Do-it-yourself soundproofing VAZ 2107: types of materials and application technology

The silence and comfort of any car depends on the preparation of the body and its elements for operation in different road conditions. Many owners of the VAZ 2107 have to modify the car on their own by applying special materials to reduce the level of noise and vibration in the cabin, which are most evident on poor roads. Using high-quality materials and adhering to the application technology, you can improve the sound insulation of the "seven".

Noise isolation VAZ 2107

The factory sound insulation of the VAZ 2107 leaves much to be desired, which also applies to other cars of the domestic auto industry. Noises in the cabin interfere not only with normal conversation, listening to music, but also increase the irritability of the driver. To eliminate this drawback of the "seven" and improve comfort, the car needs to be finalized.

What is soundproofing for?

For those who do not spend much time in the car, there may not be a need to spend on retrofitting. If there is a constant rattle in the cabin, which is especially annoying on long trips, then it will be quite useful to improve the soundproofing characteristics. Main noise and vibration are transmitted from the power unit to the body and its elements. If there are any loose parts and there is no gasket between them, then the vibrations will enter into resonance and spread throughout the cabin.

On our roads, the problem of noise and vibration manifests itself most clearly. Take at least gravel, blows from which through the wheel arches reach the inside of the vehicle. A quiet and comfortable interior is inherent in expensive cars, and even then not always. The fact is that manufacturers pay more attention to dynamic performance, reducing the mass of the body, and a potential client is ready to pay money for this. As for comfort, it is relegated to the background, and the car owner has to take care of improving the soundproofing properties.

Long pastime behind the wheel in a noisy cabin negatively affects the human nervous system: the body is subjected to nervous overload, hearing deteriorates, and rapid fatigue occurs. In addition, headaches are possible and, even worse, an increase and jumps in blood pressure. From the foregoing, the following conclusion follows - being in a noisy salon is harmful to health. Without silence inside the car, it will also not be possible to listen to high-quality music and talk with passengers. Noise isolation, in addition to everything, is a good interior insulation and a good tool for combating corrosion, which allows you to increase the life of the car.

What is soundproofing

Today, a wide range of special soundproofing materials of different types and manufacturers is offered. Which sound insulator to give preference depends on the tasks. All available materials have a wide classification and are divided into types, each of which is best suited for application to a specific area of \uXNUMXb\uXNUMXbthe car. The final result will depend on the correct choice and combination of materials with each other.

Noise and sound insulation is most common for reducing and eliminating noise in the vehicle interior. Noise isolation is of the following types:

- vibration isolation;

- soundproofing;

- noise absorbers;

- liquid soundproofing materials;

- anti-creak.

In general, materials are divided into sheet and liquid, and which one to choose remains to be figured out.

Sheet

Sheet noise and vibration isolation is one of the traditional and most common materials. Based on the name, the products are sheets of different dimensions, thickness and weight. Vibration isolation is the first thing to start with increasing the level of comfort in the VAZ 2107 cabin. There are many materials that differ not only in composition, but also in the level of safety and operating temperature indicators. Vibromaterials used to reduce vibrations of car body elements contain foamed rubber or bitumen. As a result of friction, losses occur in them. The main characteristics of a good material are the coefficient of mechanical losses and the dynamic modulus of elasticity. The higher the coefficient, the thicker and heavier the material, and the more efficiently vibrations will be absorbed.

The most common materials used for car vibration isolation are products from STP, which is recommended by many experts in this field. The products of this manufacturer are characterized by relatively low cost and quality characteristics. The following are distinguished from vibromaterials: Bimast Super, Bimast Standard, Vibroplast Silver, Vibroplast Gold, Vizomat PB-2, Vizomat MP.

Noise isolation of cars is carried out using two types of materials:

- on a natural or synthetic fiber-structural basis;

- on a synthetic gas-filled plastic base.

The first version of the sound-absorbing material is used as a factory coating: it is based on felt with a bituminous layer on top. However, soundproofing materials made of synthetic felt can also be purchased. There is an opinion that the second option is characterized by higher efficiency, but at the same time such a "shumka" absorbs moisture. As a result, the fabric decomposes over time, the metal rots. Noise insulation based on plastic also has such a disadvantage, but at the same time the material itself does not become unusable, since the front film reflects both sound waves and moisture. As a rule, lavsan film is used as a material. For independent soundproofing, materials such as Accent, Isoton (V, LM), Bitoplast, Biplast are usually used.

In addition to noise and vibration isolation materials, there are also so-called anti-creaks. They are designed to eliminate squeaks of facing elements, plastic panels. Some motorists use any soft material as an anti-creak, for example, foam rubber, Carpet, window seal. However, the gasket must be durable, resistant to abrasion, withstand environmental influences, which the listed materials cannot boast of. To prevent squeaks, it is recommended to use the following materials: Bitoplast Gold 5mm, Biplast 5mm, Madeleine.

