Checking diesel injectors

Content

The nozzles of a diesel engine, as well as an injection engine, are periodically contaminated. Therefore, many owners of cars with diesel ICE are wondering - how to check diesel injectors? usually, in case of clogging, fuel is not supplied to the cylinders in a timely manner, and increased fuel consumption occurs, as well as overheating and destruction of the piston. In addition, burnout of the valves is possible, and failure of the particulate filter.

Diesel engine injectors

Checking diesel injectors at home

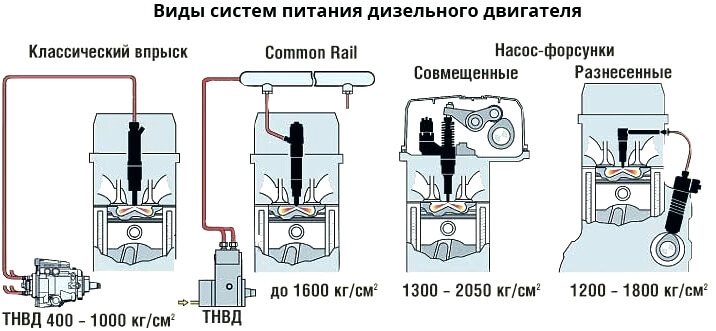

In modern diesel ICEs, one of two known fuel systems can be used everywhere. Common Rail (with a common ramp) and a pump-injector (where on any cylinder its own nozzle is supplied separately).

Both of them are able to provide high environmental friendliness and efficiency of internal combustion engines. Since these diesel systems function and are arranged in a similar way, but Common Rail is more progressive in terms of efficiency and noise, although it loses in power, it has become more and more often used on passenger cars, then we will talk about it further. And we’ll tell you about the operation, breakdowns and checking of the injector pump separately, because this is no less interesting topic, especially for owners of VAG group cars, since software diagnostics are not difficult to perform there.

The simplest method for calculating a clogged nozzle of such a system can be carried out according to the following algorithm:

Common Rail Injector

- at idle, bring the engine speed to the level where problems in the operation of the internal combustion engine are most clearly audible;

- each of the nozzles is turned off by loosening the union nut at the attachment point of the high pressure line;

- when you turn off the normal working injector, the operation of the internal combustion engine changes, if the injector is problematic, then the internal combustion engine will continue to work in the same mode further.

In addition, you can check the nozzles with your own hands on a diesel engine by probing the fuel line for shocks. They will be the result of the fact that the high-pressure fuel pump is trying to pump fuel under pressure, however, due to the clogging of the nozzle, it becomes difficult to skip it. A problem fitting can also be identified by an elevated operating temperature.

Checking diesel injectors for overflow (drain into the return line)

Checking the volume of discharge to the return

As diesel injectors wear out over time, there is a problem associated with the fact that the fuel from them gets back into the system, due to which the pump cannot deliver the desired working pressure. The consequence of this may be problems with the start and operation of a diesel engine.

Before the test, you will need to buy a 20 ml medical syringe and a drip system (you will need a 45 cm long tube to connect the syringe). in order to find an injector that throws more fuel into the return line than it should, you need to use the following algorithm of actions:

- remove the plunger from the syringe;

- on a running internal combustion engine, using the system, connect the syringe to the “return” of the nozzle (insert the tube into the neck of the syringe);

- hold the syringe for two minutes in order for fuel to be drawn into it (provided that it will be drawn);

- repeat the procedure one by one for all injectors or build a system for all at once.

Based on the information about the amount of fuel in the syringe, the following conclusions can be drawn:

Checking the overflow to the return

- if the syringe is empty, then the nozzle is fully functional;

- the amount of fuel in a syringe with a volume of 2 to 4 ml is also within the normal range;

- if the volume of fuel in the syringe exceeds 10 ... 15 ml, this means that the nozzle is partially or completely out of order, and it needs to be replaced / repaired (if it pours 20 ml, then it is useless to repair, since this indicates wear of the nozzle valve seat ), since it does not hold fuel pressure.

However, such a simple check without a hydro stand and a test plan does not give a complete picture. After all, in reality, during the operation of an internal combustion engine, the amount of fuel discharged depends on many factors, it can be clogged and needs to be cleaned or it hangs and needs to be repaired or replaced. Therefore, this method of checking diesel injectors at home only allows you to judge only about their throughput. Ideally, the amount of fuel they pass through should be the same and be up to 4 ml in 2 minutes.

