We independently repair the clutch slave cylinder on the VAZ 2106

Content

Any owner of a VAZ 2106 knows how important good clutch work is. It's simple: the gearbox on the "six" is mechanical, and if something is wrong with the clutch, the car will not budge. And the clutch cylinder delivers the greatest amount of trouble to the owners of the "sixes". On the "sixes" these cylinders have never been reliable. Fortunately, you can change this part yourself. Let's try to figure out how it's done.

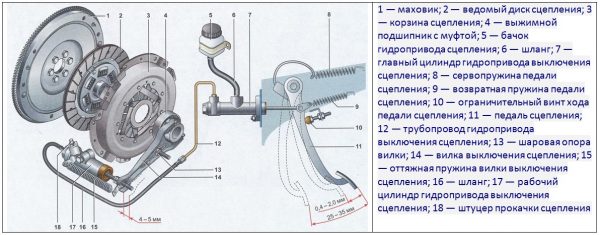

Purpose and operation of the clutch slave cylinder VAZ 2106

In short, the working cylinder in the VAZ 2106 clutch system performs the function of an ordinary converter. It translates the driver's foot force into high brake fluid pressure in the machine's hydraulics.

At the same time, the clutch slave cylinder should not be confused with the main one, because these devices are located in different places on the machine. The main cylinder is located in the cabin, and the working one is attached to the clutch housing with two bolts. Getting to the working cylinder is easy: just open the hood of the car.

Working cylinder device

The clutch slave cylinder consists of the following elements:

- molded case;

- hydraulic piston;

- push rod;

- working spring;

- a pair of annular sealing cuffs;

- washer and retaining ring;

- air valves;

- protective cap.

The clutch slave cylinder has a simple design

The clutch slave cylinder has a simple design

Operating principle

The operation of the cylinder begins at the moment when the car owner presses the clutch pedal connected to the push rod:

- The rod moves and presses on the piston located in the main clutch cylinder. This cylinder contains brake fluid at all times.

- Under the influence of the piston, the fluid pressure increases, it rushes sharply through the hose system to the clutch slave cylinder and begins to put pressure on its rod.

- The rod quickly extends from the cast cylinder body and presses on a special fork, which shifts sharply and presses on the release bearing.

- After that, the clutch discs are separated, which leads to a complete disconnection of the transmission from the engine. The driver at this moment gets the opportunity to turn on the necessary gear.

- When the driver takes his foot off the pedal, everything happens in reverse order. The pressure in all cylinders is sharply reduced, the return spring draws the rod of the working cylinder back into the cast housing.

- The fork is released and goes down.

- Since the clutch discs are no longer in the way, they re-engage, connecting the transmission to the engine. The car then moves on in the new gear.

Signs of breakage

Each owner of a VAZ 2106 should know several important signs that indicate that something is wrong with the clutch cylinder:

- the clutch pedal began to be pressed unusually easily;

- the pedal began to fail (this can be observed both from time to time and constantly);

- the level of brake fluid in the reservoir has dropped significantly;

- there were noticeable smudges of brake fluid on the bottom of the car in the area of \uXNUMXb\uXNUMXbthe gearbox;

If fluid leaks appear on the clutch slave cylinder, then it is time to repair the cylinder

If fluid leaks appear on the clutch slave cylinder, then it is time to repair the cylinder - shifting gears has become more difficult, and moving the gear lever is accompanied by a strong rattle in the box.

Fortunately, the clutch cylinder is easily repairable. Changing the working cylinder on the "sixes" is quite rare, and repair kits for them can be found in almost any auto parts store.

How to remove the clutch slave cylinder

Before proceeding with the repair of the clutch cylinder, it will have to be removed from the car. Here's what you need for this:

- pliers;

- a set of spanners;

- set of socket heads;

- empty container for brake fluid;

- rags.

Sequence of operations

It is most convenient to remove the clutch cylinder in the inspection hole. As an option, a flyover is also suitable. If the driver does not have either one or the other, it will not work to remove the cylinder. The work is done in the following order:

- The return spring of the cylinder is removed manually.

No tools are needed to remove the cylinder return spring

No tools are needed to remove the cylinder return spring - There is a small cotter pin on the end of the pusher. It is gently grasped with pliers and pulled out.