On sale you can find products for sound and heat insulation. It is endowed with such positive qualities as an affordable price, resistance to moisture, heat retention. However, if we adhere to the opinion of experts, then it is not entirely correct to use such sound insulators as noise-absorbing materials for a car, due to their low efficiency. To get a result from their application, it is necessary to apply the material to the floor in one piece without joints, which is impossible due to the design features of the body.

It should also be taken into account that when laying the material on the vibration isolation layer, its effectiveness is reduced due to wave reflection. If you plan to use sound and heat insulating materials in your VAZ 2107, then their use is allowed only after sound insulation. These materials include Splen, which perfectly retains heat in the car, which is a definite plus when operating a vehicle in winter.

liquid

Recently, liquid sound insulation has become more and more popular among motorists, including owners of the VAZ 2107. The composition is designed to absorb noise from the wheel arches and the bottom of the car. This means that when crushed stone and other small objects from which noise occurs, these sounds will not be heard in the cabin. The basis in such material is liquid rubber, which has its advantages and disadvantages. Consider first the positive qualities of the substance:

- prevents road noise;

- improves road acoustics;

- protects the bottom and wheel arches from the formation of rust;

- protects against scratches and moisture;

- has high wear resistance, unlike sheet materials.

The liquid composition has almost no effect on the handling of the car. This is due to the fact that the material slightly affects the increase in weight (no more than 20 kg per car), which cannot be said about sound insulation in sheets, which gives an increase in weight up to 150 kg.

Of the shortcomings of liquid soundproofing compositions, there are:

- long drying time (about three days);

- higher cost compared to sheet materials;

- in terms of vibration damping, liquid sound insulation is inferior to sheet sound insulation.

Before applying the liquid composition to the body, the surface is prepared with car shampoo and subsequent degreasing. In addition, it is recommended to pre-treat the surface layer with fine sandpaper and apply a layer of primer, and then let it dry. It remains to cover the bottom and wheel arches with material. Of the most common manufacturers of liquid sound insulation, Noxudol 3100, Dinitrol 479, Noise Liquidator can be distinguished.

How to apply soundproofing materials

Noise isolation of the car should be carried out exclusively by products designed for this. The use of building materials, for example, is inappropriate in this case, since you can not only not get the expected effect, but also harm. Some car owners of "sevens" and other classic cars use polyurethane foam, which fills all possible cavities in the body. However, this material absorbs moisture quite strongly, thereby contributing to the appearance and spread of corrosion. As a result of rotting metal, it is necessary to change the body elements much earlier than it could be required.

Equally important is the order in which the soundproofing layers will be located. If the technology is violated, it will not be possible to achieve the pursued goal, regardless of what materials are used. You need to apply them in the following order:

- The vibration isolator is glued to a metal surface.

- Lay a sound-reflecting and sound-absorbing layer. The first material is used to process wheel arches and the engine compartment, the second is applied inside the cabin.

- Soundproofing is used as the third layer, which is placed under the dashboard and skin elements.

- The last layer is a finishing one, giving a finished look to the work.

Noise isolation of individual body parts VAZ 2107

Noise isolation of the VAZ 2107 is preferably carried out in a room protected from precipitation, for example, a garage. To work, you will need the following list of materials and tools:

- rags;

- solvent;

- a set of screwdrivers and keys;

- building hair dryer;

- roller for rolling sheets of sound insulation;

- cotton mittens;

- cardboard for patterns;

- spray gun for applying liquid sound insulation on the bottom;

- soundproofing materials.

In addition to the materials listed, you will need tools for preparing the body: solvents, detergents and a large amount of water. One of the pressing questions of the owners of the seventh model Zhiguli, who have decided to increase the comfort of their car, is how much material is needed for soundproofing. For pasting the body of the VAZ 2107, you will need about 15–20 sheets of Shumka. More accurate figures depend on the dimensions of a particular material.

Underbody and wheel arches

Work on soundproofing a car consists of a set of procedures that must be started from the outside. First of all, wheel arches and the bottom of the vehicle are subject to processing. Work is carried out in the following sequence:

- Perform a thorough cleaning and washing of the underbody.

- If there is a compressor, they blow the cavities with air or wait for natural drying.

- Prepare the surface by degreasing with solvents. The room must be ventilated during operation.

- When the surfaces are dry, a uniform layer of sound insulation is applied to them with a brush or spray gun.

It is important to monitor the application of the material so that there are no gaps. After the sound insulation has dried, you can install lockers and fender liner in the wheel arches.

Video: liquid soundproofing of wheel arches on the example of Toyota Camry

Salon

Before proceeding with the soundproofing of the VAZ 2107 cabin, it is necessary to make sure that all components and mechanisms from which extraneous noise can be heard are in perfect operation. Work must be carried out in such a way that the materials used do not block the mounting holes. Soundproofing the cabin is performed in the following sequence:

- Dismantle the seats and dashboard.

To soundproof the cabin, you will need to dismantle the dashboard and seats

To soundproof the cabin, you will need to dismantle the dashboard and seats - Remove ceiling and floor coverings.

