Seat belts and seat belt tensioners

Content

The most common structural element of a car's passive safety system are seat belts. Its use reduces the likelihood and severity of injuries due to impacts on hard parts of the body, glass, and other passengers (so-called secondary impacts). Fastened seat belts ensure the effective operation of the airbags.

According to the number of attachment points, the following types of seat belts are distinguished: two-, three-, four-, five- and six-point.

Two-point seat belts (fig. 1) are currently used as the center seat belt in the back seat of some older cars, as well as in passenger seats on airplanes. The reversible seat belt is a lap belt that wraps around the waist and is attached to both sides of the seat.

Three-point seat belts (fig. 2) are the main type of seat belts and are installed on all modern cars. The 3-point diagonal waist belt has a V-shaped arrangement that evenly distributes the energy of the moving body to the chest, pelvis and shoulders. Volvo introduced the first mass-produced three-point seat belts in 1959. Consider the device three-point seat belts as the most common.

The three-point seat belt consists of a webbing, a buckle and a tensioner.

The seat belt is made of durable material and is attached to the body with special devices at three points: on the pillar, on the threshold and on a special rod with a lock. To adapt the belt to the height of a particular person, many designs provide for adjusting the height of the upper attachment point.

The lock secures the seat belt and is installed next to the car seat. A movable metal tongue is made to connect with the strap clasp. As a reminder of the need to wear a seat belt, the design of the lock includes a switch included in the circuit of the AV alarm system. Warning occurs with a warning light on the dashboard and an audible signal. The algorithm of this system is different for different car manufacturers.

The retractor provides forced unwinding and automatic rewinding of the seat belt. It is attached to the car body. The reel is equipped with an inertial locking mechanism that stops the movement of the belt on the reel in the event of an accident. Two methods of blocking are used: as a result of the movement (inertia) of the car and as a result of the movement of the seat belt itself. The tape can only be pulled off the spool drum slowly, without acceleration.

Modern cars are equipped with pretensioner seat belts.

Five-point seat belts (fig. 4) are used in sports cars and for securing children in child car seats. Includes two waist straps, two shoulder straps and one leg strap.

Rice. 4. Five-point harness

The 6-point safety harness has two straps between the legs, which provides a more secure fit for the rider.

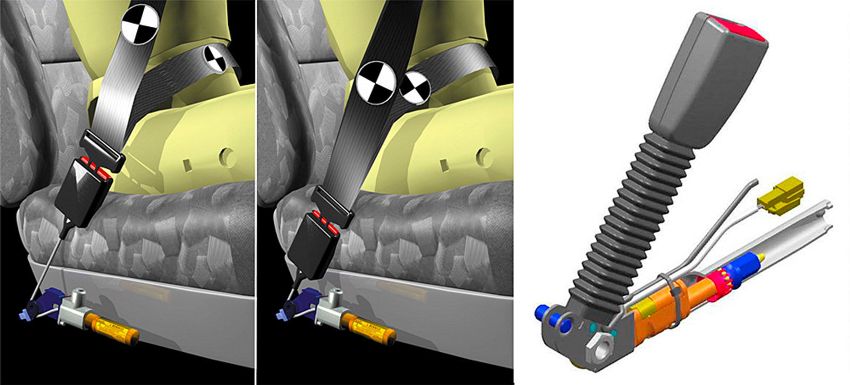

One of the promising developments is inflatable seat belts (Fig. 5), which are filled with gas during an accident. They increase the area of contact with the passenger and, accordingly, reduce the load on the person. The inflatable section may be a shoulder section or a shoulder and waist section. Tests show that this seat belt design provides additional side impact protection.

Rice. 5. Inflatable seat belts

Ford offers this option in Europe for the fourth generation Ford Mondeo. For passengers in the back row, inflatable seat belts are installed. The system is designed to reduce head, neck and chest injuries in the event of an accident for rear row passengers, who are often children and the elderly, who are particularly prone to these types of injuries. In everyday use, inflatable seat belts work the same as regular ones and are compatible with child seats.

In the event of an accident, the shock sensor sends a signal to the security system control unit, the unit sends a signal to open the shut-off valve of the carbon dioxide cylinder located under the seat, the valve opens and the gas that was previously in a compressed state fills the seat belt cushion. The belt deploys quickly, distributing the impact force over the surface of the body, which is five times more than standard seat belts. The activation time of the straps is less than 40ms.

