Self-adjustment of the hydraulic drive and assessment of the need to replace the clutch VAZ 2107

Content

The VAZ 2107 clutch is designed to connect the engine crankshaft and the gearbox input shaft with the possibility of a short-term interruption of torque transmission. The reasons for its failure can be very diverse. Nevertheless, all of them can be easily diagnosed and eliminated on their own.

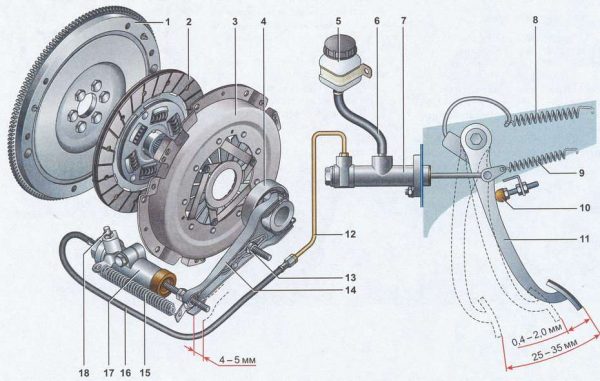

Clutch mechanism device VAZ 2107

The VAZ 2107 clutch is a rather complex mechanism, consisting of several dozen elements. The reasons for its failure can be very different. However, all of them can be divided into two groups:

- Defects in the clutch mechanism itself. These include malfunctions of the driven part of the clutch, pressure device, basket, flywheel, clutch on / off fork.

- Defects in the hydraulic drive of the clutch mechanism. They can be caused by leakage of the working fluid, the formation of an air plug in it, as well as malfunctions of the main or working cylinders (GCC and RCS) and the pedal mechanism.

The clutch, like any other part of the car, has a limited service life. First of all, it depends on the skill of the driver, therefore it is not regulated by the manufacturer. To increase the service life of the clutch, it is necessary to adjust it in time, monitor the level of the working fluid, avoid off-road driving, and learn how to properly use the clutch.

It must be remembered that, in addition, the clutch is a safety device that protects the transmission from serious damage when the rear wheels are blocked by various obstacles. The car got into a quagmire, the drive wheels got stuck, the engine power is enough to turn the stuck tires. In this case, the clutch will begin to slip, protecting the box, cardan and rear axle from damage. Yes, the lining of the driven disk will burn. Yes, the clutch will overheat, which can warp the steel flats or weaken the spring plates. But more expensive units will be protected from breakdowns.

On classic VAZ models, a dry, permanently closed single-plate clutch is installed.. It includes two main elements:

- Leading part. It consists of a driven disk, the splined part of which transmits rotation to the gearbox due to friction between the friction linings and the surfaces of the flywheel and pressure plate.

- Non-separable leading node (basket). The basket is attached to the flywheel and consists of a pressure plate and a diaphragm pressure spring.

The clutch mechanism must be reliable, durable, able to dampen fluctuations in engine torque. The clutch has a hydraulic drive, consisting of:

- clutch master cylinder;

- clutch slave cylinder;

- clutch on / off forks;

- release bearing;

- foot pedal.

Reasons for replacing and adjusting the clutch VAZ 2107

Replacing the VAZ 2107 clutch is a rather labor-intensive and expensive process. Therefore, before replacing, you should consider adjusting the mechanism.

Replacing the clutch

To install a new clutch, you will need a viewing hole, overpass or lift. It is important to detect signs in time that indicate the need to replace the clutch (it is impossible to replace it on the road), and drive the car to a garage or car service. Driving with a defective clutch is very dangerous - you can get into an accident when crossing a railway crossing or main road.

