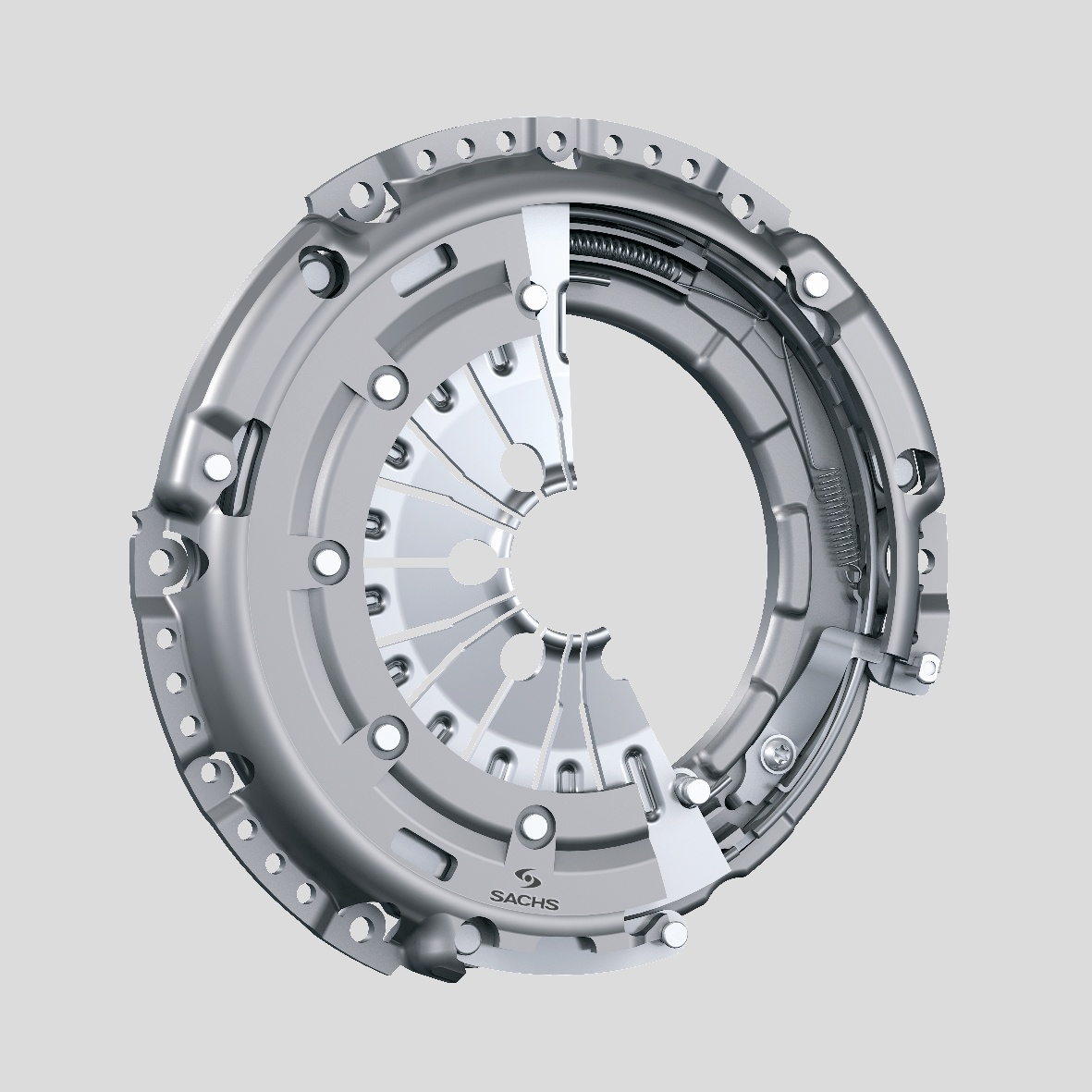

Self-adjusting XTend clutch assembly

Transmission manufacturers, including ZF, are constantly striving to automate transmission systems to improve performance, efficiency and ride comfort. An example of such a solution is the SACHS XTend self-adjusting clutch, which independently adjusts its settings during operation, depending on the wear of the linings.

Transmission manufacturers, including ZF, are constantly striving to automate transmission systems to improve performance, efficiency and ride comfort. An example of such a solution is the SACHS XTend self-adjusting clutch, which independently adjusts its settings during operation, depending on the wear of the linings.

