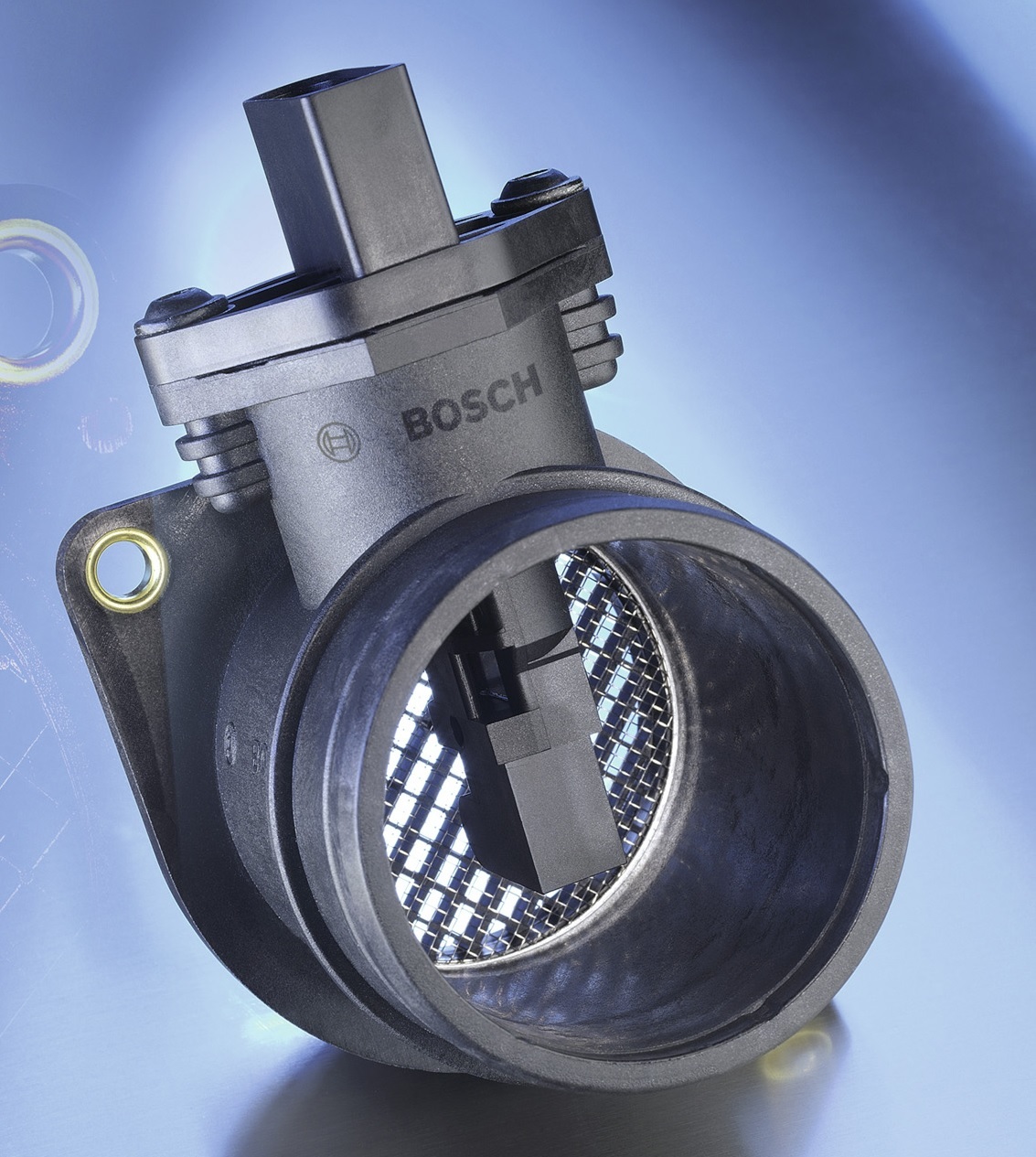

Air mass meter

Its signal is used to determine the engine load, which, along with the crankshaft speed, is the main parameter for calculating the base fuel dose.

Its signal is used to determine the engine load, which, along with the crankshaft speed, is the main parameter for calculating the base fuel dose.

Electronically controlled multi-point systems initially used gasoline indirect injection.  damper air flow meters for measuring the volume flow taken in by the engine. Later they were replaced by hot-wire meters. Their work is based on the fact that the air drawn in by the engine flows around an electrically heated element. This role was played for the first time by platinum wire. The control system supplies the wire with electricity so that its temperature is always higher than the intake air temperature by a constant value. Maintaining a constant temperature difference with an increase in the amount of intake air, which cools the wire more strongly, requires an increase in the amount of current flowing through the wire, and vice versa. The heating current value is the basis for calculating the motor load. The disadvantage of this solution was a rather high sensitivity to shock and mechanical damage. Today, a laminated heating element is used in hot-wire flowmeters. It is shock and electromagnetic field resistant.

damper air flow meters for measuring the volume flow taken in by the engine. Later they were replaced by hot-wire meters. Their work is based on the fact that the air drawn in by the engine flows around an electrically heated element. This role was played for the first time by platinum wire. The control system supplies the wire with electricity so that its temperature is always higher than the intake air temperature by a constant value. Maintaining a constant temperature difference with an increase in the amount of intake air, which cools the wire more strongly, requires an increase in the amount of current flowing through the wire, and vice versa. The heating current value is the basis for calculating the motor load. The disadvantage of this solution was a rather high sensitivity to shock and mechanical damage. Today, a laminated heating element is used in hot-wire flowmeters. It is shock and electromagnetic field resistant.

Since the signal from the air mass meter is extremely important for the correct operation of the engine, its control takes into account the self-diagnosis of injection systems. For example, Motronic constantly compares the injection timing based on the mass of intake air with that calculated based on the engine speed and throttle angle. If these times are clearly different, then it is stored in the diagnostic memory of the controller, and further driving serves to check which sensor was damaged. After the controller recognizes a faulty sensor, the corresponding error code appears in the controller's memory.

Damage to the mass air flow sensor can manifest itself, including a decrease in engine power, uneven operation and excessive fuel consumption.