AWS additive. Professional reviews

What is it made of and how does it work?

AWS additive is a nano-composition, which is made on the basis of natural composite minerals. Stands for Anti-Wear Systems. Translated as "anti-wear systems". The mineral, the active component, is ground to a fraction of 10-100 nm. A neutral mineral base was taken as a carrier. The manufacturer is the Russian company ZAO Nanotrans.

The additive is supplied in a package that includes 2 x 10 ml syringes, gloves and long flexible nozzles through which the agent is pumped into the friction unit. The composition can only be purchased through a network of official representatives of the company. There is no original additive in the open sale on the markets.

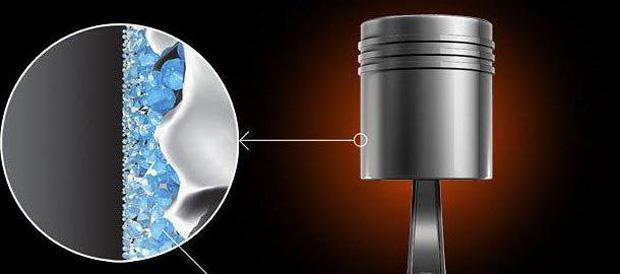

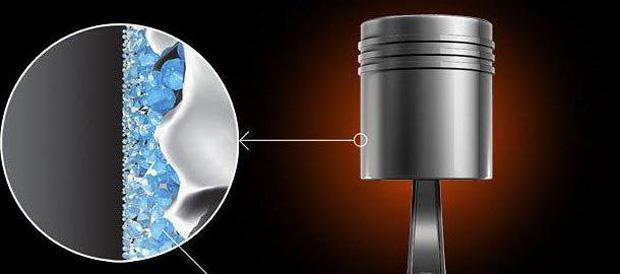

After hitting the friction surface, the composition forms a thin layer, the thickness of which is within 15 microns. The layer has a high hardness (much harder than any known metal) and a low coefficient of friction, which, under good conditions, drops to a record low of only 0,003 units.

The manufacturer promises the following list of positive effects:

- extending the service life of worn units due to the partial restoration of damaged friction pairs;

- formation of a protective layer that reduces the intensity of hydrogen wear;

- increase in the resource of units when using the product from the very beginning of operation;

- increase and equalization of compression in the internal combustion engine cylinders;

- reduction of fuel and oil consumption for waste;

- power gain;

- reduction of noise and vibrations from the operation of the engine, gearbox, power steering, axles and other units.

The severity of this or that effect depends on many factors. And, as the manufacturer says, for different nodes and different operating conditions, one or another beneficial effect will manifest itself to varying degrees.

Instructions for use

First of all, the manufacturer insists on studying the problem, finding out the cause of the failure of a particular node. Since the composition itself is not a panacea, but works purposefully to restore microdamages and non-critical wear in metal friction units. In some cases, the product covers shallow scuff marks.

The composition will not help if there are the following defects:

- critical wear of bearings with the appearance of backlashes and axial movements noticeable during instrumentless diagnostics;

- cracks visible to the naked eye, deep scuffs, shells and chips;

- uniform wear of the metal to the limit state (the composition is not able to build up the surface worked out by hundreds of microns, it only creates a thin layer);

- failures in the operation of control mechanics or electronics;

- non-metallic parts are worn out, for example, valve seals or power steering plastic bushings.

If the problem is just moderately worn friction spots, or if increased protection is required from the first start, AWS additive will help.

Motors are processed twice with an interval of 300-350 km. The additive can be poured into both fresh and partially used oil (but not later than 3 thousand kilometers before replacement) with the engine running. The composition is introduced through the oil dipstick.

For gasoline engines, the proportion is 2 ml of additive per 1 liter of oil. For diesel engines - 4 ml per 1 liter of oil.

After the first filling, the engine should run at idle for 15 minutes, after which it must be stopped for 5 minutes. Next, the motor starts again for 15 minutes, after which it must be allowed to cool for 5 minutes.

This completes the first processing. After a run of 350 km, it is necessary to repeat the processing in a similar scenario. After the second filling, during 800-1000 km of run, the engine must be operated in the break-in mode. The additive works for a year and a half or 100 thousand kilometers, whichever comes first.

Watch this video on YouTube

Professional reviews

More than half of the time AWS is referred to as a “partially working additive” by workshops and garage technicians. But unlike many other formulations, such as ER additives, the effect of using AWS is immediately noticeable. It is difficult to judge the final effectiveness in comparison with other means.

After doing a cycle with starts-stops, already after the first treatment, in almost all cases there is an increase in compression in the cylinders. This is partly due to the effect of rapid decarbonization of the rings and the formation of the first, “rough” layer on the surface of the cylinders.

Noise reduction measurements are freely available on the network. The engine starts to run quieter after using the AWS additive by about 3-4 dB. This seems like a small number, given that the average engine volume is about 60 dB. However, in practice the difference is noticeable.

After opening the motor, which was treated with the AWS additive, the craftsmen note the presence of a yellowish coating on the cylinder walls. This is the cermet. Visually, this layer smoothes the microrelief. The cylinder looks more even, with no visible damage.

Motorists also note a decrease in oil consumption for waste, but not in all cases. If abundant blue or black smoke poured out of the pipe, after treatment with an additive, the intensity of smoke emission often decreases.

It becomes obvious that the AWS additive at least gives some positive effect. However, as in the case of other similar products, independent experts agree that the degree of usefulness is overestimated by the manufacturer.

Watch this video on YouTube

One comment

Fedor

I filled the 2nd syringe and did not notice any changes. In the morning I'll listen to how the vanos work when starting up. I bought it on ozone.