With the new Mercedes-Benz S-Class W222, the company is expanding its rear-seat passenger protection options. The rear seat PRE-SAFE package combines pretensioners and an airbag in the seat belt (Beltbag) with airbags in the front seats. The combined use of these devices during an accident reduces passenger injuries by 30% compared to the traditional scheme. The seat belt airbag is a seat belt capable of inflating and thereby reducing the risk of injury to passengers in a frontal collision by reducing the load on the chest. The reclining seat is equipped as standard with an airbag hidden under the upholstery of the seat cushion. Such a cushion will prevent the passenger in a reclining position from slipping under the seat belt in the event of an accident (so-called "diving"). In this way, Mercedes-Benz has been able to develop a comfortable reclining seat that provides a greater level of safety in the event of an accident than a seat in which the backrest is reclined by extending the seat cushion.

As a measure against the non-use of seat belts, automatic seat belts have been proposed since 1981 (Fig. 6), which automatically secure the passenger when the door is closed (engine start) and release him when the door is opened (engine start stop). As a rule, the movement of the shoulder belt moving along the edges of the door frame is automated. The belt is fastened by hand. Due to the complexity of the design, the inconvenience of getting into a car, automatic seat belts are currently practically not used.

Rice. 6. Automatic seat belt

2. Seat belt tensioners

At a speed of, for example, 56 km/h, it takes about 150 ms from the moment of collision with a fixed obstacle to a complete stop of the car. The driver and passenger of the car do not have time to perform any actions in such a short period of time, therefore they are passive participants in the emergency. During this period, the seat belt pretensioners, airbags, and battery kill switch must be activated.

In an accident, seat belts must absorb an energy level roughly equal to the kinetic energy of a person falling from the fourth floor of a high-rise building. Due to the possible loosening of the seat belt, a pretensioner (pretensioner) is used to compensate for this loosening.

The seat belt tensioner retracts the seat belt in the event of a collision. This helps reduce seat belt slack (the space between the seat belt and the body). Thus, the seat belt prevents the passenger from moving forward (in relation to the movement of the car) in advance.

Vehicles use both diagonal seat belt pretensioners and buckle pretensioners. Using both types allows you to optimally fix the passenger, since in this case the system pulls the buckle back, while simultaneously tightening the diagonal and ventral branches of the seat belt. In practice, tensioners of the first type are mainly installed.

The seat belt tensioner improves tension and improves belt slippage protection. This is achieved by immediately deploying the seat belt pretensioner during the initial impact. The maximum movement of the driver or passenger in the forward direction should be about 1 cm, and the duration of the mechanical action should be 5 ms (maximum value 12 ms). The tensioner ensures that the belt section (up to 130 mm long) is wound up in almost 13 ms.

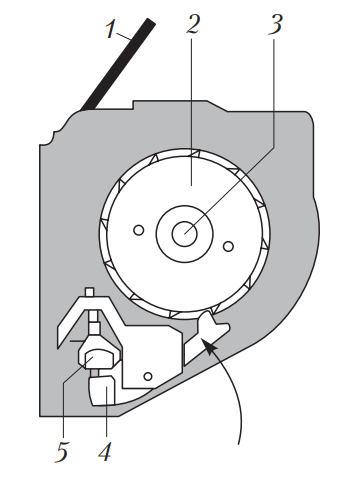

The most common are mechanical seat belt pretensioners (Fig. 7).

Rice. 7. Mechanical seat belt tensioner: 1 - seat belt; 2 - ratchet wheel; 3 - axis of the inertial coil; 4 - latch (closed position); 5 - pendulum device

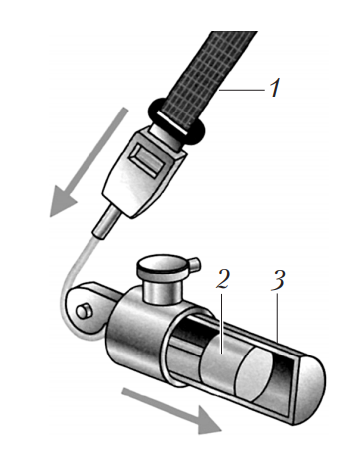

In addition to traditional mechanical tensioners, many manufacturers are now equipping vehicles with pyrotechnic tensioners (Figure 8).

Rice. 8. Pyrotechnic tensioner: 1 - seat belt; 2 - piston; 3 - pyrotechnic cartridge

They are activated when the system's built-in sensor detects that a predetermined deceleration threshold has been exceeded, indicating the start of a collision. This ignites the detonator of the pyrotechnic cartridge. When the cartridge explodes, gas is released, the pressure of which acts on the piston connected to the seat belt. The piston moves quickly and tensions the belt. Typically, the response time of the device does not exceed 25 ms from the start of the discharge.

To avoid overloading the chest, these belts have tension limiters that work as follows: first, the maximum allowable load is reached, after which a mechanical device allows the passenger to move a certain distance forward, keeping the charge level constant.

According to the design and principle of operation, the following types of seat belt tensioners are distinguished:

- cable with a mechanical drive;

- ball;

- turning;

- shelf;

- reversible.

2.1. Cable tensioner for seat belt

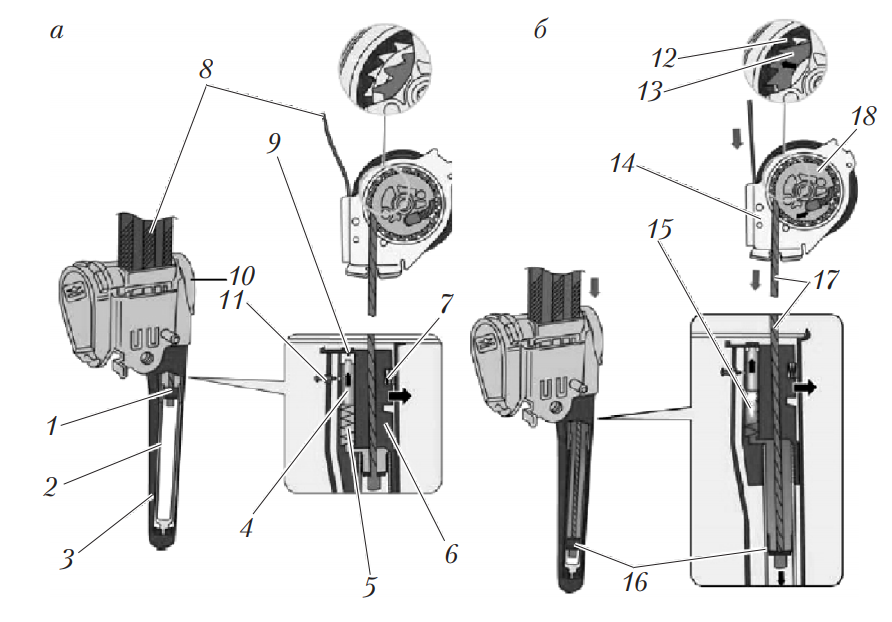

The seat belt tensioner 8 and the automatic seat belt reel 14 are the main components of the cable tensioner (Fig. 9). The system is movably fixed on the protective tube 3 in the bearing cover, similarly to a vertical pendulum. A steel cable 1 is fixed on the piston 17. The cable is wound and installed on a protective tube on the drum 18 for the cable.

The tension module consists of the following elements:

- sensors in the form of a "spring-mass" system;

- gas generator 4 with a pyrotechnic propellant charge;

- piston 1 with a steel cable in the tube.

If the deceleration of the car during a collision exceeds a certain value, then the sensor spring 7 begins to compress under the action of the sensor mass. The sensor consists of a support 6, a gas generator 4 with a pyrotechnic charge ejected by it, a shock spring 5, a piston 1 and a tube 2.

Rice. 9. Cable tensioner: a - ignition; b - voltage; 1, 16 - piston; 2 - tube; 3 - protective tube; 4 - gas generator; 5, 15 - shock spring; 6 - sensor bracket; 7 - sensor spring; 8 - seat belt; 9 - shock plate with a shock pin; 10, 14 - seat belt winding mechanism; 11 - sensor bolt; 12 - gear rim of the shaft; 13 - toothed segment; 17 - steel cable; 18 - drum

If the support 6 has moved a distance greater than the norm, the gas generator 4, held at rest by the sensor bolt 11, is released in the vertical direction. The stressed impact spring 15 pushes it towards the impact pin in the impact plate. When the gas generator hits the impactor, the gas generator float charge ignites (Fig. 9, a).

