by the German Hermann Fittenger in 1902. The invention was originally intended to be used in the field of shipbuilding. In 1904, the Startevent brothers from Boston presented another version of the automatic transmission, consisting of 2 gearboxes.

The first cars on which planetary gearboxes were installed were produced under the name Ford T. The principle of their operation was as follows: the driver switched the driving mode using 2 pedals. One was responsible for upshifting and downshifting, the other provided reverse movement.

In the 1930s, General Motors designers released a semi-automatic transmission. The machines still provided for the clutch, but the hydraulics controlled the planetary mechanism. Around the same time, Chrysler engineers added a hydraulic clutch to the box. The two-speed gearbox was replaced by an overdrive - overdrive, where the gear ratio is less than 1.

The first automatic transmission appeared in 1940 at General Motors. It combined a hydraulic clutch and a four-stage planetary gearbox, and automatic control was achieved through hydraulics.

Pros and cons of automatic transmission

Each type of transmission has fans. But the hydraulic machine does not lose its popularity, since it has undoubted advantages:

- gears are activated automatically, which contributes to full concentration on the road;

- the process of starting the movement is as easy as possible;

- the undercarriage with the engine is operated in a more gentle mode;

- the cross-country ability of cars with automatic transmission is constantly improving.

Despite the presence of advantages, motorists reveal the following disadvantages in the operation of the machine:

- there is no way to quickly accelerate the car;

- engine throttle response is lower than that of a manual transmission;

- transport cannot be started from a pusher;

- the car is difficult to tow;

- improper use of the box leads to breakdowns;

- Automatic transmissions are expensive to maintain and repair.

Automatic transmission device

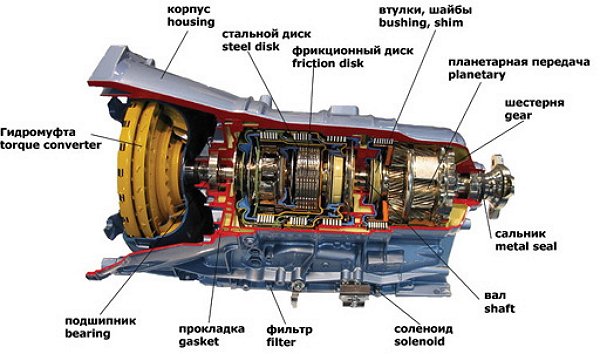

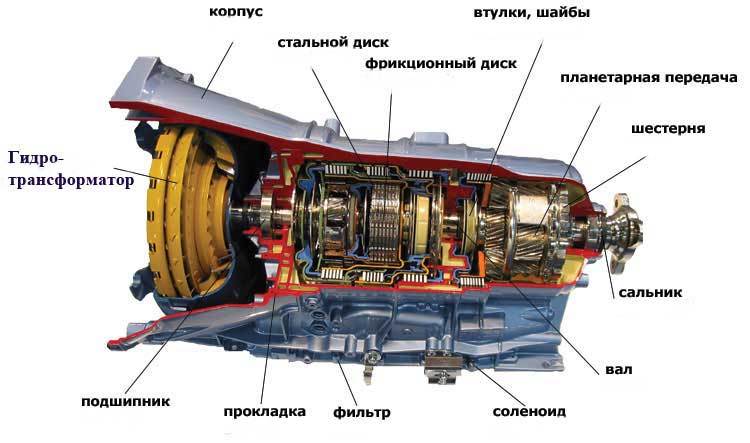

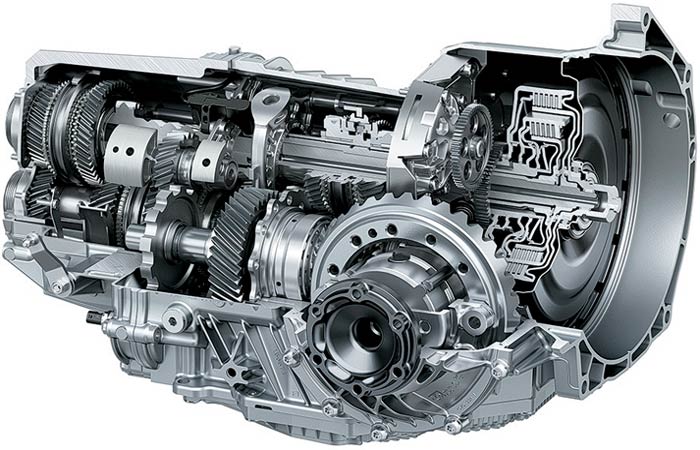

There are 4 main components in a classic slot machine:

- Hydraulic transformer. In the context, it looks like a bagel, for which it received the corresponding name. The torque converter protects the gearbox in the event of rapid acceleration and engine braking. Inside is gear oil, the flows of which provide lubrication to the system and create pressure. Due to it, a clutch is formed between the motor and the transmission, the torque is transmitted to the chassis.

