Common Rail system in diesel engines - checking the principle of operation

Content

- Diesel injection system - history of development

- Diesel engine with injection pump - the principle of operation of the system

- Benefits of using a diesel engine

- The Common Rail system - how does it differ from its predecessors?

- Common Rail - what does it give the engine?

- Common rail engine and fuel injection timing

- History of common rail engines

- Common rail in truck engines

- Direct Injection - Common Rail Diesel and Fuel Quality

- The Common Rail system in the engine and its disadvantages

- Common Rail Diesel Fuel and Maintenance Costs

- How long do common rail injectors last?

- How to find out damage to common rail injectors?

In 1936, a diesel engine appeared for the first time on a Mercedes-Benz production car. Now modern diesel engines have a completely different design, and Common Rail is responsible for their work. What's this? This is a way of supplying the drive with fuel. Unlike gasoline engines, diesel engines have long been based on the direct injection of diesel fuel into the combustion chamber. The Common Rail is one of the latest designs and a milestone in the development of compression ignition engines. How it works? Read our article!

Diesel injection system - history of development

In the early compression ignition units, fuel was injected into the cylinder along with air. Air compressors were responsible for this. Over time, more and more accurate and efficient high-pressure fuel pumps were developed, and prechambers with indirect injection were used for the production of automobile engines. Further solutions:

- spring nozzles;

- injector pump;

- piezo injectors;

- electromagnetic nozzles;

- Battery fuel system.

In the text, of course, we will talk about the last of them, i.e. about the Common Rail system.

Diesel engine with injection pump - the principle of operation of the system

At the outset, it should be noted that ignition in diesel engines occurs under high pressure and does not require an external spark, as is the case with gasoline engines. An extremely high compression ratio is a prerequisite, and the fuel must be supplied under enormous pressure. The injection pump can be divided into sections to supply fuel to a specific cylinder. Using a distributor piston, he generated a dose distributed in the head through separate fuel lines.

Benefits of using a diesel engine

Why do users love diesel units? First of all, these engines provide a very good work culture with low fuel consumption (compared to spark ignition units). They may not reach such impressive horsepower, but they generate high torque. It starts already at low engine speeds, so it is possible to keep the units in these lower parts of the rev range. Common rail engines and other types of diesel injection are also extremely durable.

The Common Rail system - how does it differ from its predecessors?

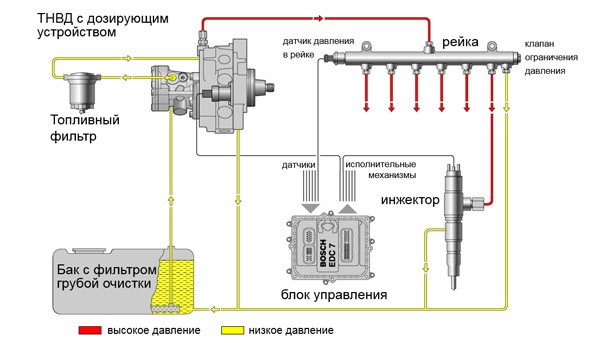

In the diesel engines used so far, the injectors worked under the control of the injection pump. Some exceptions were pump injectors, which are combined with pistons that are responsible for creating fuel pressure. Common rail injection works differently and uses a rail called a rail. In it, fuel accumulates under very high pressure (over 2000 bar), and injection occurs after receiving an electrical signal applied to the nozzle.

Common Rail - what does it give the engine?

What effect does such a cycle of fuel injection into the combustion chamber have on the drive? The benefit comes from the very increase in fuel pressure that is injected into the cylinder. Getting almost 2000 bar at the nozzle allows you to create an almost perfect fuel mist that mixes perfectly with air. The electronic control of the needle lift moment also enables the use of injection phases. what are they?

