Turbocharger regeneration - why is it better to entrust turbine repair to specialists?

Content

- Before regeneration of the turbocharger is necessary, i.e. a few words about the turbocharger

- Turbocharger and regeneration - what can go wrong in it?

- Small turbochargers and regeneration - why are they especially stressed?

- What else turbines suffer from - repair of other engine components

- Find out what turbine regeneration is

- Turbine and regeneration - what happens to it after flushing?

- How much does it cost to restore a turbine in a car?

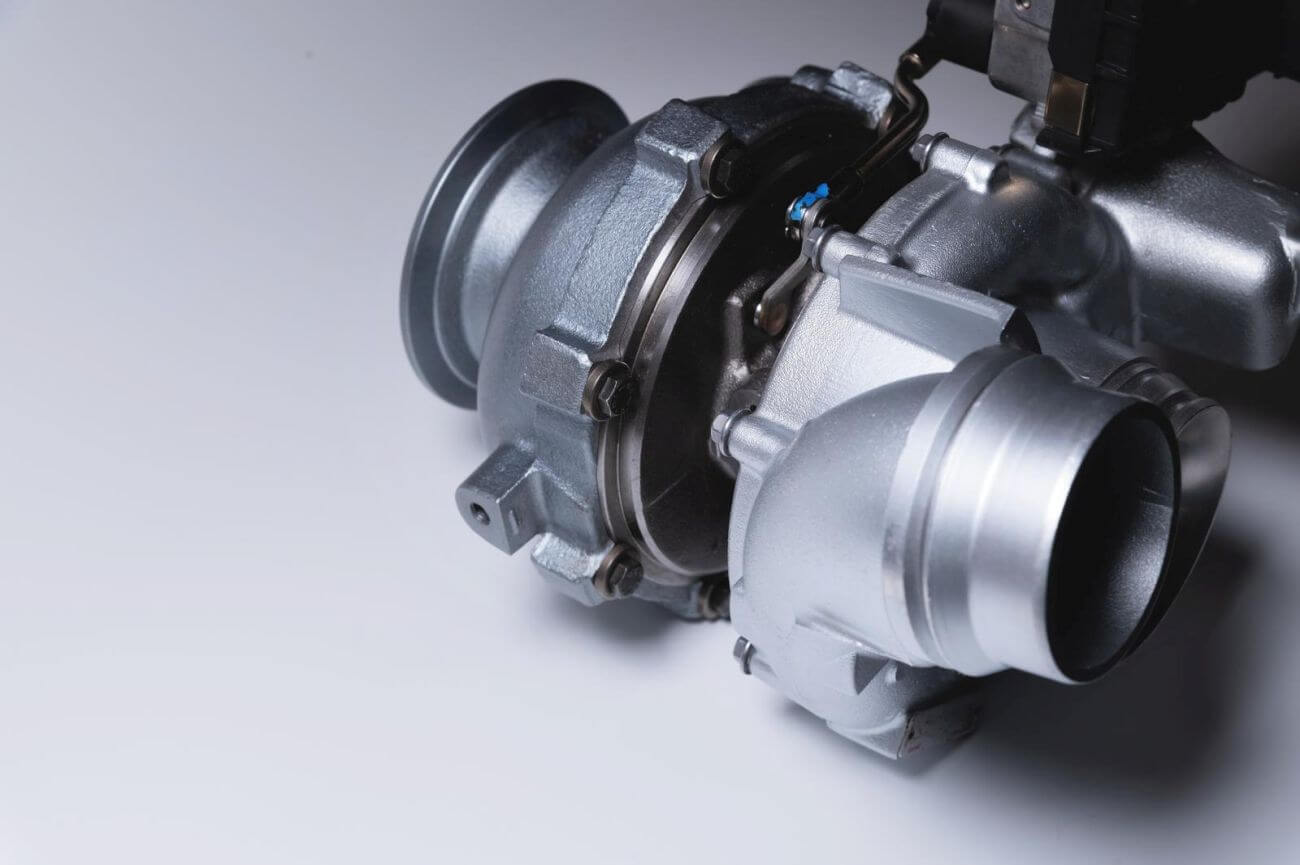

In the past, turbochargers were either fitted to sports cars, trucks or diesels. Today, almost every car is equipped with a turbocharger. This results in a higher output per liter of capacity, reduced fuel consumption and compliance with emission standards. The turbo also provides flexibility from lower revs, so it's useful to get the right amount of torque when driving the car in town, for example. How does such a system work?

Before regeneration of the turbocharger is necessary, i.e. a few words about the turbocharger

The turbine installed in internal combustion engines is designed to pump an additional portion of air under pressure into the combustion chamber. For what? Increasing the amount of oxygen in the unit increases the capacity of the unit. Compression of air consists in setting the turbine rotor in motion with the help of exhaust gases. In another part of it is a compression wheel that sucks air from the atmosphere through a filter. To keep oxygen from overheating, it enters the intake system, often equipped with an intercooler, i.e. air cooler. Only later does it enter the intake manifold.

