Audi 80 checkpoint work

The transmission of the car during operation experiences significant loads, and the subsequent operation of the car directly depends on its condition. Do-it-yourself minor repairs of the Audi 80 v3 gearbox for an owner who understands cars will not be difficult, and the unpretentiousness and durability of the transmission make it possible not to remember it for quite some time. But sometimes there are several types of malfunctions, and the comfort during the trip and the safety of the driver and passengers depend on the speed of their elimination.

Speedometer repair

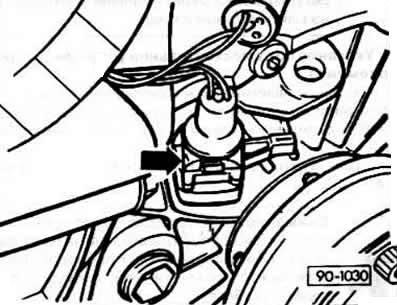

The reason for the malfunction of the speedometer of the car and the mechanics may lie in poor contact in the area of \uXNUMXb\uXNUMXbthe dashboard or in the speed sensor. In the presence of one hundred percent confidence in the serviceability of the car, all work to restore performance is carried out under the hood. The speed sensor is located on the left side at the top of the gearbox and is easy to get to. Removing it is easy enough - you need to press the bracket with a screwdriver and turn it clockwise. There are no bolts or nuts, which, of course, is a plus of this design.

Often the cause of failure is a large amount of dirt and oxidized contacts that prevent the signal from passing through normally.

After disassembling and thoroughly cleaning it from dirt and removing the plate from the contacts, you can install the sensor in its original place and continue checking its performance.

The speedometer needle after a simple repair should move smoothly and without jerks.

Reverse sensor repair

The cost of a new part is often the reason that the driver ignores this malfunction, but not in all cases the reverse sensor dies irrevocably. Usually its repair consists in a thorough cleaning of the contacts and terminals, which takes a lot of time. The reverse button on the audi 80 v3 mechanics is installed on the right side under the battery. To access it, remove the battery and the rubber gasket on them. The hole at the bottom provides the car owner with access for repairs.

The reverse sensor is attached to the gearbox with a 13 bolt holding its plate and two more, which need an asterisk to unscrew.

After removal and disassembly, the mechanics speed sensor is thoroughly washed and all contacts are cleaned. Often the spring that pushes the barrel "gets tired" and needs to be stretched a little for normal operation. After the cleaning process, you can install and check the performance of the repaired audi 80 v3 and b4 sensor.

Changing pillows

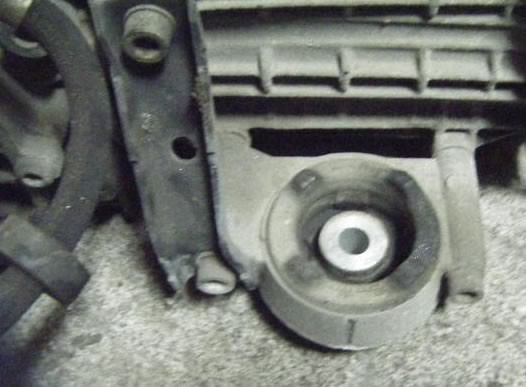

Strong vibrations during the operation of the Audi b3 and b4 engine while driving can lead to failure of the pillows. To check, turn on reverse gear and accelerate the car; in this case, the vibrations of the engine and mechanics will be as strong as possible, which excludes all other possible malfunctions. Replacing the box cushion with an Audi 80 b3 is not too difficult in itself, especially if you find out the sequence of actions before starting the repair.

- Using a jack, the gearbox is slightly raised.

- We unscrew the central bolt of the pillow.

- The subframe bolt is slightly loosened, which will allow the pillow support to move freely.

- The support is retracted and 2 bolts holding the pillow are unscrewed.

- Then you need to remove the pillow and replace it with a new one.

- Reassemble in the reverse order.

Repairing a pillow with improvised means takes even an inexperienced driver no more than 30 minutes. Automatic transmission cushions and audi b3 mechanics are exactly the same, and the method of removing and replacing them does not depend on the type of box and year of manufacture.

Replacing oil seals on the gearbox

Over time, the 80 Audi 2 B1985 will need to replace the input shaft seals, gearboxes and gear selector.

When choosing a replacement, you need to pay attention to some details:

- the input shaft oil seal has grooves in the form of a thread, which is associated with its one-way rotation;

- stuffing box grooves of the nodes are made in the form of a wave, which is associated with a different direction of its movement;

- the grooves in the rod gland are straight, because the movements in this area are minimal.

The primary oil seal in the gearbox changes quite simply - its cover is unscrewed and a new one is pressed in place of the old one. When installing the mechanical cover in place, it is recommended to lubricate the joint with sealant.

The stem seal in mechanics is removed a little more difficult, despite its availability. You can remove it with a screwdriver, hammer along the contour, and then pull out the gland. The new one is simply carefully placed on the stem of the mechanics and that's it.

Basically, the replacement of transmission oil seals on mechanics and automatic machines is no different and is also carried out with the help of simple manipulations.

Timely maintenance of the gearbox will significantly increase its service life and reduce the cost of the car owner for its repair; we must not forget this. Replacing the manual transmission audi 80 v2 1985 is associated with some difficulties: it is necessary to observe the established gear ratio of the box; otherwise, normal operation is not guaranteed.