- They clean the surface of contamination, clean the areas where there is corrosion, and treat them with a primer, after which they degrease with a solvent.

Before applying soundproofing, the surface is cleaned of dirt and degreased.

Before applying soundproofing, the surface is cleaned of dirt and degreased. - Vibroplast is glued onto the roof surface, and then a layer of Accent.

The inner surface of the roof is pasted over with vibration, and after soundproofing

The inner surface of the roof is pasted over with vibration, and after soundproofing - Vibroplast is applied to the arches inside the cabin, and two layers of Accent are applied on top of it.

Vibroplast is applied to the inner surface of the arches, and on top of it are two layers of Accent

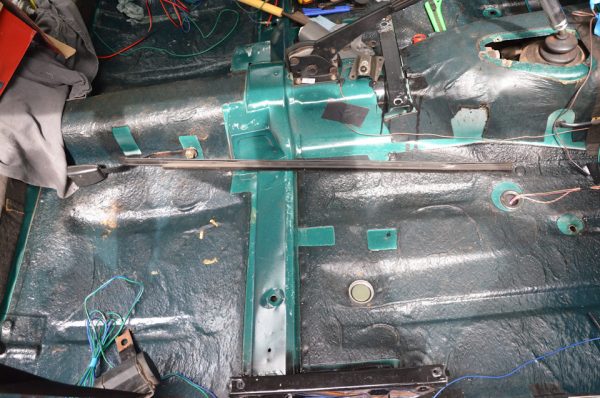

Vibroplast is applied to the inner surface of the arches, and on top of it are two layers of Accent - Bimast Super is laid on the floor, then Accent.

First, a layer of vibration isolation is applied to the floor, and soundproofing material is applied on top of it.

First, a layer of vibration isolation is applied to the floor, and soundproofing material is applied on top of it. - The inside of the dashboard is pasted over with Accent.

Soundproofing material is applied to the inner surface of the front panel

Soundproofing material is applied to the inner surface of the front panel - The partition of the body under the front panel is pasted over with Vibroplast.

- To prevent squeaks, Madeleine is glued in places where the dashboard fits to the body.

It is more convenient to carry out soundproofing of the roof with an assistant who warms up the material and holds it in the process of rolling.

Video: ceiling soundproofing VAZ 2107

Watch this video on YouTube

Doors

The doors of the "seven" are also subject to soundproofing, which improves the sound from the built-in dynamic heads, eliminating resonance, and prevents external noise from entering the cabin. To do this, the handles and upholstery are first removed from the doors, the surface is cleaned and degreased. Isolation is carried out in the following order:

- Vibroplast is applied to the door panel.

A layer of Vibroplast or similar material is applied to the inner surface of the doors.

A layer of Vibroplast or similar material is applied to the inner surface of the doors. - The second layer is glued Accent.

A soundproofing layer is applied on top of the vibration isolation

A soundproofing layer is applied on top of the vibration isolation - The door lock rods are wrapped with Madeleine, which will eliminate squeaks and rattles.

- Vibroplast is applied to the outer surface of the doors.

Vibroplast is applied to the outer surface of the doors, and then a layer of Accent or similar material

Vibroplast is applied to the outer surface of the doors, and then a layer of Accent or similar material - Technological openings are sealed with Bitoplast.

- Accent is applied to the inside of the door skin, which will ensure a better fit of the card to the door, and will also have a positive effect on sound absorption.

Accent is applied to the salon side of the door, which will improve the fit of the skin

Accent is applied to the salon side of the door, which will improve the fit of the skin

Motor shield and trunk

There is an opinion that soundproofing the engine compartment is necessary only in order to reduce the level of noise emitted by a running engine into the environment. Actually it is not. The application of noise-absorbing materials on the hood and engine shield has several goals:

- reduce metal vibration;

- muffle the sound of the motor penetrating into the cabin;

- improve thermal insulation and prevent the motor from cooling down quickly in winter.

The luggage compartment should be soundproofed for the following reasons:

- the sound of the subwoofer improves, if there is one or it is planned to be installed;

- the sounds penetrating into the cabin from the outside are muffled;

- vibrations are reduced during the movement of the machine, as well as during the operation of acoustics.

Soundproofing the space under the hood begins with pasting the engine shield. To Vibroplast before laying was more pliable, it is heated with a building hair dryer. After gluing the material, they pass over the surface with a roller to get rid of air bubbles, which not only worsen the properties of the sound insulator, but can also lead to corrosion. Splen is applied over Vibroplast. The lid of the luggage compartment and the hood are pasted over with the same materials.

The only difference is that Vibroplast is applied between the stiffeners. The wheel arches of the trunk must be covered with another layer of sound insulation. Upon completion of all work, the cabin is assembled.

In the process of protecting the car from noise and vibration, it is important not to overdo it with the amount of material, since the vibration isolation is quite heavy, which will affect the overall weight of the car. There is nothing complicated in independent soundproofing: you need to select and prepare the necessary materials and tools and follow the step-by-step recommendations.