Starter regeneration step by step - how to do it?

Content

- Starter - is it worth regenerating this element?

- Starter regeneration - disassembly and cleaning?

- Starter regeneration - preliminary diagnostics

- Starter regeneration - when is it necessary?

- Starter solenoid repair - is it possible?

- Starter regeneration - workshop price

- The cost of regenerating a starter and buying a regenerated one

- Starter regeneration step by step - can I do it myself?

An internal combustion engine must be brought to its original stroke in order to start working. Therefore, it comes with an electric motor. Unfortunately, its elements wear out over time. However, starter regeneration is possible and gives satisfactory results. How is it done? How much does it cost to replace a starter and what is the cost to regenerate a starter? Check out what works best. We advise and dispel doubts!

Starter - is it worth regenerating this element?

Definitely yes, but it depends on several factors. First of all, it is the quality of the work done in the workshop. There are "professionals" who only change the brushes and clean the starter. Usually the effect is satisfactory for the next few days. Shortly thereafter, the starter needs to be repaired again, especially when other parts are badly worn. Therefore, it is very important to choose a good workshop. The second factor is the quality of the selected repair elements. Their strength level determines how long the regenerated element will last.

Starter regeneration - disassembly and cleaning?

What does starter regeneration look like? At the very beginning, the mechanic disassembles the element. Remember that simply removing the starter motor can be very tiring because it is located next to the crankshaft flywheel. After removing this part and putting it on the table, the electrician gets to work. First, the element is cleared so that it can be worked with without problems. Of course, before complete disassembly into its component parts, this cleaning is preliminary. Next, the specialist proceeds to sandblasting and, possibly, painting the body.

Starter regeneration - preliminary diagnostics

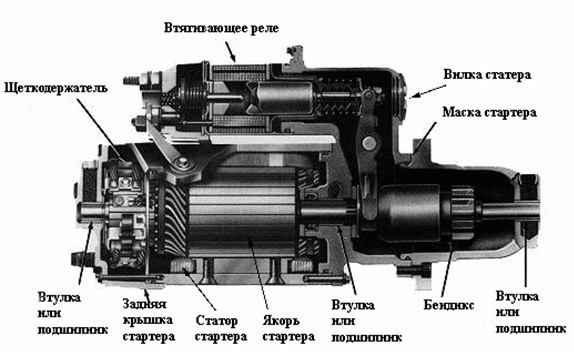

It is usually worth watching the operation of the machine with the gear and its slipping when voltage is applied at the very beginning. This simple procedure enables an initial assessment of the situation. If the teeth on the machine itself are damaged, this could also indicate a mechanical problem with the flywheel. Regeneration of the starter at the following stages consists in the complete disassembly of all elements, which include:

- auto;

- carbon brushes;

- rotor;

- stand;

- bendix (coupling unit);

- electromagnetic switch.

Starter regeneration - when is it necessary?

