Idle speed controller / stepper motor

Content

Designed for gasoline vehicles, the idle speed controller, also called actuator / solenoid valve / stepper motor, is designed to control the idle speed of your vehicle. Let's take a look at the details of this organ.

His role?

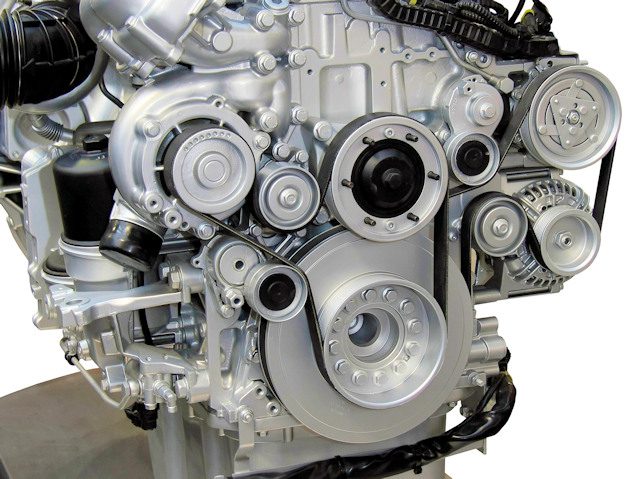

Therefore, the role is to regulate the idle speed so that it is stable and at the desired level (engine speed) on gasoline engines (on diesel engines, the throttle valve is not used to control or influence engine speed). Therefore, this is necessary because the idle speed fluctuation can be caused by several factors. For example, atmospheric pressure or temperature that changes (depending on the weather, altitude, etc.), And therefore the air is more or less loaded with oxygen / more or less dense. There are also ancillary devices that take (e.g. alternator, air conditioning compressor, power steering, etc.) energy from the engine through an accessory belt that is connected to the crankshaft and therefore receives little power from the engine. In short, as soon as something interferes with idling, the regulator should fix it.

Finally, it plays a role in the auto-choke principle, as it will regulate the air entering the intake to increase the engine speed (which limits the timing possibilities associated with thick oil and internal cold in the cylinders, which prevents the fuel from evaporating well: it condenses on walls and therefore does not burn completely or well). In addition to this, the mixture is enriched by supplying more fuel for “the same dose of air” (hence a richer mixture than stoichiometric, hence a higher level of cold smoke, even if this is not the only factor). Therefore, the throttle valve consists of a richer mixture and a slight increase in idle, and this is where the idle regulator comes into play, since it can regulate the amount of incoming air (always based on saturation).

All belt-driven attachments increase engine load, so idle speed should be adjusted as needed.

How does the idle speed regulator work?

The general principle of the idle speed regulator is to regulate the amount of air entering the engine to achieve a predetermined speed. If it is at 900 rpm, then the regulator will definitely leave the latter.

But if the principle is that, whatever the machine is, in practice there are two main processes:

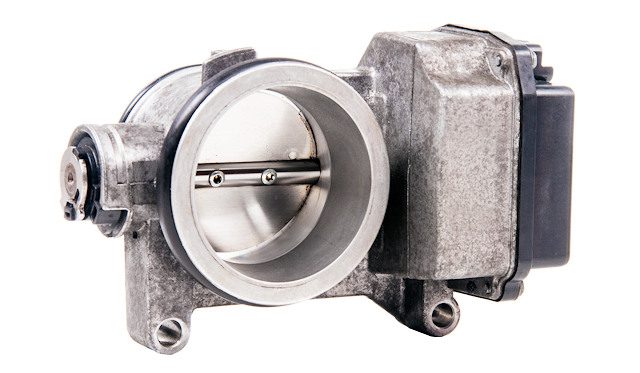

- Stepper motor

- The electric throttle body is considered to be motorized.

Stepper motor

The stepper motor is a small plug that is electrically controlled by a computer. Its drive (very precise when passing) works thanks to an electromagnetic force with the help of an electromagnet (a magnet controlled by a power source: the more I feed it, the more it becomes magnetized). This is also the most common process when something is controlled by a computer: the more energy it sends, the more it activates the mechanism.

In the case of a stepper motor, this involves opening more or less the secondary air inlet to compensate for the lack of air.