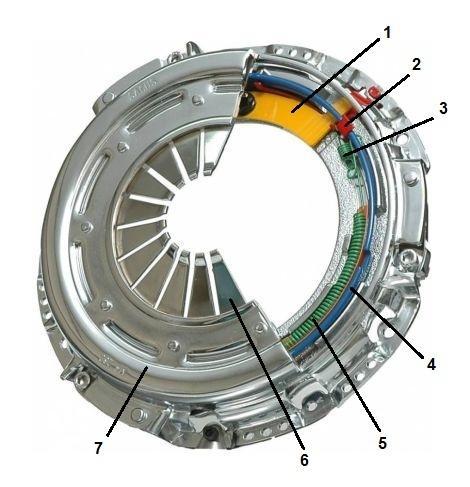

In XTend clutch pressure plates, in both push and pull clutches, the issue of lining wear resulted in  increase in steering effort, it was decided due to the fact that the movement of the diaphragm spring became independent of the degree of wear of the linings. For this, an equalizing mechanism is provided between the Belleville spring and the pressure plate.

increase in steering effort, it was decided due to the fact that the movement of the diaphragm spring became independent of the degree of wear of the linings. For this, an equalizing mechanism is provided between the Belleville spring and the pressure plate.

How XTend works

Pad wear changes the position of the diaphragm spring as the pressure plate moves towards the flywheel. The spring sheets are axially offset and more vertical so that the pressure force and hence the force required to depress the clutch pedal is greater.

With XTend clutches, each time the clutch is engaged, body resistance registers lining wear and moves the retaining spring away from the set rings by the amount of wear. A wedge slider slides into the resulting gap, pulled up by its spring, setting the retaining spring.

in the raised position. When the clutch is disengaged, the pair of adjusting rings is unloaded in the axial direction. When the set ring spring is pretensioned, the lower ring rotates until the upper ring rests against the set spring. Thus, the Belleville spring returns to its original position and the lining wear is compensated.

Disassembly

When disassembling this type of clutch, it should be remembered that if the housing resistance is not removed, the adjustment mechanism will work and it will be impossible to restore the original setting. Due to the fact that the wear of the pads is mechanically “stored” in the clutch cover, the assembly of the previous assembly is only possible in its entirety. If the disc needs to be replaced, new pressure must also be taken care of - the pressure equalization mechanism used cannot be returned to its original position, so it will not be possible to disengage the clutch.

When disassembling this type of clutch, it should be remembered that if the housing resistance is not removed, the adjustment mechanism will work and it will be impossible to restore the original setting. Due to the fact that the wear of the pads is mechanically “stored” in the clutch cover, the assembly of the previous assembly is only possible in its entirety. If the disc needs to be replaced, new pressure must also be taken care of - the pressure equalization mechanism used cannot be returned to its original position, so it will not be possible to disengage the clutch.

installation

XTend Clamps are equipped with a self-adjusting locking mechanism that operates on the self-locking principle. Therefore, you should not throw or drop them - the vibration rings can move and change the settings. Also, such a clamp cannot be washed, for example, with diesel fuel, as this can change the coefficient of friction of the seating surfaces and interfere with the correct operation of the clamp. Only possible cleaning with compressed air is enabled.

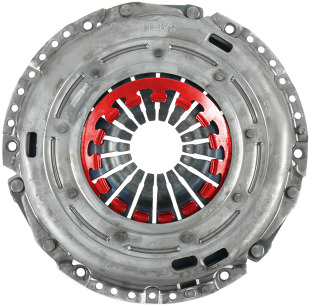

The XTend clamp should be tightened crosswise, tightening the screws only one or two turns. Particular attention during assembly should be given to the correct location of the belleville spring, which can be assisted by special tools. Under no circumstances should the spring be tightened with more force than recommended by the vehicle manufacturer.

A correctly replaced pressure clutch should have the ends of the central spring at an angle after installation.  directly to the axis of the input shaft.

directly to the axis of the input shaft.

After installation,

After installing the XTend clutch, it is worth using the “learning” procedure for it, as a result of which the pressure setting and the position of the release bearing are automatically corrected. This happens automatically when the diaphragm spring is pressed for the first time. After such assembly, the clutch should work properly.

As can be seen above, self-adjusting collar couplings are a little more difficult to assemble than traditional solutions, but when done correctly, guarantees safe and long-term operation.