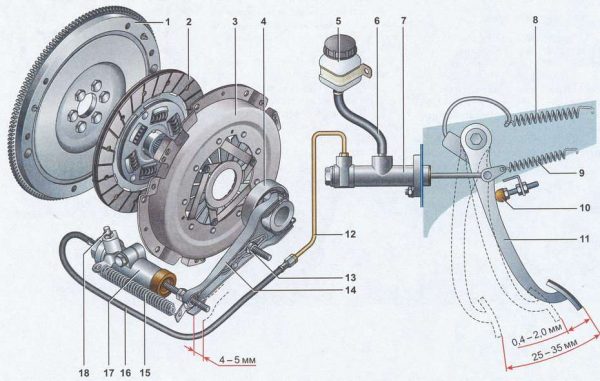

The entire VAZ 2107 clutch is changing, so a kit is sold in car dealerships, consisting of a driven disk, a basket and a release bearing. You should think about replacing the clutch in the following cases:

- the car rises heavily uphill with the accelerator pedal fully depressed, while the smell of burning is felt - these are signs of slipping of the driven part of the clutch;

- when the clutch is disengaged, noises appear in the area of \uXNUMXb\uXNUMXbthe flywheel housing - this indicates a malfunction of the release bearing;

- when starting the car, the first speed is hardly turned on (the box “growls”) - this is a sign of the clutch not fully disengaged (the clutch leads);

- when accelerating, the car starts to twitch, rattling sounds are heard - the reason for this is usually broken damper springs or loose nests for them on the driven disk, deformation of the segments or loosening of the rivets on the hub.

Any noise, vibration, whistling in the clutch area requires a more detailed diagnosis and diagnosis.

Clutch adjustment

If the clutch pedal has become too soft, fails, does not return to its original position, then most likely air has entered the system or the hydraulic drive adjustments have been violated. Clutch slippage after prolonged use usually indicates a clutch failure. It will definitely have to be changed.

If the clutch leads, that is, the gears are switched with difficulty, in about half of the cases the reason is a mismatch with the required values:

- backlash between the rod and the piston in the working cylinder;

- clearance between the release bearing and the fifth basket;

- free and working stroke of the foot pedal.

Diagnostics of malfunctions of clutch VAZ 2107

External manifestations of a VAZ 2107 clutch malfunction are:

- difficulty shifting gears;

- slippage of the driven part;

- vibration;

- thrust bearing whistle;

- tight pedal assembly;

- the pedal does not return to its original position after pressing;

- other signs.

Clutch slip

You can check if the clutch is slipping as follows. The third or fourth speed is turned on and the handbrake is pulled. If the motor hums, the car does not move, and the smell of burning has appeared in the cab, it means that the driven part of the clutch is slipping. This can happen for several reasons.

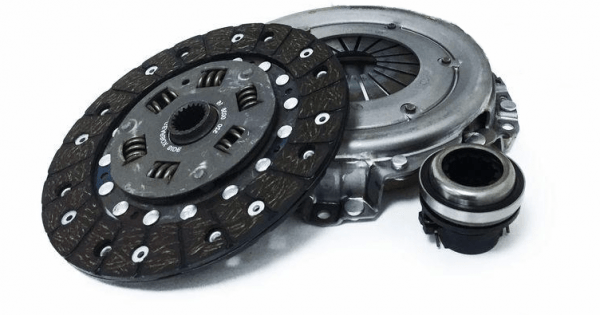

- The pedal has little play. If the problem is discovered after replacing the clutch, the cause is incorrect adjustment of the hydraulic drive. Lack of clearance between the thrust bearing and the fifth basket results in the driven disc not being clamped properly. It is necessary to adjust the length of the pusher by setting a play of 4–5 mm.

- When starting off or while driving uphill, the clutch burns, that is, acrid smoke begins to go from below. This indicates wear or burning of the lining of the driven disk, made of a friction-resistant composite material. In this case, the clutch must be replaced.

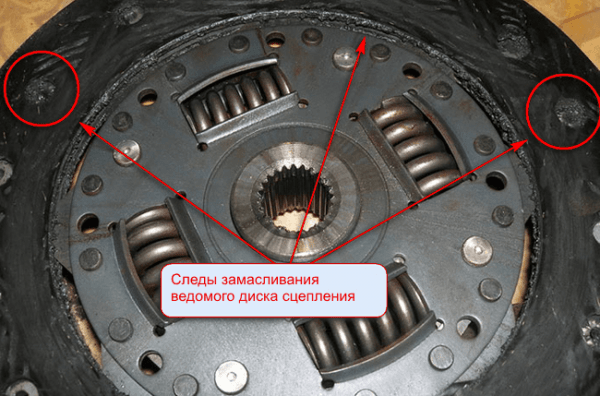

The lining of the driven disc, the surface of the flywheel and the pressure plate are oiled with grease that enters the clutch from the crankcase or gearbox

The lining of the driven disc, the surface of the flywheel and the pressure plate are oiled with grease that enters the clutch from the crankcase or gearbox - If the clutch simply slips, but does not burn (no smoke or smell), the lining of the driven part has been oiled. In this situation, the reasons for the penetration of lubricant into the clutch are eliminated (for example, the packing of the front crankshaft seal is worn out, or the oil seal in the gearbox front cover is leaking). If the thickness of the disc of the driven part is within the normal range, both sides of it, the flywheel and the pressure plate are thoroughly washed with white spirit or some other solvent.

