Reduction and reality

Concern for the environment has a lot to do with the automotive industry. Reduced CO2 emissions and tuning engines to increasingly stringent European standards have caused many carmakers to pull their hair out of their heads. One engine manufacturer even cheated by downloading engine software that worked differently during tests and inspections at diagnostic stations and differently during normal driving, which caused the company huge losses.

Concern for the environment has a lot to do with the automotive industry. Reduced CO2 emissions and tuning engines to increasingly stringent European standards have caused many carmakers to pull their hair out of their heads. One engine manufacturer even cheated by downloading engine software that worked differently during tests and inspections at diagnostic stations and differently during normal driving, which caused the company huge losses.

Manufacturers of many brands, including Fiat, Skoda, Renault, Ford, are moving towards downsizing to reduce exhaust emissions. Downsizing is associated with a reduction in engine power, and power equalization (to match the power of larger vehicles) is achieved through the addition of turbochargers, direct fuel injection and variable valve timing.

Manufacturers of many brands, including Fiat, Skoda, Renault, Ford, are moving towards downsizing to reduce exhaust emissions. Downsizing is associated with a reduction in engine power, and power equalization (to match the power of larger vehicles) is achieved through the addition of turbochargers, direct fuel injection and variable valve timing.

Let's think about whether such a change is really good for us? Manufacturers boast of low fuel consumption and high torque due to the use of a turbocharger. Can you trust them?

In the past, diesel folks knew very well what having a turbocharger meant. First, when starting the turbocharger, fuel consumption immediately increases. Secondly, this is another element that can lead to significant costs if used incorrectly.

The Americans have already proven in their tests that small turbocharged cars are not more economical in normal operation and accelerate worse than cars with larger naturally aspirated units.

When buying a car, looking through the catalog and the fuel consumption section, you are actually being deceived. Combustion catalog data is measured in the laboratory, not on the road.

How does pulling up engine power affect its wear?

It is safe to say that cars that have traveled hundreds of thousands of kilometers without a major overhaul, unfortunately, are no longer produced. Every car has to break down in order for the manufacturer to make money from parts and maintenance. I'm afraid, however, that powering the engines and drawing out 110 hp. of engines 1.2 certainly will not increase engine life. We don't have to worry about this when using a car with a warranty, but what if it runs out?

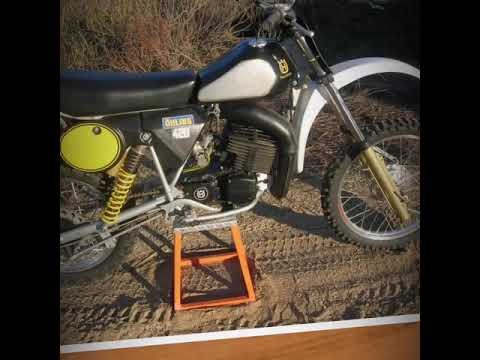

A simple example is motorcycle engines. There, even without a turbocharger, reaching 180 hp. with 1 liter of power - this is something normal. However, please note that motorcycles do not have high mileage. The new engines installed in them are unlikely to reach 100 km. If they get halfway through, it will still be a lot.

On the other hand, we can look at American cars. They have naturally aspirated engines of large displacement and relatively low power. One might wonder if it's not a coincidence that they cover long distances, given the distances Americans travel on their way to work.

Once we decide to buy a turbocharged car, how should we use the turbocharger?

The turbocharger is a very precise device. Its rotor spins at up to 250 revolutions per minute.

In order for the turbocharger to serve us for a long time and without fail, you should remember a few rules.

- We must take care of the correct amount of oil.

- The oil should not contain impurities, so it is important to change it in a timely manner in accordance with the recommendations of the car manufacturer.

- Keep an eye on the condition of the air intake system so that a foreign body does not get into it.

- Avoid abrupt shutdown of the vehicle and allow the turbine to cool down. For example, let the engine run for a few minutes during a break on a track where the turbine was running all the time.

What to do if the turbocharger is damaged?

The failure of a turbocharger in most cases is due to improper operation of the engine or one of its components. It rarely happens that it fails due to improper operation or wear.

When it fails after a manufacturer's warranty, we are faced with a choice: buy a new one or go through our regeneration. The latter solution will certainly be cheaper, but will it be effective?

The regeneration of a turbocharger consists in disassembling it into parts, thoroughly cleaning it in special tools, then replacing bearings, rings and o-rings. A damaged shaft or compression wheel must also be replaced. A very important stage is balancing the rotor, and then checking the quality of the turbocharger.

It turns out that the regeneration of a turbocharger is equivalent to buying a new one, because all its elements are checked and replaced. However, it is very important that a turbocharger remanufacturer has the appropriate equipment and works with original parts. It is also worth paying attention to whether they provide a guarantee for their services.

We won't change the times. It depends on us which car we choose, will it have a small capacity and a relatively large power? Or maybe take one that does not have a turbocharger? Electric vehicles are likely to dominate in the future anyway 😉

Text prepared by www.all4u.pl