Symptoms of dual-mass flywheel problems

Content

Briefly about the damper flywheel

The role of the flywheel is to reduce uneven rotation. It retains the necessary kinetic energy during operation. The dual-mass flywheel consists of two discs that are connected by durable springs. They serve to absorb vibrations.

The standard dual-mass flywheel consists of a primary and secondary flywheel. Another function of the damper flywheel is to reduce vibrations during the crankshaft torque of the vehicle.

There are two types of flywheels:

- damping (two-mass);

- one-piece (single-mass).

Two independent flywheel disks are connected by a spring (damping system) and attached to each other using a sliding bearing or a deep groove ball bearing that helps them rotate.

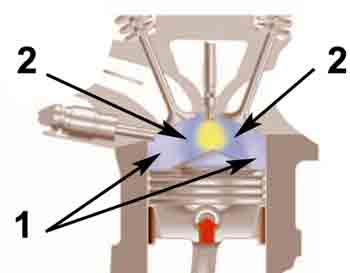

The main flywheel has a gear that connects to the engine and bolts to the crankshaft. This and the main cover form a cavity, which is a spring channel.

The damper system is made of arched springs in the guide bushings in the spring channel. The engine torque is transmitted through the flange, which is mounted together with the auxiliary flywheel. To prevent overheating, the dual-mass flywheel has openings for air intake.

A flywheel of this type has several advantages for the functioning of the car. It also provides greater driving comfort. For this reason, it is worth checking it periodically to fix problems in a timely manner.

Ignoring damage to the flywheel damper is undesirable, as over time this can lead to serious problems with other parts of the car that come in contact with its surface.

Advantages and disadvantages of the damper flywheel

Unlike a single-mass flywheel, the dual-mass counterpart not only eliminates vibration, but also prevents wear on the gearbox and timing components, as it absorbs the load.

It also makes gear changes easier than with a single-mass flywheel and reduces noise. Its guide bushings stabilize the assembly, and the grease located in the spring channel prevents friction between the arc spring and the guide bush.

Other advantages are that it saves fuel at low engine speeds and protects the drive from overheating. This type of flywheel can be installed on both automatic and manual gearboxes. Shifting gears that are too frequent shortens the flywheel’s life as it increases the load on the flywheel, so a standard part sometimes fails.

Flywheels of cars that drive off-road for long distances have a relatively longer service life and require less repair than cars that are mainly used for city driving.

The only drawbacks of the damping flywheel is that it wears out faster and requires earlier repair. It is also more expensive than a hard flywheel. But this investment is certainly worth it and pay off over time.

Common Damper Flywheel Problems and Helpful Repair Tips

The damper flywheel is a modification that most often fails and needs to be repaired. When the vehicle has high mileage, the damping flywheel, which functions in contact with the friction disc, may show signs of wear on the running surface.

If dents, scratches or stains are found, it means that the flywheel has overheated. When we find such damage, we must take urgent repair measures. In this case, it is important to remember that they cannot be sanded without observing the permissible limits established by the vehicle manufacturer. Avoid mechanical treatment of the friction surface of the damper flywheel.

Another thing we can check to prevent more serious damage in the future is to check that the gap between the speed sensors and the flywheel signal pins is correctly set.

When installing a dual-mass flywheel, it is always recommended to use new mounting bolts because of their ability to deform. Worn parts must not be reused. Before installing a new flywheel, the contact surface of the clutch pressure and friction discs must be cleaned with a degreasing agent.

How to determine if the flywheel is damaged?

When the springs inside the flywheel wear out, this forms a gap between the two discs. The presence of play is a sure sign that the flywheel is worn out and needs to be replaced. A damaged flywheel usually makes a rattling sound, most often in cold weather, for example, when we start the engine in the morning. This rattling noise usually lasts about 5-10 minutes and then stops.

In winter, the sound of a damaged flywheel is heard most clearly. We should not wait for an increase in rattling or vibration, as this will only worsen the situation.

Some signs of a damaged flywheel damper

1st sign: squeak

When the car starts in 1st gear, a squeak occurs. This problem occurs mainly at winter temperatures and in cases where the engine cannot warm up sufficiently.

The main reason for this is that when the flywheel springs are already worn out, they cannot properly absorb the vibration of the engine. And these vibrations are felt most when we switch to 1st gear.

2nd sign: slippage

When we abruptly begin to accelerate the car, slippage is felt. It may also mean that the friction clutch disc is damaged. Its wear leads to a lack of traction, which only leads to its slipping on the surface of the flywheel. However, a slippage in the clutch, which also causes a specific knock, may also cause slippage.

Before we decide to buy a new flywheel or any other auto parts, it is better to consult an authorized service center where experienced consultants can determine exactly what the problem is and give us professional advice on which brands of spare parts are more suitable.

Questions and answers:

What happens if the dual-mass flywheel breaks down? Basically, its malfunction will immediately manifest itself as a lack of damping of torsional vibrations coming from the crankshaft to the gearbox shaft.

What happens if the flywheel is not replaced in time? A dual-mass flywheel is an integral part, therefore, its breakdown will lead to fatal consequences for the car, especially if the flywheel disintegrates while driving.

How does a dual-mass flywheel fail? First of all, in such a flywheel, the damper elements fail. At the same time, there is a grinding and squeaking sound, especially during starting and stopping the motor.

5 comments

Jim

Very helpful answers my question as to why gearchanges are not smooth at the moment on my Transit

Massoud

Thank you for the information.

When I start my car and the engine is cold, a sound comes out from the flywheel and clutch area. After ten minutes have passed, the sound stops and the sound is not very strong. The question is what does the flywheel have to do with the engine temperature and if there are damaged springs why does the sound not continue? Thank you very much for the answer

Jan

And a tap in the flywheel doesn't say it's gone. I have a Peugeot 207 1.6hdi there is a new lux in it that ticks all the way when new when you give something gas and loose and a few taps to and then away

Henk

Jan I also have and 207 hdi 1.6 Lux is also in mine, which is also ticking from new if you give it gas and release, it also ticks exactly like yours, this will be in the flywheel brand?

Jan

The