- If the bypass channel of the GCC is clogged, the pressure in the clutch hydraulic drive will no longer be relieved. As a result, the friction between the driven plate and the flywheel with the pressure plate will decrease. This, in turn, will lead to a decrease in torque. In this case, it is necessary to disassemble the GCC and rinse its internal parts with clean brake fluid, and pierce the bypass channel with a thin steel wire.

- If the pedal sticks and does not return, excess pressure remains in the RCS. In this situation, the causes of this behavior of the pedal are determined and eliminated.

Clutch leads

If the clutch leads, it becomes very difficult to engage first gear, and when the clutch is disengaged, the car does not stop and continues to move. When the pedal is pressed, the driven disc remains clamped, that is, it does not disconnect from the flywheel and pressure plate. This situation may be due to the following points.

- Too much clearance between the pressure bearing and the heel of the pressure plate. As a result, the clutch does not fully disengage. It is necessary to reduce the length of the RCS rod so that the distance between the bearing and the fifth becomes 4–5 mm.

- Mechanical damage to the driven disk when the clutch overheats in difficult operating conditions of the car. This leads to the appearance of small shaking in the transmission when the end runout exceeds the allowable 0,5 mm. In this case, it is better to replace the clutch with a new one.

- Pulling out rivets on friction linings and, as a result, an increase in the thickness of the driven disk. The drive disk needs to be replaced.

- Wear on the internal splines on the hub of the driven disk. This can lead to jamming on the splines of the gearbox shaft. If wear is detected, smear the splined part with high-quality automotive grease LSTs-15 or replace the parts with new ones.

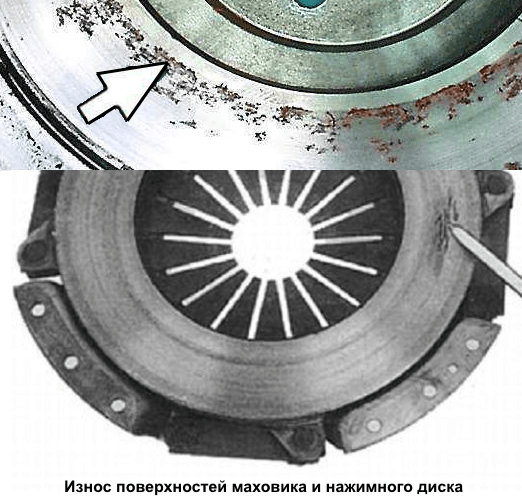

Poor driving and off-road driving will wear out the lining of the driven disc and leave traces of destruction on the flywheel and pressure plate

Poor driving and off-road driving will wear out the lining of the driven disc and leave traces of destruction on the flywheel and pressure plate - The appearance of scratches, scuffs, deep potholes on the surface of the flywheel and pressure plate. This is the result of poor driving and off-road driving with an overheated clutch. Heat weakens the metal of the basket spring plates, which become brittle and break. The clutch must be replaced in this case.

- Accumulation of air in the hydraulic drive. If an air pocket forms, the clutch must be bled.

- Insufficient fluid level in the GCS reservoir due to weak threads or damaged hoses. In such a situation, fittings, plugs should be stretched, rubber tubes should be replaced. After that, it is necessary to remove air from the hydraulic actuator.

- Leakage of the working fluid through leaks at the points of contact of the pistons with the cylinder walls due to wear of the sealing rings in the MCC and RCS. You can correct the situation by replacing the seals with the subsequent removal of air from the system.

- Pollution and blockage of the opening in the lid of the tank for the GCS operating fluid. In this case, pierce this hole with a thin wire and remove air from the hydraulic drive.