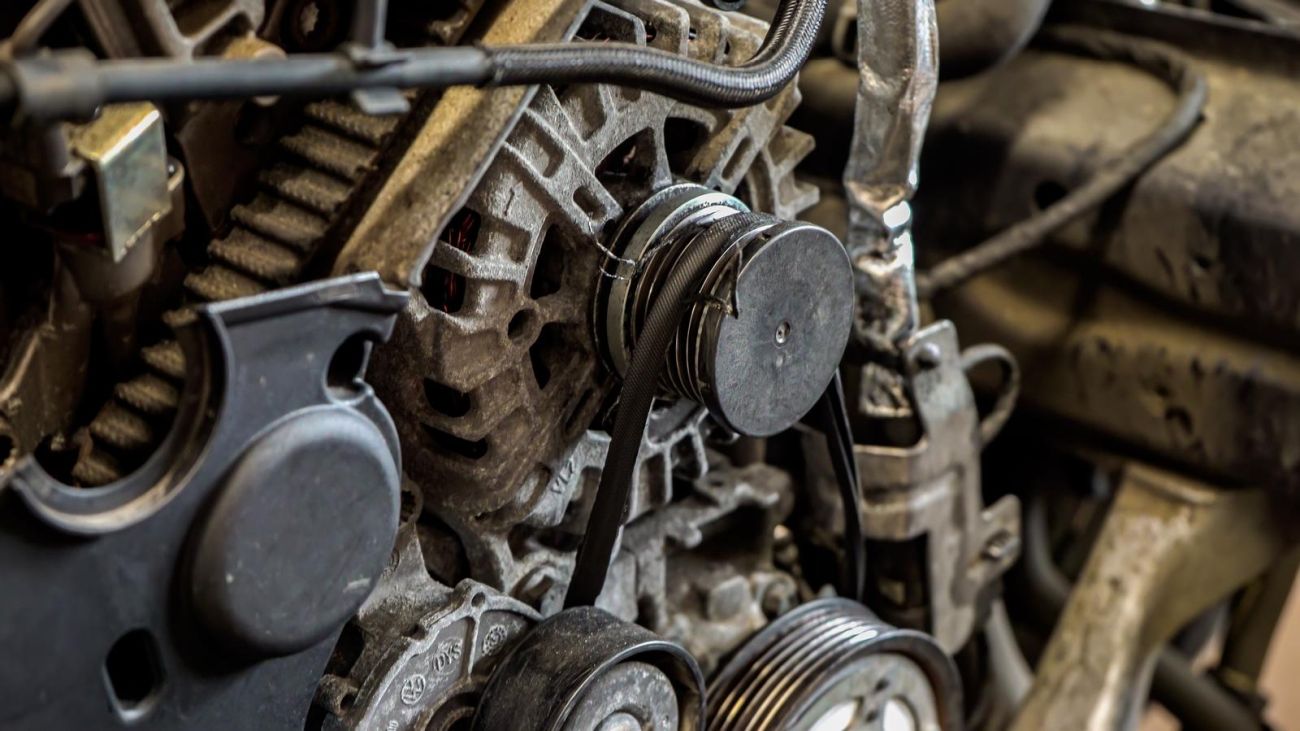

An electric motor that starts a combustion unit is much heavier than itself, of course, is subject to operation. However, carbon brushes are most often damaged. Their size decreases as the starter wears out and they simply need to be replaced. The next element is the rotor bearings. They can be damaged by constant rotation. Abrasive carbon brushes form a coating which, in combination with the lubricant present in the bearings, can cause them to wear faster.

Bendix and contacts, i.e. other parts subject to damage

Another element that includes starter regeneration is the bendix. This mechanism is threaded to connect the drive sprocket to the flywheel. If the thread on the bendix is damaged, the pinion gear cannot smoothly fit on the teeth of the flywheel. The problem may also lie in the contacts that do not pass electric current to the rotor brushes.

Starter solenoid repair - is it possible?

In older components (like the Fiat 126p) the electromagnet could be removed. In case of damage, it was enough to unsolder the wires and climb inside to clean the contact elements. In currently produced cars, the electromagnet is non-separable and can only be replaced with a new one.

Starter regeneration - workshop price

How much does a starter rebuild cost? This expense usually ranges from 100-40 euros. The cost of rebuilding a starter depends on the model of the component as well as the amount of work that needs to be done. The number of parts that need to be replaced also greatly affects the price. The amount above may seem high, but compared to what it costs starter, slightly. Often you have to pay at least 50 euros for a new copy of good quality. Of course, we are talking about popular power units, such as the indestructible 1.9 TDI from VAG.

The cost of regenerating a starter and buying a regenerated one

You already know how much a starter repair service costs, but then why not buy a cheaper replacement? On the Internet you will find offers to buy remanufactured components, as well as parts that have been used and only tested on the table. It's basically your choice which solution you choose. Sometimes a rebuild will cost even more than a used starter in good condition. However, you're not sure how long it will last, and starter rebuilds usually come with a one-year warranty.

Starter regeneration step by step - can I do it myself?

You can do the replacement in your home garage if you have a basic understanding of how the component works. You will also need a tool kit and an electric meter. Removing the element from the engine bay can be easy or a little tricky depending on the vehicle. However, the replacement of carbon brushes on the brush holder, as well as quality control of elements (for example, a collector) or a thorough cleaning of the interior are within the power of most needlework lovers.

Regeneration of the starter is associated with costs, but sometimes it is worth doing. When you have repair skills, you can try to do it yourself. However, remember that disassembling the starter and then carrying it to the electromechanical workshop is not welcome. Mechanics usually don't like fixing things they've tampered with before. Therefore, if you are not confident in your abilities, the starter should be regenerated at a specialized facility.