In order for the injectors to operate as long as possible, refuel with high-quality diesel fuel. After all, it directly depends on the operation of the entire system. In addition, install original fuel filters and do not forget to change them in time.

Checking injectors using special devices

A more serious test of diesel engine injectors is carried out using a device called maximeter. This name means a special exemplary nozzle with a spring and a scale. With their help, the pressure of the start of injection of diesel fuel is set.

Another verification method is to use control model working nozzle, with which the devices used in the internal combustion engine are compared. All diagnostics are performed with the engine running. The algorithm of actions is as follows:

Maximeter

- perform the dismantling of the nozzle and the fuel line from the internal combustion engine;

- a tee is connected to the free union of the high pressure fuel pump;

- loosen the union nuts on other injection pump fittings (this will allow fuel to flow to only one nozzle);

- the control and test nozzles are connected to the tee;

- activates the decompression mechanism;

- rotate the crankshaft.

Ideally, the control and test injectors should show the same results in terms of the simultaneous start of fuel injection. If there are deviations, then it is necessary to adjust the nozzle.

The control sample method usually takes longer than the maximometer method. However, it is more accurate and reliable. you can also check the operation of the internal combustion engine and diesel engine injectors and injection pump on a special adjustment stand. However, they are only available at specialized service stations.

Cleaning diesel injectors

Cleaning diesel injectors

you can clean the nozzles of a diesel engine yourself. Work must be carried out in a clean and well-lit environment. To do this, the nozzles are removed and washed either in kerosene or in diesel fuel without impurities. Blow out the nozzle with compressed air before reassembly.

it is also important to check the quality of fuel atomization, that is, the shape of the “torch” of the nozzle. There are special techniques for this. First of all, you need a test bench. There they connect the nozzle, supply fuel to it and look at the shape and strength of the jet. Often, a blank sheet of paper is used for testing, which is placed under it. Traces of fuel hit, the shape of the torch and other parameters will be clearly visible on the sheet. Based on this information, the necessary adjustments can be made in the future. A thin steel wire is sometimes used to clean the nozzle. Its diameter must be at least 0,1 mm smaller than the diameter of the nozzle itself.

Possible breakdowns of diesel injectors

The most common cause of failure is a violation of the tightness of the needle in the nozzle guide sleeve. If its value is reduced, then a large amount of fuel flows through the new gap. namely, for a new injector, a leakage of no more than 4% of the working fuel that enters the cylinder is allowed. In general, the amount of fuel from the injectors should be the same. You can detect a fuel leak at the injector as follows:

- find information about what pressure should be when opening the needle in the nozzle (it will be different for each internal combustion engine);

- remove the nozzle and install it on the test bench;

- create a knowingly high pressure at the nozzle;

- using a stopwatch, measure the time after which the pressure will drop by 50 kgf / cm2 (50 atmospheres) from the recommended one.

Checking the injector at the stand

This time is also spelled out in the technical documentation for the internal combustion engine. Usually for new nozzles it is 15 seconds or more. If the nozzle is worn, then this time can be reduced to 5 seconds. If the time is less than 5 seconds, then the injector is already inoperative. You can read additional information on how to repair diesel injectors (replace nozzles) in the supplementary material.

If the valve seat of the injector is worn out (it does not hold the required pressure and excessive draining occurs), the repair is useless, it will cost more than half the cost of a new one (which is about 10 thousand rubles).

Sometimes a diesel injector can leak small or large amounts of fuel. And if in the second case only repair and complete replacement of the nozzle is necessary, then in the first case you can do it on your own. namely, you need to grind the needle to the saddle. After all, the basic cause of leakage is a violation of the seal at the end of the needle (another name is a sealing cone).

To remove leakage from a diesel nozzle, a thin GOI grinding paste is often used, which is diluted with kerosene. During lapping, care must be taken to ensure that the paste does not get into the gap between the needle and the sleeve. At the end of the work, all elements are washed in kerosene or diesel fuel without impurities. After that, you need to blow them with compressed air from the compressor. After assembly, check again for leaks.

Conclusions

Partially defective injectors are not critical, but very unpleasant breakdown. After all, their incorrect operation leads to a significant load on other components of the power unit. In general, the machine can be operated with clogged or misconfigured nozzles, but it is desirable to make repairs as soon as possible. This will keep the internal combustion engine of the car in working order, which will also save you from large cash costs. So, when the first symptoms of unstable operation of the injectors on your diesel car appear, we recommend that you check the performance of the injector at least in an elementary way, which, as you can see, it is quite possible for everyone to produce at home.