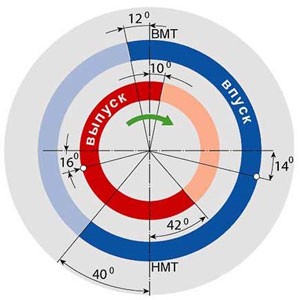

Common rail engine and fuel injection timing

Modern common rail engines have at least 5 injection stages. In the most advanced engines, there are 8 of them. What are the consequences of this method of fuel supply? The division of the injection into phases softens the operation of the engine and eliminates the characteristic knock. This also enables a more thorough combustion of the mixture, resulting in greater engine efficiency. It also produces fewer NOx substances, which have been eliminated in diesel engines in various ways over the years.

History of common rail engines

The first common rail injection engines were introduced in passenger cars by Fiat. These were JTD marked units that met Euro 3 emission standards. Although it was an innovative engine, it was very well engineered and proved to be reliable. Today, the 1.9 JTD and 2.4 JTD units are highly valued in the secondary market, even though more than 24 years have passed since the release of the first Common Rail Fiat.

Common rail in truck engines

However, Fiat was not the first manufacturer in the world to launch a common rail vehicle. This car was produced by the Hino brand. This is a Japanese company that manufactures trucks and is subordinate to Toyota. In her Ranger model, a 7,7-liter (!) Unit was installed, which, thanks to modern injection, produced 284 hp. The Japanese introduced this truck in 1995 and beat Fiat by 2 years.

Direct Injection - Common Rail Diesel and Fuel Quality

It is here that one of the disadvantages of this type of design manifests itself. This is an exceptionally high sensitivity of the injectors to the quality of the fuel. Even the smallest impurities that the fuel filter cannot catch can clog the holes. And these are microscopic dimensions, because the pressure of the fuel does not force the design of perforations of a larger size. Therefore, each owner car with Common Rail, you need to take care of refueling diesel fuel at proven stations. You also need to be careful with high fuel sulfation, which has a detrimental effect on injectors.

The Common Rail system in the engine and its disadvantages

One of the disadvantages that we have already mentioned is that this way of supplying fuel to the engine forces you to buy the highest quality fuel. On power units with other fuel systems, a fuel filter change is usually required every 2nd or 3rd engine oil change. With Common Rail, you can't wait that long. Oil maintenance is more expensive, because almost every time you have to reach for a new filter.

Common Rail Diesel Fuel and Maintenance Costs

This is another reason why you should take care of the quality of the fuel in these diesels. Regeneration, including cleaning of common rail injectors, costs about 10 euros per piece. If a replacement is necessary, you will unfortunately be in for a very unpleasant surprise. The cost of one copy can even exceed 100 euros. Of course, it depends on the specific car model. In the worst case, you will have to pay for 4 pieces. For V6 or V8 engines, the amount increases accordingly.

How long do common rail injectors last?

This question is of great interest to buyers of cars from the secondary market. Nothing unusual. After all, they want to buy a car in the near future that will not require injection regeneration. Manufacturers suggest that Common Rail injectors will cover about 200-250 thousand kilometers without breakdowns. Of course, these are estimates and you can't stick to them. For many cars, this mileage has long been passed, and there are still no obvious signs of breakdown. In other cars, it happens that after 100 XNUMX or a little more mileage, you have to change one nozzle or even the entire set.

How to find out damage to common rail injectors?

It's not as easy as with older unit types. New diesels have many systems that improve the quality of exhaust gases (including DPF). This system prevents most of the exhaust gases from escaping to the outside. Thus, a leaky common rail injector can cause increased smoke production. On vehicles without a DPF, this could be a sign of a damaged injector. Another alarming symptom is difficulty starting the Common Rail engine after a long period of inactivity, especially in winter conditions. The operation of the unit changes, and the motor itself emits stronger vibrations and unnatural noise. An unequivocal answer can be given by checking for overflow or diagnostics in the service.

How to care for common rail injectors in an engine? Use only proven fuel, change the fuel filter regularly, and don't experiment with "miracle" liquid products that injectors are supposed to regenerate. Their use can be counterproductive for their intended purpose. Caring for your nozzles will extend their life and you can avoid the not-so-low cost of replacement.