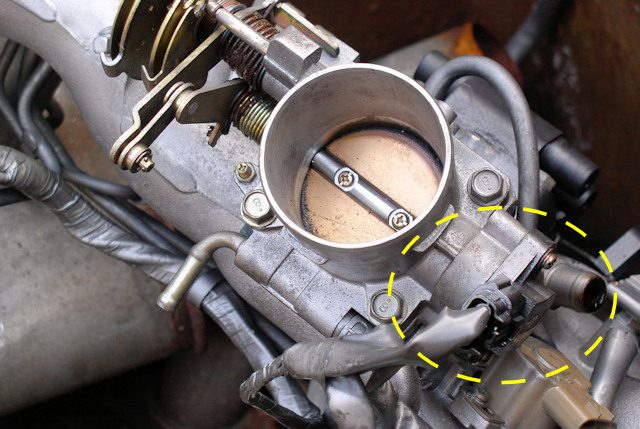

This is useful here when the throttle is controlled by the throttle cable. Thus, computer modulation of the air cannot be done in this way, because it is only controlled by the driver's foot.

When the throttle valve opens, the stepper motor closes.

Here is the stepper motor drive

When the throttle valve closes, the stepper motor controls the air flow to keep idle at the desired level.

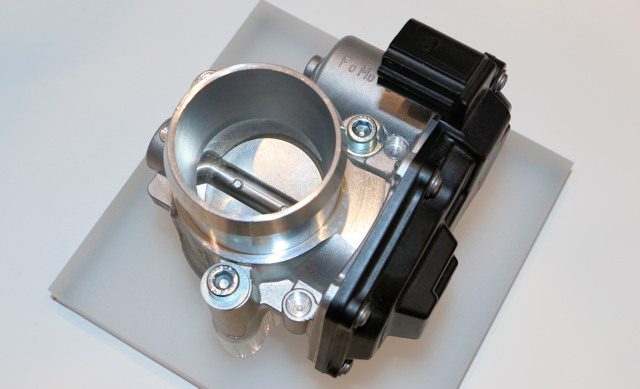

Motorized butterfly

In this case, the system is very simple, the computer controls the throttle valve using a potentiometer. It is no longer necessary to build in an additional system that controls the air intake at idle speed, it is a computer that modulates the tilt of the damper to allow more or less air to enter it. Hence, this is a modern regulatory system.

Your feedback

Below are testimonials automatically compiled from opinions written by Internet users on the site's test sheets. We invite all of you to leave a review about your car, if an ad exists.

Citroen Saxo (1996-2003)

1.4 i 75 ch : Cylinder head gasket, hs, step motor just kidding, no shell body parts found

Peugeot 306 (1993-2001)

1.8 112 hp Manual 5, 270, 000, R2001, Estate : catalytic converter for 125 rear, train for 000 driver's windows step motor air intake throttle up to 240 interior thruster up to 000 A damaged steering wheel requires a steering wheel to be installed. Rear doors and trunk that have already been replaced once, airbag warning light, dash and center console lighting that isn't 250%, dash with play, door seals that can sometimes let rain water in if the car isn't parked perfectly flat, the rest is wear and tear due to age/mileage, like things like paint, and sleeping outside with all the climate hazards.

Dacia Sandero (2008-2012)

1.6 MPI 90 channels : idle speed regulator ( step motor)

Peugeot 407 (2004-2010)

1.8 16v 115 hp Manual transmission, 138000 km, comfort pack : LCD display, damper pulley making scrap metal noise when accelerating. step motor The box is a little stiff

Peugeot 406 (1995-2004)

1.7 117 CH, El.) 16 V EW7J4 99 160 000 : step motor idle (solved by disassembly and cleaning), exhaust (normal), nothing shorter than 3 times.

Renault Kangoo (1997-2007)

1.4 petrol 75 hp, manual transmission, 80 km, 000s : mechanical; electrical part (TDC sensor) electric motor idle speed regulatore.

