Distribution of 4-stroke engines

Content

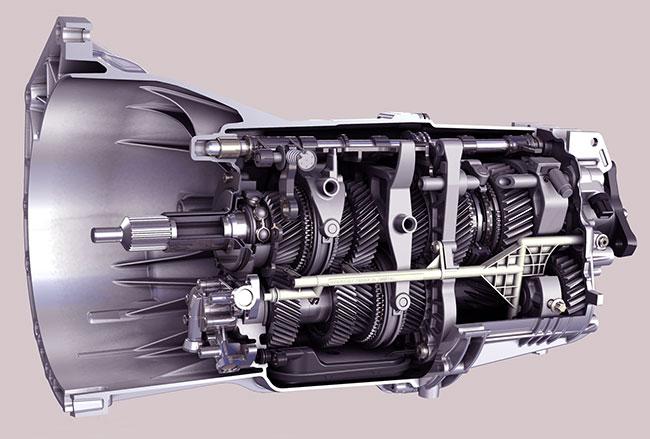

camshaft for valve control

Composed of valves and one or more camshafts, the distribution is the heart of a 4-stroke engine. It is on it that the performance of the motorcycle is based.

To control the synchronized opening and closing of the valves, a camshaft is used, that is, the rotating axle on which the eccentrics were installed, which will push the valves so that they sink and open when the time comes. The valve is not always controlled directly by the camshaft (fuses). Indeed, it all depends on their relative position. On the first 4-stroke engines, valves were implanted from the side, head up, on the side of the cylinder. Then they were operated directly by the camshaft, which itself was located near the crankshaft axis.

Gas powered, presented in Milan in 2007, a prototype motorcycle equipped with a side valve test engine. An extremely simple and compact solution reminiscent of a past that has little or no motorcycle presence since Harley Flathead came to a standstill in 1951.

From side flaps to top flaps ...

The system, which is very simple, had the disadvantage of a "warped" combustion chamber, as the valves arrived close to the cylinder. This was affected by engine performance and the lead valves were quickly installed. The term is from the translation, since the cylinder head is called "head" in many foreign languages: for example, English, German, Italian. In the specifications, and sometimes directly on the crankcases, you can see the English abbreviation "OHV", which means "Header Valves", valves in the head. The acronym is now obsolete, which is only found on lawn mowers as a point of sale ...

Can do better ...

Therefore, to make the combustion chamber more compact, the valves were tilted to return them to the vertical of the cylinder and piston. Then we talked about "fuck" engines. Incineration has increased efficiency. However, since the camshaft remained in the same place, long rods had to be implanted to operate the valves, and then rockers (scalmers) had to be implanted to reverse the upward movement of the cams with a push that lowers the valves.

In the relatively distant past, this type of spread was still used mainly on English (60s-70s) and Italian (Moto Guzzi) motorcycles.

OHV then OHC

The single ACT (head camshaft) solution is still well suited for single cylinders that don't run at too high speeds, such as the 650 XR here.

However, the weight and number of moving parts have doubled the damage to the search for power. Indeed, the faster the valves open and close, the longer they can stay open, which contributes to the filling of the engine, hence its torque and power. Likewise, the faster the engine runs, the more “explosions” it provides and, therefore, the more powerful it is. But mass, being the enemy of acceleration, these heavy and complex systems were unlikely to be effective back and forth. In fact, we had the idea to raise the camshaft into the cylinder head (in the head like this ...) to eliminate the long and heavy rocker stems. In English we are talking about "Inverted camshaft", which is shortly spelled by OHC. The technology is finally still up to date as Honda (and Aprilia) still use it consistently, with some adaptations called "Unicam".

Unik

The Unicam Honda only has one ACT that directly controls the intake valves, while the smaller, therefore lighter exhaust valves use slopes.

Next week we will take a closer look at the double ACT ...

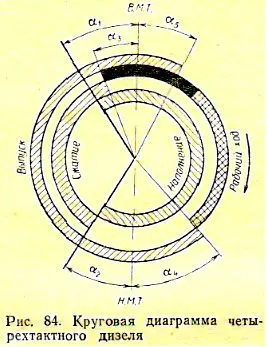

Box: What is Valve Panic?

This phenomenon is comparable to what happens when an army walks across a bridge. The cadence excites the bridge structure at a speed corresponding to its own resonant mode. This leads to a very wide movement of the bridge and, ultimately, its destruction. It's the same with distribution. When the excitation frequency of the camshaft reaches the frequency of the valve opening and closing mechanism, the system finds a response. This then leads to uncontrolled valve movements that no longer follow the camshaft profile. In fact, they no longer close when the piston rises ... and bing, it hits, causing the engine to collapse. The lower the mass of the distribution, the higher its resonant frequency and thus moves away from the engine speed (i.e. the speed at which it can rotate). CQFD.