Turbocharger and regeneration - what can go wrong in it?

In fact, a lot of things can fail during the operation of the turbine. Regeneration of the turbocharger is most often necessary due to the fact that it "takes" oil. Though she won’t “give” oil, but the overexpenditure of motor lubricant and the appearance of blue smoke from the exhaust pipe encourages you to look at the turbine. What does this smoke color mean? White smoke from the exhaust pipe usually indicates that coolant has entered the cylinders, blue smoke indicates burning engine oil, and black smoke simply indicates unburned oil, i.e. nozzles.

Why is the turbo eating oil?

The working elements inside it, that is, the core, are lubricated with oil. When the engine is turned off, the oil pressure drops and excess oil in the channels of the upper part of the engine and the engine drains into the oil sump. So, if you start quickly after starting, you will soon be wondering where to regenerate the turbocharger. Why? Because the oil will not be able to get to all the elements that require lubrication, and the rotor will begin to rotate rapidly.

Small turbochargers and regeneration - why are they especially stressed?

Small turbos (such as those present in 1.6 HDI 0375J6, 1.2 Tce 7701477904 or 1.8t K03) have a particularly hard life, as during operation, they spin at a speed of several hundred thousand revolutions per minute. Compared to 5-7 thousand revolutions in the case of an engine, this is really a lot. Therefore, the loads acting in them are very large and they easily fail if used improperly.

Negligence in the form of extended oil change intervals and aggressive driving cause rotating elements to leak oil into the intake. But that's not the only problem with turbochargers.

What else turbines suffer from - repair of other engine components

In addition to valves, seals and rotor blades that can break, the housing is also damaged. Sometimes there is so little cast iron that, despite its strength, it collapses. There is a leak in the system and air, instead of getting into the intake manifold, comes out. In this case, the regeneration of the turbocharger consists in replacing such an element with a new one or welding it.

The paddle shifters that control the geometry are also an important structural element. This is a small element, but a key one, and its damage affects the operation of the entire device. There is also a pear, i.e. vacuum regulator, which consists of a spring and a membrane. Under the influence of high temperature, it can simply be damaged and the boost pressure control will not work properly.

Find out what turbine regeneration is

In simple terms, we are talking about restoring it to factory condition by replacing damaged parts or repairing them (if possible). Given the above scenarios of possible failures, the amount of work is really large. However, it usually proceeds very similarly, according to a certain pattern.

The first step in rebuilding a turbocharger is to disassemble all parts to assess their condition. Thus, it is prepared for the replacement of individual components and cleaning. It must be remembered that it is dirt in the form of exhaust gases that is one of the factors that shorten the life of the turbine. In addition, giving the customer a dirty element after regeneration is not very professional. Here are the components of the subassembly:

● impeller;

● sealing plate;

● compression wheel;

● thermal gasket;

● plain and thrust bearing;

● sealing rings;

● repeller;

● partition;

● casing of the rotor shaft (core);

The mechanic checks the condition of all the above parts. For example, main rotor blades can be broken, the shaft is worn out, and variable geometry blades are burned out. All this needs to be washed well so that wear can be assessed.

Turbine and regeneration - what happens to it after flushing?

After a thorough wash, it's time to clean the elements with compressed air and abrasive products. Turbocharger regeneration should include not only a thorough cleaning of all parts, but also coating them with anti-corrosion agents.. Due to this, when installed on the engine, the cast-iron part of the turbine will not rust. A thorough check allows you to evaluate which elements need to be replaced with new ones, and which can still be successfully used.

The next step is speed weighing. This allows you to check whether the elements fit so well that they do not allow oil to seep into the compression wheel. Many DIY enthusiasts believe that it is possible to rebuild a turbine in their own garage. However, this is not recommended. It is impossible to determine if all the elements are assembled correctly after assembly and if the turbo does not require weighing.

How much does it cost to restore a turbine in a car?

The cost of spare parts varies and depends on the model. As you have already noticed, there are also a lot of elements that can be damaged. After all, the work of specialists must be added to the price. The price list (often) depends on the popularity and reputation of the workshop. However, the price ремонт turbochargers usually cost between 800 and 120 euros Of course, you can find cheaper, but also much more expensive offers.

What else can be done with the turbine to make the car more powerful?

Remanufacturing the turbocharger itself is a great way to achieve near-factory performance. It is also possible to increase the compression circle in it, which involves machining the cold side housing, driving it to a higher pressure, or simply replacing it with a larger one. Of course, it makes no sense to change such elements in serial engines, because sooner or later something will fail (for example, a clutch or shaft bearings). But this is a topic for another article.