Renault Espace 3 (1997-2002)

2.0 16v 140 ch : Centralization of hs box without repair idle speed regulators4 ignition coils + 4 spark plugs 4 injectors Ect…. Mostly a financial hole

Peugeot 206 (1998-2006)

1.4 75 ch manual transmission, 2005, X-line air conditioner : 45000 km / 6 years change of tensioning roller + auxiliary belt 46000 km / 6 years step motor idle speed control 70000 9 km / 200085000 10 years airbag warning light is on -> replace COM93000 11 127000 km / 13 years clutch bearing HS 140000 15 km / XNUMX years steering rods and anti-roll bar, cooling radiator replacement XNUMX XNUMX km / XNUMX years problem contact on the ABS computer XNUMX XNUMX km / XNUMX without coolant leak in the radiator

Peugeot 106 (1991-2003)

1.1 60 h.p. XN Injection, 5-speed gearbox, 217000 km, 1995 : - bearing sensor and step motor dead => Unstable Slow ( step motor) and stalls if you stop accelerating (bearing sensor). After solving the problem, the power problem is because a dead lambda probe and a charred spark plug due to unstable deceleration and constant acceleration.

Citroen Berlin (1996-2008)

1.8 and 90 ch 180000 : Bought 3 years ago from 130000 km, today 180000 km Costs other than scheduled maintenance step motor replacement after 10 minutes and 40 Replacing the power window motor after 45 minutes and 25 on the LBC Replacing the rear door cylinder in 5 minutes and 35

BMW 3 Series Coupe (1999-2006)

318ci 118 HP 295000 16 km, PACK finish, sport chassis, XNUMX ″ alloy wheels : - HS fuel pump - Several hoses in the cooling circuit that fart one after another (not funny on the highway) - Faulty ignition harness - Coolant temperature sensor - Cooling radiator - Expansion tank cap - Faulty tail light contact - Triangles (silenblocks) which wear out pretty quickly (do not put sub-brand) - idle drive

Peugeot 106 (1991-2003)

1.4 gearbox 75 HP 5 year 1996 km 140 rim 000 inch 14 xs trim : step motor, intake pipe sensor

BMW Series 3 (1998-2005)

330i 230 ch 330CiA 185000 km 09/2000, rims 72M 18p : After poor quality maintenance of the flow meter, fuel pump, previous owner. idle drive

Peugeot 406 coupe (1997-2005)

2.0 16v 140 hp Manual transmission .230 microns 2001 16 inches space gray package : Fuel level sensor in the fuel pump idle drive retro int defective

Peugeot 206 (1998-2006)

1.6 90 HP Year 1998, second-hand, gearbox-2 gears, 5 thousand km (bought for 260 thousand km 160 years ago) 🇧🇷 idle speed regulator remove small things from time to time • By CO2 emission approx; Exhaust leaks and / or the classic wear period of the lambda probe • Front axle halves, weak wishbone bushings; unclear direction, reduction in the length of the road to be replaced between 50/80 miles, subject to confirmation depending on the quality of the parts • Gearbox; a level that needs to be checked regularly, even if it means emptying, to ensure the longevity of this beautiful, low-cost, short-service gearbox

Citroen Saxo (1996-2003)

1.0 i 50 ch : step motor / side contamination, cylinder head gasket, taillights

Peugeot 306 (1993-2001)

1.8 100 h.p. 306 ST manual transmission, 1996, 4 doors, 240000 km : idle speed regulators, air spring harness, headlight connector oxidation relay and headlight relay,

Peugeot 206 (1998-2006)

1.1 hp : unstable idle + step motor + coil + cylinder head gasket

Volkswagen Tiguan (2007-2015)

2.0 TDI 140 bhp 150000 : idle drive changed twice, fan off

Volkswagen Passat CC (2008-2016)

2.0 TDI 140 bhp 113000 : chips during acceleration, therefore it is necessary to replace the egr hs valve train, idle drive does not work

All comments and reactions

Dernier comment posted:

Hamid (Date: 2021, 10:18:15)

добро пожаловать

I have a peugeot 301 ess 1.6 vti 115 hp car, the problem says that it starts especially in the morning even after 10 minutes of ignition, or after 200-300 meters it starts to scratch e mm when accelerating, it is difficult for me to roll, so I turn off the engine and / or after a few seconds I turn it on again and it starts up again without any problem.

the problem persists for 2 months without a solution, the fuel pump was changed

changed clutch silence

the engine was overhauled

I tried ???????????

Il I. 1 reaction (s) to this comment:

- Honda4 BEST PARTICIPANT (2021-10-19 10:11:45): Engine overhaul?

Ignition problem and the mechanic didn't find anything?

Check candles, coils. You can see the nozzles, maybe even a computer.

(Your post will be visible under the comment after verification)

Write a comment

You change your car every: