Do-it-yourself CV joint puller: design and principle of operation, types, drawings and step-by-step instructions

Content

When repairing a car in a garage, a puller is indispensable. It can be bought at the store, but some drivers prefer to save money and make their own. Using a homemade tool, you can easily replace the outer boot and remove the grenade from the car without removing the box.

If you make a CV joint puller with your own hands, you can save time and effort when repairing a car. With this tool, it is easy to replace the elements of a ball bearing assembly without contacting a service center.

SHRUS device

The constant velocity joint is the part of the chassis of a car that transmits the driving force from the engine to the wheels. Due to the peculiarity of the structure of the mechanism, the machine can drive evenly even on uneven surfaces.

While driving CV joint:

- removes the load from the drive shaft;

- dampens vibration;

- synchronizes the wheels.

The design of the hinge is a bearing assembly with a floating separator. The hub and axle shaft of the suspension of the machine are attached to its edges. Because of the appearance, this transmission element is also called a “grenade”.

SHRUS device

The CV joint consists of 2 parts:

- External, connects the wheel hub and functions at angles up to 70°.

- Internal, attached to the actuator and operating in the 20° range.

Inside the CV joint there is a cage with metal bearings, which includes the axle shaft. The running unit is fixed using splines and a spring stopper located in a separate groove on the shaft. It is very difficult to separate such fasteners without special tools.

Principle of operation of the puller

The tool is a mechanism that is attached to the half-axle with some bolts, while others squeeze the inside of the grenade out. Depending on the type of devices, the methods of use differ.

The inertial CV joint puller works on the principle of a reverse hammer. One part of the tool is mounted to the shank, the other, with a sliding weight, is fixed on the axle shaft with the help of an eye. With a sharp movement of the cylindrical load in the opposite direction from the part, the hinge is removed from the spline connection without damage.

To dismantle the grenade using the wedge method, you will need a tool with 2 support platforms. One consists of clamps that are put on the axial connection. The other is a split ring for the hinge cage. Between them, on the sides, wedges are hammered with hammers. After a couple of blows, the axle shaft moves a few millimeters, releasing the part from the stopper.

CV joint puller in action

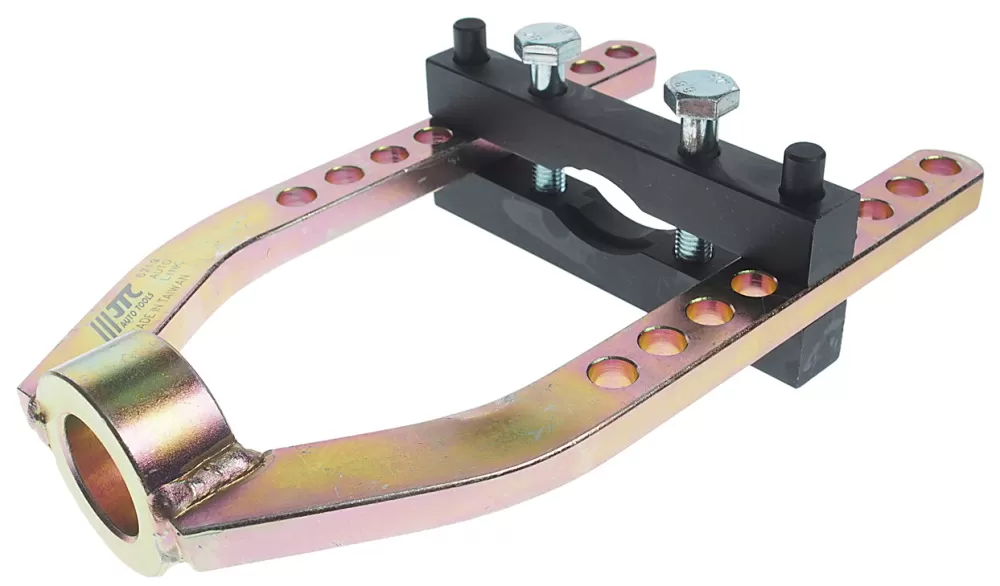

The screw extractor is suitable for working with fasteners of any size. Consists of 2 sliding platforms. They are interconnected by longitudinal plates. On each there are holes that are needed to adjust the working distance. One platform is fixed with a clamp, the second is fixed with a pharynx on the spline connection of the shaft. Then turn the hub nut until the retaining ring clicks. After that, the hinge can be removed without effort.

Varieties

Pullers are distinguished by the method of extracting the CV joint from the suspension of the machine. The following 3 types are common:

- universal;

- with steel cable;

- with reverse hammer.

A universal puller is needed to remove grenades from most front- and all-wheel drive vehicles. The tool consists of 2 clamps with an eyelet in the center. They are fixed on the shaft. When tightening the hub nut, the hinge is released from the stopper.

A steel cable puller is designed to quickly remove the CV joint. The loop is thrown on the base of the hinge and the grenade is pulled out of the hub with a sharp pickup.

CV joint puller with steel cable

The reverse hammer tool is an inertial device for safely dismantling the chassis suspension using a moving “weight”.

How to make from improvised materials

When repairing a car in a garage, a puller is indispensable. It can be bought at the store, but some drivers prefer to save money and make their own. Using a homemade tool, you can easily replace the outer boot and remove the grenade from the car without removing the box.

For the manufacture of the simplest device, you will need scrap metal and a welding machine. Before proceeding with the assembly, it is recommended to watch video reviews and do-it-yourself CV joint puller drawings on the Internet. Then proceed according to the following algorithm:

- Take a 7mm thick steel sheet and cut 4 identical strips.

- Weld them in pairs with each other to get 2 plates 14 mm thick.

- Cut out 2 “bends” from the rest of the metal and weld all the workpieces to a piece of pipe.

- From steel, make a clamp for the shaft with an upper and lower jaw.

- Fix the structure in the center of the pipe

- Weld long metal plates to the sponges.

- Drill holes on the sides of the clamp and in the "knees".

SHRUS puller from improvised materials

The tool is ready for use, it remains to clean it with a grinder and paint it. The disadvantage of the device is in the possible deformation under heavy loads. To avoid this, it is necessary to make the clamping jaws from sheet metal 15 mm thick.

You can assemble an external CV joint puller with your own hands, working on the principle of a reverse hammer, from reinforcement. On it, weld a transverse eye to the size of the tail of the hub. Insert a heavy sledgehammer with a through hole into the reinforcement, and install a shock-resistant stopper at its other end.

When should a puller be used?

For timely repair of the chassis of the car and replacement of the CV joint, it is important to pay attention to the characteristic features:

- rhythmic knocking, creaking and grinding when accelerating and turning;

- vibration and jolts when trying to shift gear;

- strong steering play.

The cause of defects may be water and dirt that got into the grenade due to a torn anther. Such malfunctions occur during aggressive driving, especially if you sharply accelerate with the wheels completely unscrewed.

There is no need to go to a service station for troubleshooting. You can replace the anther and the hinge yourself and for free, if you make a universal CV joint puller with your own hands. It will not be difficult to make this device if you have a welding machine and basic skills in working with a grinder.