Jerks when starting and shifting gears

If the car starts to twitch when starting off and changing gears, the following situations may be the reasons for this:

- The driven disk is jammed on the splines of the gearbox shaft.

- There was oil in the basket.

- The hydraulic drive is misaligned, the RCS piston is wedged.

- Friction linings are heavily worn.

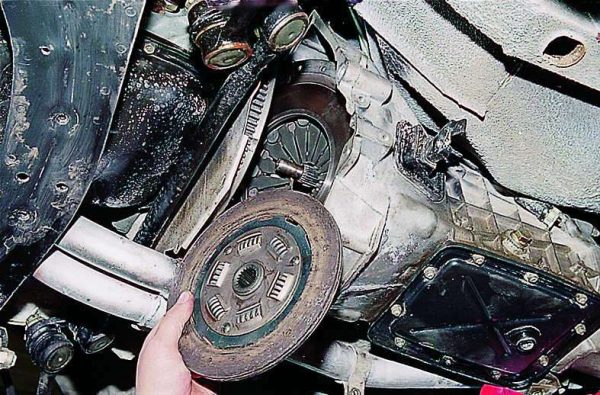

Wear of the friction linings of the driven disk can cause jerks when starting the car and shifting gears

Wear of the friction linings of the driven disk can cause jerks when starting the car and shifting gears - Damaged or warped sectors of the slave disk.

- Due to overheating of the clutch, the working part of the pressure plate and the friction spring controlling it are damaged.

In these cases, the following measures are taken:

- complete clutch replacement

- repair of hydraulic drive devices;

- removal of air from the hydraulic drive by pumping.

Noise when disengaged

Sometimes when you press the clutch pedal, a sharp whistle and rattle is heard. The reason for this may be:

- Damage to the working area or lack of lubrication in the release bearing. The bearing is replaced with a new one.

Lack of lubrication in the release bearing can cause noise when the clutch is disengaged.

Lack of lubrication in the release bearing can cause noise when the clutch is disengaged. - Jamming in the flywheel of the rolling bearing, on which the end of the gearbox shaft rests. The old bearing is pressed out and the new bearing is pressed in.

Noise when clutch engaged

If, when the clutch is engaged (pedal released), rattling, clanging is heard, vibration of the gear lever is felt, this may be due to the following malfunctions.

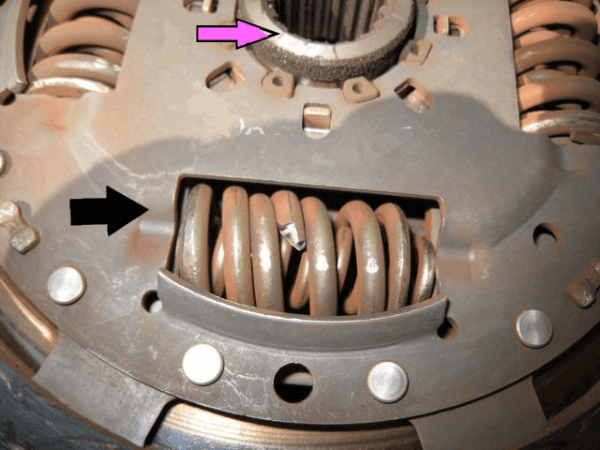

- The torsional vibration damping springs loosened in the sockets of the driven disk hub, became stiff or broke. Defective items are replaced with new ones.

The cause of the noise when the clutch is disengaged may be damage to the damper springs

The cause of the noise when the clutch is disengaged may be damage to the damper springs - Flew, broke, ceasing to work normally, the return spring of the fork. The old spring is securely fixed or a new one is installed.

- The splines in the hub of the driven disk and on the gearbox shaft are very worn out. Worn items are replaced with new ones.

Pedal failure and lack of clutch

If, when pressed, the pedal fails, but then returns to its original position, the clutch stops working for the following reasons:

- Large amounts of air entered the system through loose threaded connections. Fittings are pulled, operating fluid is added, and the hydraulic drive is pumped to remove air.

- There was a leakage of the working fluid through the worn O-rings of the MCC or RCS. Using repair kits for cylinders, protective caps and rubber seals are changed, the working fluid is added to the desired level. After that, the clutch is pumped.