- Planetary reductor. Contains gears and other working elements that are driven around one center (planetary rotation) using a gear train. The gears are given the following names: central - solar, intermediate - satellites, external - crown. The gearbox has a planetary carrier, which is designed to fix the satellites. To shift gears, some gears are locked while others are set in motion.

- Brake band with a set of friction clutches. These mechanisms are responsible for the inclusion of gears, at the right time they block and stop the elements of the planetary gear. Many do not understand why a brake band is needed in an automatic transmission. It and the clutch are switched on and off in sequence, which leads to the redistribution of torque from the engine and ensures smooth gear changes. If the tape is not adjusted correctly, jerks will be felt during movement.

- Control system. It consists of a gear pump, an oil sump, a hydraulic unit and an ECU (electronic control unit). The hydroblock has control and management functions. The ECU receives data from various sensors about the speed of movement, the choice of the optimal mode, etc., thanks to this, the automatic transmission is controlled without the participation of the driver.

The principle of operation and service life of automatic transmission

When the engine starts, transmission oil enters the torque converter, the pressure inside increases, and the centrifugal pump blades begin to rotate.

When the driver shifts the lever and presses the pedal, the speed of the pump vanes increases. The speed of the swirling oil flows increases and the turbine blades start. The liquid is alternately transferred to the reactor and returned back to the turbine, providing an increase in its efficiency. The torque is transferred to the wheels, the vehicle starts to move.

As soon as the required speed is reached, the bladed central turbine and the pump wheel will begin to move in the same way. The oil whirlwinds hit the reactor wheel from the other side, since the movement can only be in one direction. It starts spinning. If the car goes uphill, then the wheel stops and transfers more torque to the centrifugal pump. Reaching the desired speed leads to a gear change in the planetary gear set.

At the command of the electronic control unit, the braking band with friction clutches slows down the low gear, which leads to an increase in the movement of oil flows through the valve. Then the overdrive is accelerated, its change is made without loss of power.

If the machine stops or its speed decreases, then the pressure of the working fluid also decreases, and the gear shifts down. After the engine is turned off, the pressure in the torque converter disappears, which makes it impossible to start the car from the pusher.

The weight of the automatic transmission reaches 70 kg in a dry state (there is no hydraulic transformer) and 110 kg when filled. In order for the machine to function normally, it is necessary to control the level of the working fluid and the correct pressure - from 2,5 to 4,5 bar.

Box resource may vary. In some cars, it serves about 100 km, in others - more than 000 km. The service period depends on how the driver monitors the condition of the unit, whether it replaces consumables on time.

Varieties of automatic transmission

According to technicians, the hydromechanical automatic transmission is represented only by the planetary part of the assembly. After all, it is responsible for shifting gears and, together with the torque converter, is a single automatic device. The automatic transmission includes a classic hydraulic transformer, a robot and a variator.

Classic automatic transmission

The advantage of a classic machine is that the transmission of torque to the chassis is provided by an oily fluid in the torque converter.

Robotic checkpoint

It is a kind of alternative to mechanics, only in the design there is a double clutch controlled by electronics. The main advantage of the robot is fuel economy. The design is equipped with software, the work of which is to rationally determine the torque.

The box is called adaptive, because. it is able to adapt to the driving style. Most often, the clutch breaks in the robot, because. it cannot carry heavy loads, such as when riding in difficult terrain.

Variable speed drive

The device provides a smooth stepless transmission of the torque of the chassis of the car. The variator reduces gasoline consumption and increases dynamics, provides the engine with a gentle operation. Such an automated box is not durable and does not withstand heavy loads. Inside the unit, the parts constantly rub against each other, which limits the life of the variator.