At this time, the gas is injected into the tube 2 and moves the piston 1 with the steel cable 17 down (Fig. 9, b). During the first movement of the cable wound around the clutch, the toothed segment 13 moves radially outward from the drum under the action of the acceleration force and engages with the toothed rim of the shaft 12 of the seat belt winder 14.

2.2. Ball belt tensioner

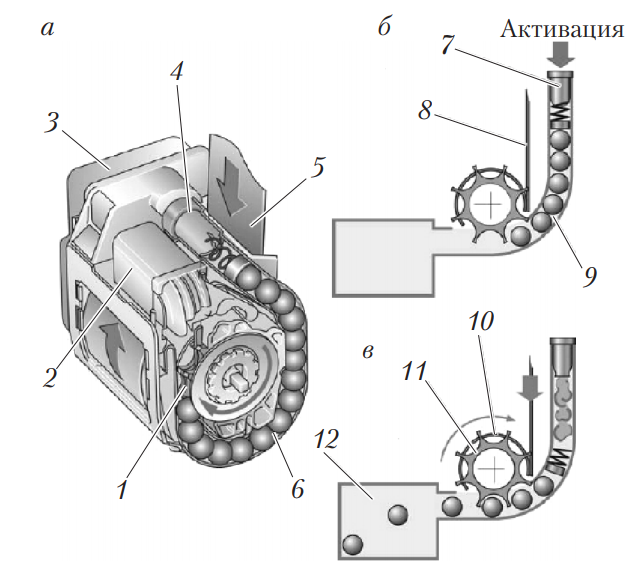

It consists of a compact module which, in addition to belt recognition, also includes a belt tension limiter (fig. 10). Mechanical actuation only occurs when the seat belt buckle sensor detects that the seat belt is fastened.

The ball seat belt pretensioner is actuated by balls placed in the tube 9. In the event of a collision, the airbag control unit ignites the ejecting charge 7 (Fig. 10, b). In electric seat belt tensioners, the activation of the drive mechanism is carried out by the airbag control unit.

When the ejected charge is ignited, the expanding gases set the balls in motion and direct them through the gear 11 into the balloon 12 to collect the balls.

Rice. 10. Ball tensioner: a - general view; b - ignition; c - voltage; 1, 11 - gear; 2, 12 - balloon for balls; 3 - drive mechanism (mechanical or electric); 4, 7 - pyrotechnic propellant charge; 5, 8 - seat belt; 6, 9 - tube with balls; 10 - seat belt winder

Since the seat belt reel is rigidly connected to the sprocket, it rotates with balls, and the belt retracts (Fig. 10, c).

2.3. Rotary belt tensioner

Works on the principle of a rotor. The tensioner consists of a rotor 2, a detonator 1, a drive mechanism 3 (Fig. 11, a)

The first detonator is driven by a mechanical or electric drive, while the expanding gas rotates the rotor (Fig. 11, b). Since the rotor is connected to the belt shaft, the seat belt begins to retract. Upon reaching a certain angle of rotation, the rotor opens the bypass channel 7 to the second cartridge. Under the action of working pressure in chamber No. 1, the second cartridge ignites, due to which the rotor continues to rotate (Fig. 11, c). Flue gases from chamber No. 1 exit through the outlet channel 8.

Rice. 11. Rotary tensioner: a - general view; b - the action of the first detonator; c - action of the second detonator; g - the action of the third firecracker; 1 - bait; 2 - rotor; 3 - drive mechanism; 4 - seat belt; 5, 8 - output channel; 6 - work of the first bait; 7, 9, 10 - bypass channels; 11 - actuation of the second detonator; 12 - chamber No. 1; 13 - performance of the third bait; 14 - camera number 2

When the second bypass channel 9 is reached, the third cartridge is ignited under the action of the working pressure in chamber No. 2 (Fig. 11, d). The rotor continues to rotate and the exhaust gas from chamber No. 2 exits through outlet 5.

2.4. Belt tensioner

For a smooth transfer of force to the belt, various rack and pinion devices are also used (Fig. 12).