- Bent or broken thrust bearing yoke. The fork is replaced with a new one.

Clutch disengages but pedal does not return to original position

A situation may arise when, when the pedal is pressed, the clutch is disengaged, and the pedal itself does not return to its original position. This may happen in the following cases.

- Air has entered the hydraulic system. Air is removed by pumping.

- The end has flown off, the end has broken off, or the elasticity of the return spring of the pedal and / or the pressure bearing fork has disappeared. The old spring is returned to its place or a new one is installed.

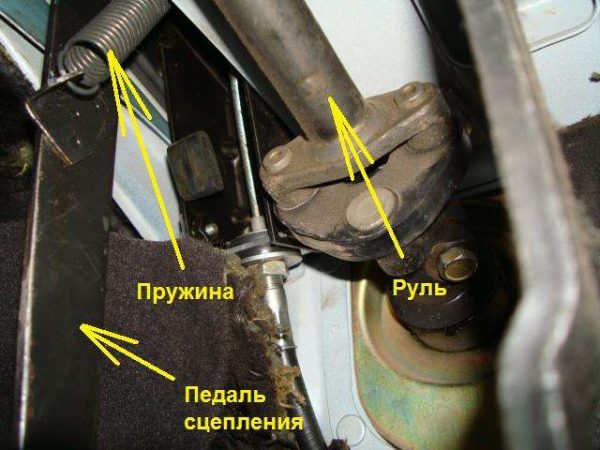

If the clutch pedal does not return to its original position, the reason for this is most often a loose or flown return spring.

If the clutch pedal does not return to its original position, the reason for this is most often a loose or flown return spring.

tight grip

The rigidity of the clutch depends on the condition of the basket damper springs. If they have lost elasticity, the pedal will become very tight. It is necessary to make considerable efforts so that the GCC piston can create pressure that allows the release bearing to press on the tabs and release the driven disk. In this case, the basket must be replaced with a new one.

The initial softness or hardness of the clutch depends on the manufacturer. The owners of the VAZ 2107 speak positively about Starco, Kraft, SACHS, Avto LTD, etc. A tight grip is very inconvenient when driving in traffic jams, when the left leg is constantly in motion.

Clutch disengages at start or end of pedal travel

If the clutch disengages at the beginning of the pedal stroke, it means that there is no free play. The problem is eliminated by reducing the pedal stop offset, measured with a ruler. On the contrary, with increased free play, the clutch is disengaged at the very end of pressing the pedal. In this situation, the length of the RCS rod is adjusted. A large free play indicates a decrease in the thickness of the lining of the driven disk. Often in such cases it is necessary to replace the clutch.

Clutch adjustment VAZ 2107

Clutch adjustment is a mandatory step after troubleshooting or replacement. When dismantling the gearbox, basket, driven disk, the RCS rod is usually unscrewed, therefore, after assembly, the adjustment must be carried out again. This is also necessary if during the operation of the car, for one reason or another, the clutch on / off mechanism is broken. It's pretty easy to make adjustments yourself. This will require a viewing hole, overpass or lift.

Tools and materials

- open-end wrenches for 8, 10, 13 and 17;

- measuring ruler or building corner with divisions;

- passages;

- "Cobra" pliers;

- water repellent WD-40.

The clutch adjustment is carried out after pumping the hydraulic drive.

Pedal free travel adjustment

Pedal free play should be between 0,5 and 2,0 mm. It is regulated from the passenger compartment by changing the reach of the clutch pedal limiter.

The procedure for this is as follows

- With one key by 17, we loosen the lock nut by 2–3 turns, and with the other key, by rotating the head of the limiter, we change its length.