The cylinder pin can be easily removed with small pliers

The cylinder pin can be easily removed with small pliers - Now loosen the locknut on the slave cylinder hose. This is done using a 17 mm open-end wrench.

The locknut on the cylinder hose is loosened with a 17 mm open end wrench.

The locknut on the cylinder hose is loosened with a 17 mm open end wrench. - The cylinder itself is attached to the crankcase with two 14 mm bolts. They are unscrewed with a socket head.

Cylinder fasteners are unscrewed with a 14 mm socket head with a long collar

Cylinder fasteners are unscrewed with a 14 mm socket head with a long collar - To remove the cylinder, it is necessary to hold the hose end by the nut with a 17 mm wrench. With the second hand, the cylinder rotates and disconnects from the hose.

Video: removing the clutch cylinder on the "classic"

How to repair clutch slave cylinder

Before describing the cylinder repair process, a few words should be said about repair kits. The vast majority of problems in the "six" cylinders are associated with a violation of tightness. And this happens due to wear of the sealing cuffs of the cylinder. Cuffs can be purchased individually or as a set.

Experienced car owners prefer the second option. They take a kit, disassemble the cylinder and change all the seals in it, regardless of their degree of wear. This simple measure greatly increases the service life of the slave cylinder and ensures that there are no brake fluid leaks for a long time. Repair kit for the clutch slave cylinder "six" consists of a protective cap and three sealing cuffs. Its catalog number is 2101-16-025-16, and it costs about 100 rubles.

For repairs, you will need the following tools:

- pliers;

- open-end wrench 8 mm;

- rags;

- flat screwdriver;

- vise.

Repair sequence

It will be extremely difficult to perform all the operations listed below without normal locksmith vise. If they are, then you need to do the following:

- The clutch cylinder, removed from the car, is clamped in a vise so that the air valve is outside.

- Using an 8 mm open-end wrench, the air valve is unscrewed and inspected for wear and mechanical damage. If even minor scratches or abrasions are found on the valve, it should be replaced.

- After unscrewing the valve, the vice is loosened, the cylinder is set vertically and again clamped with a vice. The protective cap must be outside. This cap is carefully pry from the bottom with a flat screwdriver and pulled off the stem.

- Now you can remove the pusher itself, since nothing else holds it.

To extract the pusher, the cylinder will have to be clamped vertically in a vice

To extract the pusher, the cylinder will have to be clamped vertically in a vice - After removing the pusher, the cylinder is again clamped horizontally in a vice. The piston located in the cylinder is gently pushed out of it with the help of the same screwdriver.

- Now the lock ring is removed from the piston, under which there is a return spring with a washer (you need to remove the lock ring very carefully, as it often jumps off and flies away). Following the ring, the washer is removed, and then the return spring.

The retaining ring must be removed very carefully.

The retaining ring must be removed very carefully. - Only two cuffs remained on the piston: front and back. They take turns prying off with a thin flat screwdriver and removed from the piston (some drivers prefer to use a thin awl to pry off the cuffs).

To remove the cuffs from the piston of the cylinder, you should pry them with an awl or a screwdriver

To remove the cuffs from the piston of the cylinder, you should pry them with an awl or a screwdriver - The surface of the piston, released from the cuffs, is carefully inspected for scratches, cracks and other mechanical damage. If dents, scuffs, cracks and other defects are found, the piston will have to be replaced. The same rule applies to the inner surface of the cylinder body: if defects are found there, the best option is to purchase a new cylinder, since such damage cannot be repaired.

- In place of the removed cuffs, new ones are installed from the repair kit. After that, the cylinder is reassembled with the installation of a new protective cap from the same repair kit.

Video: we independently disassemble the “classic” clutch cylinder

Watch this video on YouTube

Bleeding the VAZ 2106 clutch with the help of a partner

Replacing the cylinder or any other manipulations with the clutch will inevitably lead to depressurization of the hydraulic drive and to the ingress of air into the clutch hoses. To normalize the operation of the clutch, this air will have to be removed by pumping. Here is what is required for this:

- 0,5 liters of new brake fluid;

- a piece of rubber hose 30 cm long;

- open-end wrench 8 mm;

- empty container for brake fluid.

