Regeneration and repair of diesel injectors. The best injection systems

Content

One of the main conditions for the correct operation of a diesel engine is an efficient injection system. Together with an experienced mechanic, we describe the least and most unreliable injection systems.

One of the main conditions for the correct operation of a diesel engine is an efficient injection system. Together with an experienced mechanic, we describe the least and most unreliable injection systems.

The engine is more energy efficient the higher the fuel injection pressure. In diesel engines, diesel fuel is injected into the combustion chamber at very high pressure. Thus, the injection system, i.e. the pump and injectors, is a key component of these engines.

Various fuel injection systems on diesel engines

Injection systems in diesel units have undergone a technological revolution over the past twenty years. Thanks to him, popular abscesses are no longer perceived as an obstacle to smoking. They have become economical and fast.

Today, direct fuel injection is standard on diesel engines. The most common system is Common Rail. The system was developed by Fiat in the early 90s, but the patent was sold to Bosch due to high production costs. But the first car with this system was in 1997 Alfa Romeo 156 1.9 JTD.

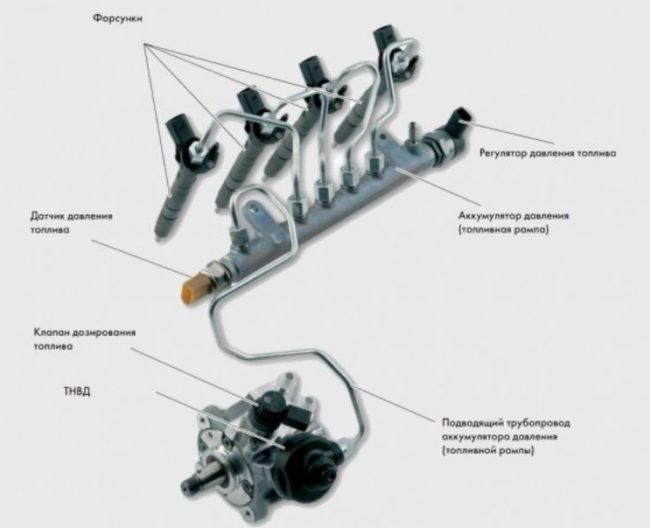

In a common rail system, fuel is collected in a common pipe and then distributed under high pressure to the injectors. The valves in the injectors open depending on the engine speed. This ensures an optimal composition of the mixture in the cylinders and reduces fuel consumption. Just before the actual fuel injection, the so-called pre-injection to pre-heat the combustion chamber. Thus, faster ignition of the fuel and quieter operation of the power unit were achieved.

There are two types of Common Rail systems: with electromagnetic injectors (so-called Common Rail 2003th generation) and with piezoelectric injectors (so-called XNUMXth generation). The latter are more modern, have fewer moving parts and lighter weight. They also have shorter shift times and allow for more accurate fuel metering. Since XNUMX, most manufacturers are gradually switching to them. Brands used for solenoid injectors include Fiat, Hyundai/KIA, Opel, Renault and Toyota. Piezoelectric injectors are used in particular in new engines. Mercedes, PSA concern (owner of Citroen and Peugeot), VW and BMW.

See also Glow plugs in diesel engines - work, replacement, prices. Guide

Another solution for direct fuel injection in diesel engines are unit injectors. However, it is no longer used in new cars. The pump injectors have given way to the Common Rail system, which is more efficient and quieter. Volkswagen, which promoted this solution, also does not use them.

A few years ago, Volkswagen and related brands (Audi, SEAT, Skoda) used unit injectors. This is a unit injector injection system (UIS). The main components are mono-injectors located directly above the cylinders. Their task is to create high pressure (over 2000 bar) and injection of diesel fuel.

ADVERTISING

Reliability of injection systems

Mechanics emphasize that along with the development of injection systems, their reliability has decreased.

- The least emergency diesel injection systems are those that were released several decades or even several years ago, in which the main element was the high-pressure fuel pump distributor - says Marcin Geisler from Auto-Diesel-Service from Kobylnica near Słupsk.

For example, the popular Mercedes W123 barrels had indirect injection. There were few moving parts, and the mechanism worked even on a small amount of fuel. The downside, however, was poor acceleration, noisy engine operation and high diesel fuel consumption compared to today's powertrains.

New designs - with direct injection - are devoid of these shortcomings, but are much more sensitive to fuel quality. This is mainly why systems with electromagnetic injectors are less reliable than systems with piezoelectric ones.

“They're just more resistant to bad fuel. Piezoelectrics quickly fail when in contact with contaminated diesel fuel. – explains Geisler – The quality of diesel fuel is one of the main factors affecting the operation of the entire system. Contaminated fuel that does not meet standards is the cause of trouble.

See also Beware of baptized fuel! Fraudsters bypass checks at stations

There are also systems with electromagnetic nozzles that break more often than others. This is the case, for example, in the Ford Mondeo III with 2.0 and 115 hp 130 TDCi engines. and Ford Focus I 1.8 TDCi. Both systems used Delphi branded systems.

- The cause of the malfunction of the injection pump. After disassembling it, you can notice metal filings, which, of course, damage the nozzles, the mechanic explains. - It is difficult to say whether this affected the quality of the fuel or whether the production technology of these pumps was defective.

Similar problems are typical for Renault Megane II with a 1.5 dCi engine. The Delphi pump is also working here, and in the fuel system we also find metal filings.

Notoriety also accompanies Opel diesels, in which the VP44 pump works. These engines drive, among others, the Opel Vectra III 2.0 DTI, Zafira I 2.0 DTI or Astra II 2.0 DTI. As Gisler says, at a run of about 200 thousand km, the pump seizes and requires regeneration.

On the other hand, HDi engines, produced by the French concern PSA and used in Citroen, Peugeot, and since 2007 in Ford cars, have problems with access to original spare parts, i.е. Siemens injectors.

“A defective nozzle can be replaced with a used one, but I do not recommend this solution, although it is cheaper,” the mechanic notes.

ADVERTISING

Repair prices

The cost of repairing the injection system depends on the type of injectors. The repair of these electromagnetic devices costs about PLN 500 each, including labor, and consists in the replacement of individual elements of the injector.

– This is the price when using original spare parts. In the case of precision devices such as an injector, it is better not to use substitutes, emphasizes Marcin Geisler.

Therefore, in the case of Denso systems used in Toyota engines, it is necessary to replace the entire injector, as there are no original components on the market.

Piezoelectric nozzles can only be replaced as a whole. The cost is PLN 1500 per piece, including labor.

– Piezoelectric injectors are relatively new components and their manufacturers are still protecting their patents. But this was the case with electromagnetic nozzles in the past, so after some time the prices for repairing piezoelectrics will probably fall, our source believes.

See also Gasoline, Diesel or LPG? We calculated how much it costs to drive

Cleaning the injection system, i.e. prevention

In order to avoid problems with the injection system, it must be cleaned regularly with special preparations.

“It’s worth doing this once a year, for example, when changing engine oil and filters,” the mechanic advises.

The cost of this service is approximately PLN 350.

Wojciech Frölichowski