How to use an automatic transmission

Service station locksmiths claim that most often automatic transmission breakdowns appear after careless use and untimely oil changes.

Modes of operation

There is a button on the lever that the driver must press to select the desired mode. The selector has several possible positions:

- parking (P) - the drive axle is blocked together with the gearbox shaft, it is customary to use the mode in conditions of prolonged parking or warming up;

- neutral (N) - the shaft is not fixed, the machine can be carefully towed;

- drive (D) - the movement of vehicles, gears are selected automatically;

- L (D2) - the car moves in difficult conditions (off-road, steep descents, ascents), the maximum speed is 40 km / h;

- D3 - gear reduction with a slight descent or ascent;

- reverse (R) - reverse;

- overdrive (O / D) - if the button is active, then when a high speed is set, fourth gear is switched on;

- PWR - "sport" mode, provides improved dynamic performance by increasing gears at high speeds;

- normal - smooth and economical ride;

- manu - gears are engaged directly by the driver.

How to start a car automatically

The stable operation of the automatic transmission depends on the correct start. To protect the box from illiterate impact and subsequent repair, several degrees of protection have been developed.

When starting the engine, the selector lever must be in the "P" or "N" position. These positions allow the protection system to skip the signal to start the engine. If the lever is in a different position, the driver will not be able to turn on the ignition, or nothing will happen after turning the key.

It is better to use the parking mode to start the movement correctly, because with the “P” value, the drive wheels of the car are blocked, which prevents it from rolling. The use of the neutral mode allows for emergency towing of vehicles.

Most cars with automatic transmission will start not only with the correct position of the lever, but also after depressing the brake pedal. These actions prevent accidental rollback of the vehicle when the lever is set to "N".

Modern models are equipped with a steering wheel lock and anti-theft lock. If the driver has completed all the steps correctly, and the steering wheel does not move and it is impossible to turn the key, then this means that the automatic protection is turned on. To unlock it, you must once again insert and turn the key, as well as rotate the steering wheel in both directions. If these actions are performed synchronously, then the protection is removed.

How to drive an automatic transmission and what not to do

To achieve a long service life of the gearbox, it is necessary to correctly set the mode depending on the current conditions of movement. To operate the machine correctly, the following rules must be observed:

- wait for a push that notifies of the full engagement of the transmission, only then you need to start moving;

- when slipping, it is necessary to shift to a lower gear, and when working with the brake pedal, make sure that the wheels rotate slowly;

- the use of different modes allows for engine braking and acceleration limitation;

- while towing vehicles with the engine running, a speed limit of up to 50 km / h must be observed, and the maximum distance must be less than 50 km;

- you cannot tow another car if it is heavier than a car with automatic transmission, when towing, you must put the lever on "D2" or "L" and drive no more than 40 km / h.

To avoid costly repairs, drivers should not:

- move in parking mode;

- descend in neutral gear;

- try to start the engine with a push;

- put the lever on "P" or "N" if you need to stop for a while;

- turn on reverse from position “D” until the movement stops completely;

- on a slope, switch to the parking mode until the car is put on the handbrake.

To start moving downhill, you must first depress the brake pedal, then release the handbrake. Only then is the driving mode selected.

How to operate automatic transmission in winter

In cold weather, there are often problems with machines. To save the resource of the unit in the winter months, drivers should adhere to the following recommendations:

- After turning on the engine, warm up the box for several minutes, and before driving, press and hold the brake pedal and switch all modes. These actions allow the transmission oil to warm up faster.

- During the first 5-10 km, you do not need to accelerate sharply and slip.

- If you need to leave a snowy or icy surface, then you should include a lower gear. Alternately, you need to work with both pedals and carefully drive out.

- The buildup cannot be done, since it adversely affects the hydraulic transformer.

- Dry pavement allows you to downshift and engage semi-automatic mode to stop movement by braking the engine. If the descent is slippery, then you need to use the brake pedal.

- On an icy slope, it is forbidden to press the pedal sharply and allow the wheels to slip.

- In order to gently exit the skid and stabilize the machine, it is recommended to briefly enter the neutral mode.

The difference between automatic transmission in rear-wheel drive and front-wheel drive cars

In a car with front-wheel drive, the automatic transmission has a more compact size and a differential, which is a main gear compartment. In other aspects, the scheme and functionality of the boxes has no differences.