Sequence of work

For normal pumping, you will have to use the help of a partner. It's simply impossible to do everything alone.

- When the clutch slave cylinder is repaired and installed in its original place, brake fluid is added to the reservoir. Its level should reach the upper mark located near the neck of the tank.

The fluid in the clutch reservoir must be topped up to the mark next to the neck

The fluid in the clutch reservoir must be topped up to the mark next to the neck - The clutch cylinder has an air valve with a fitting. One end of the hose is put on the fitting. The second one is lowered into an empty container (an ordinary plastic bottle is best for this purpose).

The other end of the hose attached to the fitting is lowered into a plastic bottle

The other end of the hose attached to the fitting is lowered into a plastic bottle - After that, the partner must press the clutch pedal six times. After the sixth press, he should keep the pedal fully sunk into the floor.

- Unscrew the air valve fitting two or three turns using an 8 mm open-end wrench. After unscrewing, a characteristic hiss will be heard and bubbling brake fluid will begin to come out into the container. It is necessary to wait until the bubbles stop appearing, and tighten the fitting.

- Now again we ask the partner to press the clutch pedal six times, unscrew the fitting again and bleed the air again. The procedure is repeated until the liquid pouring from the fitting stops bubbling. If this happens, the pumping can be considered completed. It remains only to add fresh brake fluid to the reservoir.

How to adjust the clutch rod on a VAZ 2106

After completing the pumping of the working cylinder, it is imperative to adjust the clutch rod. This will require:

- set of open-end wrenches;

- medium-sized caliper;

- pliers.

Adjustment sequence

Before proceeding with the adjustment, you should look at the operating instructions for the machine.. It is there that you can clarify all the necessary tolerances for the rod and clutch pedal.

- First, the clutch pedal play (aka free play) is measured. It is most convenient to measure it with a caliper. Normally, it is 1-2 mm.

- If the free play exceeds two millimeters, then using a 10 mm open-end wrench, the nut located on the free play limiter is unscrewed. After that, you can turn the limiter itself and set the required pedal free play.

Clutch pedal free play adjustable

Clutch pedal free play adjustable - After the restrictor stud is properly installed, its nut is screwed into place.

- Now you need to measure the full amplitude of the pedal. It should be in the range from 24 to 34 mm. If the amplitude does not fit within these limits, you should re-adjust the stem, and then repeat the measurements.

Video: how to adjust the clutch drive

Watch this video on YouTube

Checking and replacing the hose on the clutch cylinder

The hose on the clutch slave cylinder is an extremely critical part exposed to high brake fluid pressure. Therefore, the car owner should monitor its condition especially carefully.

Here are signs that indicate that the hose needs to be changed urgently:

- cracks and other mechanical damages visible to the naked eye appeared on the hose;

- the hose looks intact, but smudges of brake fluid are visible on it (this means that it is still damaged and microcracks have appeared on it that the driver simply cannot see);

- the threads on the hose ends are partially or completely stripped.

If you notice any of the above, the hose should be replaced immediately. It is better to install standard VAZ clutch hoses, their catalog number is 2101-16-025-90, and the cost is about 80 rubles.

Hose replacement sequence

Before starting work, stock up on an empty plastic bottle and two open-end wrenches: 17 and 14 mm.

- The car is driven into the pit and fixed with wheel chocks. Open the hood and find the place where the slave cylinder hose is screwed to the clutch hydraulic tube.

- The main hose nut is held firmly with a 17 mm wrench, and the fitting on the hydraulic tube is unscrewed with a second wrench - 14 mm. After unscrewing the fitting, brake fluid will flow out of it. Therefore, in the inspection hole there should be a container for collecting it (the best option would be a small basin).

- The second end of the hose is unscrewed from the body of the working cylinder with the same 17 mm key. There is a thin sealing ring in the cylinder under the hose nut, which is very often lost when the hose is removed.. This ring should also be changed (as a rule, new seals come with new clutch hoses).

- A new hose is installed in place of the old one, after which a new portion of brake fluid is added to the hydraulic system.

So, even a novice driver can change the working cylinder on the "six". All that needs to be done for this is to carefully prepare the necessary tools and strictly follow the above recommendations.