Free travel is regulated by changing the length of the pedal limiter with two keys to 17

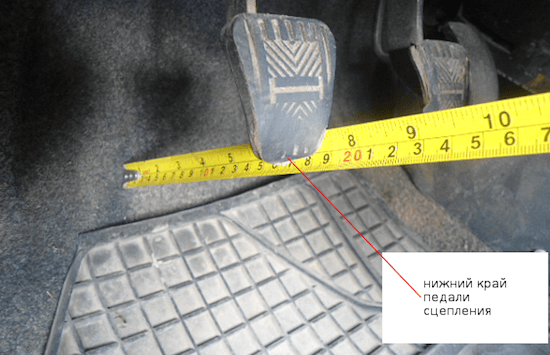

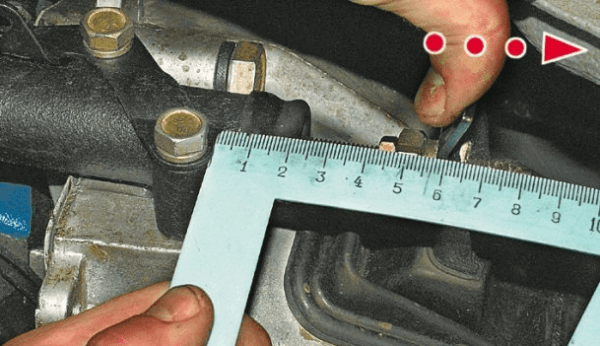

Free travel is regulated by changing the length of the pedal limiter with two keys to 17 - The amount of free play is controlled using a measuring ruler.

Pedal free play is measured using a ruler with graduations.

Pedal free play is measured using a ruler with graduations.

Fork free play adjustment

The free travel of the fork rod is the gap between the release bearing and the fifth diaphragm spring of the pressure plate. Its adjustment is carried out on a viewing hole or lift as follows.

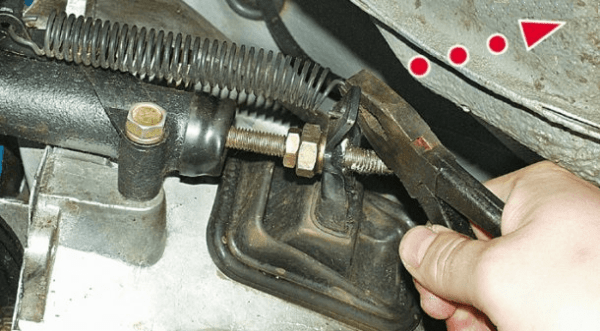

- For the convenience of controlling the free play of the fork, it is necessary to remove the ends of the return spring from the clutch fork and from the plate under the mounting bolts of the working cylinder with pliers.

The ends of the return spring of the clutch fork can be easily removed with pliers

The ends of the return spring of the clutch fork can be easily removed with pliers - With a construction angle or ruler, we measure the amount of free play of the fork - it should be 4–5 mm. If necessary, adjust it by changing the length of the fork stem.

Clutch fork free play should be 4-5 mm

Clutch fork free play should be 4-5 mm

Fork Stem Adjustment

The threaded part of the stem is not protected from dirt and moisture, so the adjusting nut and locknut may not immediately unscrew. It is recommended that after cleaning the stem of dirt, apply WD-40 to the threaded part. Then it is suggested to perform the following steps.

