Homemade paint thickness gauge

Content

A simple device can be assembled with your own hands from a permanent magnet placed in a homemade case. The assembled paintwork thickness gauge with their own hands determines the height of the layer by the force that must be expended on separation from the magnetized metal.

When buying a used car, they usually check the quality of the coating, the height of the paint layer and putty. You can make a simple do-it-yourself paintwork thickness gauge from ordinary materials. But for results with high accuracy, a more complex device is needed, the assembly of which requires knowledge.

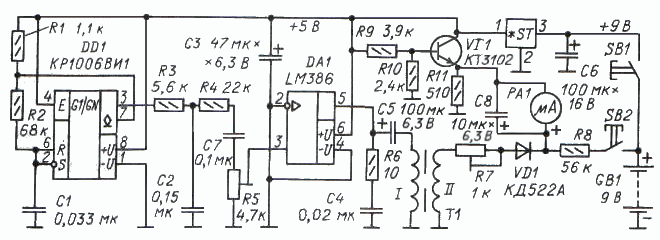

Diagram of an electric thickness gauge

A device for determining the height of the dielectric layer between metal surfaces is made according to a simple plan. The device is light in weight and is suitable for autonomous operation. The scheme of a home-made paintwork thickness gauge is based on the ideas of Yu. Pushkarev, the author of an article in the Radio magazine, 2009.

Therefore, by the level of the generated magnetic field, it is possible to determine the thickness of the paintwork on the surface of the car. The larger the dielectric layer, the lower the voltage on the secondary winding of the transformer.

The signal measured with an ammeter is inversely proportional to the height of the non-magnetic material. A self-made thickness gauge determines the depth of coloring within narrow limits. With a paintwork height of more than 2,5 mm, the measurement error increases. The normal range of car body paint thickness is between 0,15-0,35 mm, depending on the material.

Do-it-yourself paintwork meter

Often, when determining places on the body of a car with applied putty, a permanent magnet is sufficient. A more accurate result can be obtained using a homemade device. For a detailed examination of the coating of the car, a do-it-yourself thickness gauge is made according to the improved Pushkarev scheme.

To do this, a circuit is assembled from a high-frequency generator, a signal regulator and a transformer without top plates. A self-made paintwork thickness gauge allows you to determine the height of the paintwork layer with an accuracy of 0,01 mm.

Checking the quality of car painting

A simple device can be assembled with your own hands from a permanent magnet placed in a homemade case. The assembled paintwork thickness gauge with their own hands determines the height of the layer by the force that must be expended on separation from the magnetized metal.

If the coating layer on the surface of the machine is uniform, then the magnet moves away everywhere with the same force. But even repainted areas will differ from the base coat applied on the conveyor. An assembled do-it-yourself paintwork thickness gauge is useful when checking a used car for body repairs.

Necessary materials and tools for a simple device

For a complex device with an ultrasonic or electrical circuit, some preparation is needed. For domestic purposes, they manage with a meter from improvised items.

Materials and tools for a simple do-it-yourself paintwork thickness gauge:

- neodymium alloy permanent magnet;

- tubes with different diameters made of plastic;

- clerical rubber ring;

- glue and tape;

- knife;

- file.

The device has little accuracy, but it easily determines the difference in the height of the paint layer of 0,1-0,2 mm. Instead of tubes, you can take a used disposable syringe with the rubber band on the stem removed.

Stages of manufacturing a homemade LKP thickness gauge

A device for measuring the depth of color is assembled independently from improvised materials in a few minutes.

The sequence of manufacturing a do-it-yourself paintwork thickness gauge on a car body:

- Take a small magnet from old earphones or paper holders.

- Shorten the plastic tubes to the same length of approx. 100 mm.

- Glue a magnet to the end of a homemade device.

- Secure the rubber band with electrical tape and heal on a larger diameter tube.

- Put marks on the plastic surface to determine the thickness of the paintwork.

To measure a homemade paintwork thickness gauge, you need to pull off the free tube and detect at what risk the device will bounce off the surface of the car.