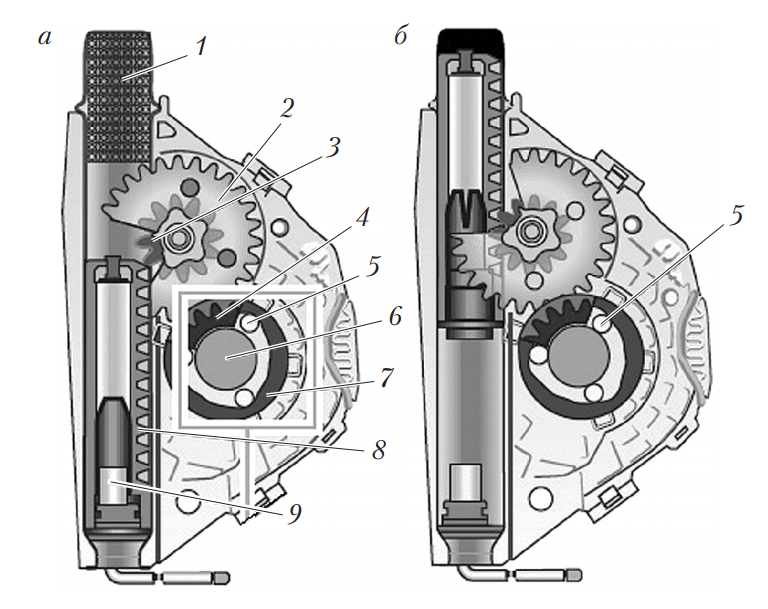

Rack tensioner works as follows. At the signal of the airbag control unit, the detonator charge ignites. Under the pressure of the resulting gases, the piston with the rack 8 moves up, causing the rotation of the gear 3, which is engaged with it. The rotation of gear 3 is transmitted to gears 2 and 4. Gear 2 is rigidly connected to the outer ring 7 of the overrunning clutch, which transmits torque to the torsion shaft 6. When the ring 7 rotates, the rollers 5 of the clutch are clamped between the clutch and the torsion shaft. As a result of the rotation of the torsion shaft, the seat belt is tensioned. Belt tension is released when the piston reaches the damper.

Rice. 12. Seat belt tensioner: a - starting position; b - the end of the belt tension; 1 - shock absorber; 2, 3, 4 - gears; 5 - roller; 6 - axis of torsion; 7 - the outer ring of the overrunning clutch; 8 - piston with rack; 9 - firecracker

2.5 reversible belt tensioner

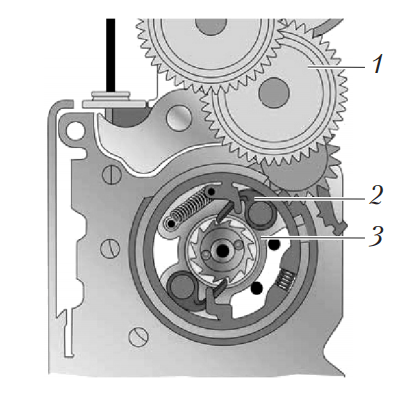

In more complex passive safety systems, in addition to pyrotechnic seat belt pretensioners, a reversible seat belt pretensioner (Fig. 13) with a control unit and an adaptive seat belt force limiter (switchable.

Each reversible seat belt pretensioner is controlled by a separate control unit. Based on data bus commands, the seat belt pretensioner control units actuate the connected actuating motors.

Reversible tensioners have three levels of actuation force:

- low effort - selection of slack in the seat belt;

- average force - partial tension;

- high strength - full tension.

If the airbag control unit detects a minor frontal collision that does not require the pyrotechnic pretensioner, it sends a signal to the pretensioner control units. They command the seat belts to be fully tensioned by the drive motors.

Rice. 13. Seat belt with reversible pretensioner: 1 - gear; 2 - hook; 3 - leading drive

The motor shaft (not shown in Fig. 13), rotating through a gear, rotates a driven disk connected to the seat belt shaft by two retractable hooks. The seat belt wraps around the axle and tightens.

If the motor shaft does not rotate or rotates slightly in the opposite direction, the hooks may fold in and release the seat belt shaft.

The switchable seat belt force limiter is activated after the pyrotechnic pretensioners have been deployed. In this case, the locking mechanism blocks the belt axis, preventing the belt from unwinding due to the possible inertia of the bodies of passengers and the driver.