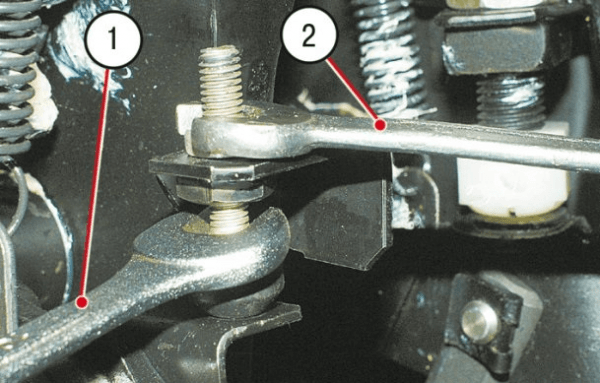

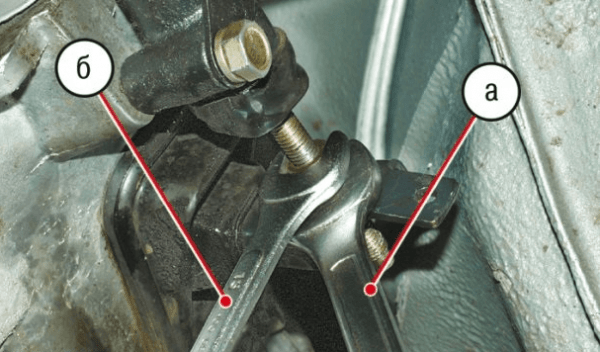

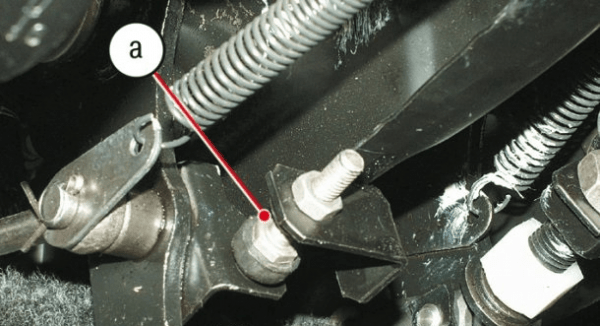

- Holding the adjusting nut with a 17 wrench, loosen the lock nut by 13–2 turns with a 3 wrench.

The adjusting nut is held with a 17 wrench (a), and the lock nut is loosened with a 13 wrench (b)

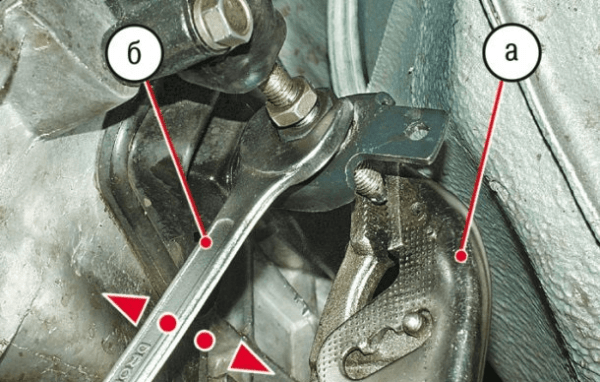

The adjusting nut is held with a 17 wrench (a), and the lock nut is loosened with a 13 wrench (b) - We stop the stem with Cobra pliers and, turning the adjusting nut with a key of 17, set the free play of the stem within 4–5 mm.

When the rod is fixed with the Cobra pliers (b), the adjusting nut rotates with a key of 17 (a)

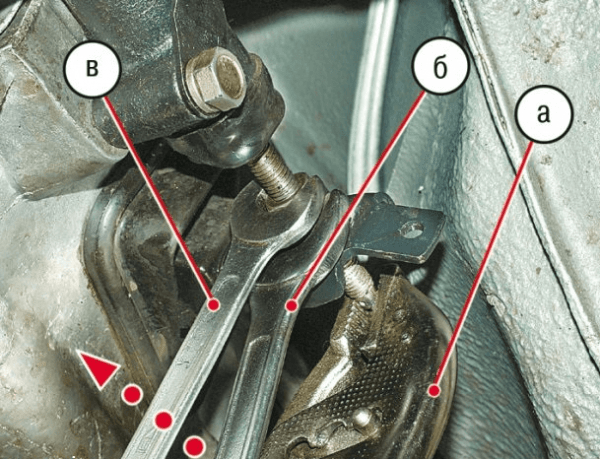

When the rod is fixed with the Cobra pliers (b), the adjusting nut rotates with a key of 17 (a) - We tighten the locknut with a 13 wrench, holding the stem from turning with the Cobra pliers.

After adjustment, when tightening the locknut with a 13 wrench (c), the adjusting nut is held with a 17 wrench (b), and the rod flats with Cobra pliers (a)

After adjustment, when tightening the locknut with a 13 wrench (c), the adjusting nut is held with a 17 wrench (b), and the rod flats with Cobra pliers (a)

After adjustment, it is recommended to check the operation of the clutch. For this you need:

- start and warm up the engine to operating temperature;

- depress the clutch pedal and engage first gear;

- disengage first gear and engage reverse.

A properly adjusted clutch should squeeze out easily, without jamming. Speeds turn on without difficulty and noise. When driving, slipping of the driven disk should not be observed.

Video: DIY clutch adjustment VAZ 2107

A faulty clutch can cause a lot of trouble for the owners of the VAZ 2107. Therefore, experts recommend constantly listening to extraneous noise, knocks, vibrations when shifting gears while driving. Self-adjusting the hydraulic drive is quite simple. This will require only a minimum set of locksmith tools and careful adherence to the advice of professionals.