Gear problem

Shifting and shifting should be smooth, precise, and without undue pressure on the shift lever. If this is not the case, you must quickly find the cause and eliminate it.

Shifting and shifting should be smooth, precise, and without undue pressure on the shift lever. If this is not the case, you must quickly find the cause and eliminate it.

Rough shifting, especially reverse gear, can be considered normal when the engine is cold. While  Resistance to shifting into gear even after the engine has warmed up can be caused by various reasons. One of them is the use of unsuitable, too thick oil, contrary to the manufacturer's recommendations.

Resistance to shifting into gear even after the engine has warmed up can be caused by various reasons. One of them is the use of unsuitable, too thick oil, contrary to the manufacturer's recommendations.

If a grinding noise is heard when shifting gears (despite proper clutch operation), this is a typical sign of synchronizer wear. In addition, the transmission may be switched off, i.e. loss of gear while driving. The driver himself is often to blame for the premature wear of the synchronizers, who allows the clutch to be partially disengaged when shifting gears, reduces gears at too high a speed, changes gears abruptly, preventing the synchronization process from proceeding normally. Synchronizers also don't like to ride in high gears at too low a speed.

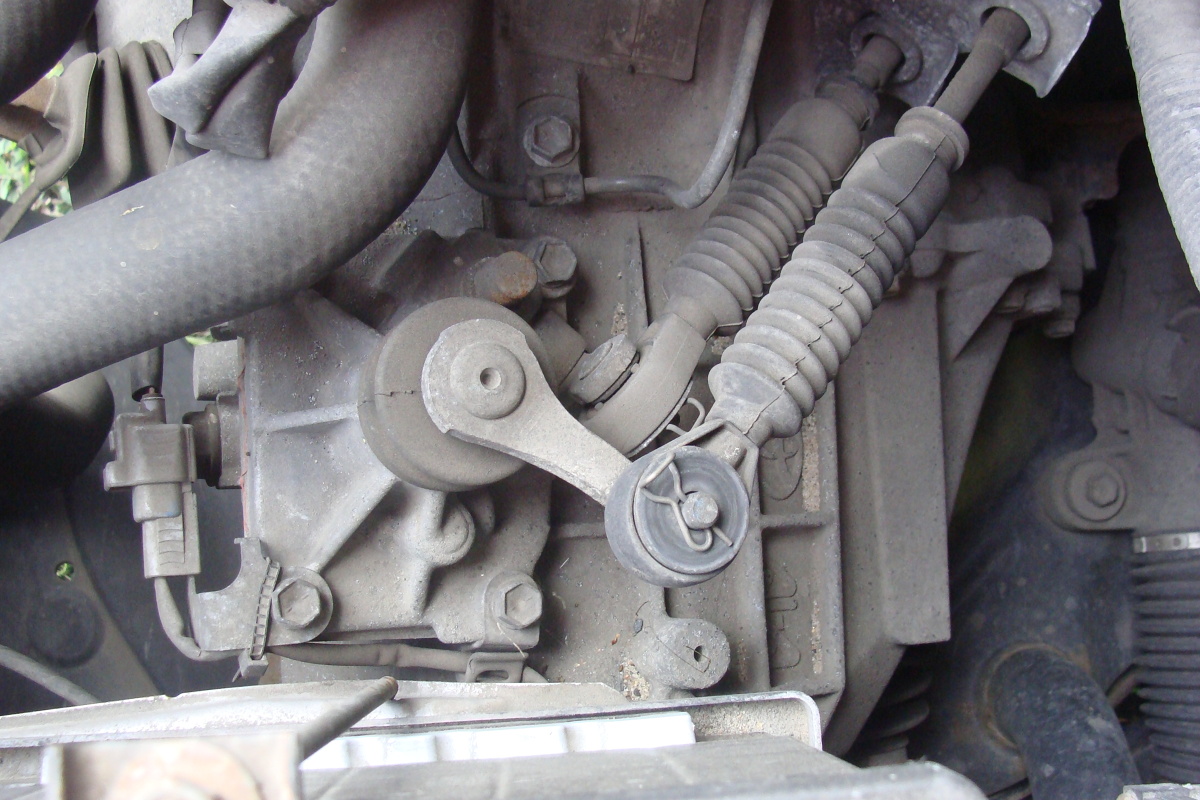

A source of difficulty when shifting gears and the cause of premature wear of the synchronizers can also be the flywheel bearing in which the clutch shaft is installed. Seized bearing causes deformation of the clutch shaft journal. The practice of workshops also fixes cases of synchronizer wear caused by damage to the crankshaft vibration damper.

In addition to worn synchromesh, deficiencies in the internal shift mechanism can also be the cause of difficult shifting. In vehicles where the gearshift lever is located at a distance from the internal gearshift mechanism, i.e. the gearbox itself, the gear selection is carried out using an appropriate system of levers or cables. Any malfunctions in this system in the form of excessive play or deformation of the components can also make shifting difficult.