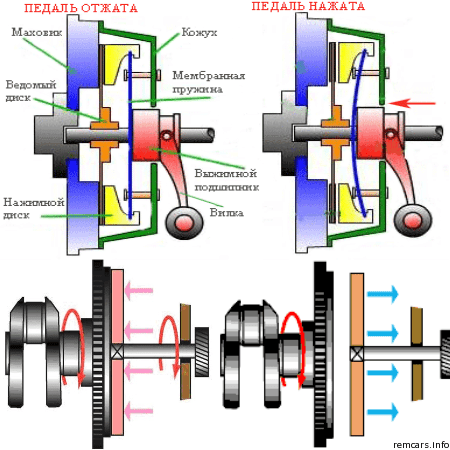

clutch slip

In a properly functioning clutch, this phenomenon occurs most often at the moment of starting off, and then completely disappears.

In a properly functioning clutch, this phenomenon occurs most often at the moment of starting off, and then completely disappears.

Unnecessary and harmful constant slippage of the clutch is caused by many other reasons.  mechanical and thermal damage, as well as incorrectly performed repairs, as well as improper operation. These are the most common causes of clutch slip.

mechanical and thermal damage, as well as incorrectly performed repairs, as well as improper operation. These are the most common causes of clutch slip.

- overheating of the pressure plate due to thermal overload, a broken diaphragm spring, as well as used parts that are not suitable for repair. Local overheating of the clamp is also the result of damage to the impression mechanism or too long and frequent clogging of the so-called coupling half.

- Excessively worn clutch disc friction linings as a result of natural wear, but exceeding the allowable thickness. Excessive lining wear is also caused by, among other things, a damaged extrusion unit and inadequate bonding.

- Oily clutch disc friction linings are the result of a damaged crankshaft seal or excessive lubrication of the clutch shaft. In extreme cases, getting oil or grease on the pads will cause them to burn (char).

- belleville spring sheets are damaged, most often as a result of a lack of play between them and the release bearing, too much resistance of the release bearing, or its jamming.

- deformation of the compression ring housing or diaphragm spring due to incorrect assembly.

- wear of the guide bush due to insufficient or complete lack of lubrication, resistance of the release bearing, as well as improper use of parts in a previous repair.

- too high tendon resistance due to wear or improper assembly.

- improper fit of the disc pads to the flywheel due to deformation or damage to the surface of the flywheel.